Bendamustine hydrochloride crystal and preparation method thereof

A technology of bendamustine hydrochloride and bendamustine hydrochloride, which is applied in the field of polymorphic forms of bendamustine hydrochloride, can solve the problem that the solvent is difficult to meet the Pharmacopoeia standard, the impurity is difficult to reach 0.1%, and it is not suitable for industrial production and other problems, to achieve the effect of easy industrial production, controllable quality and stable yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

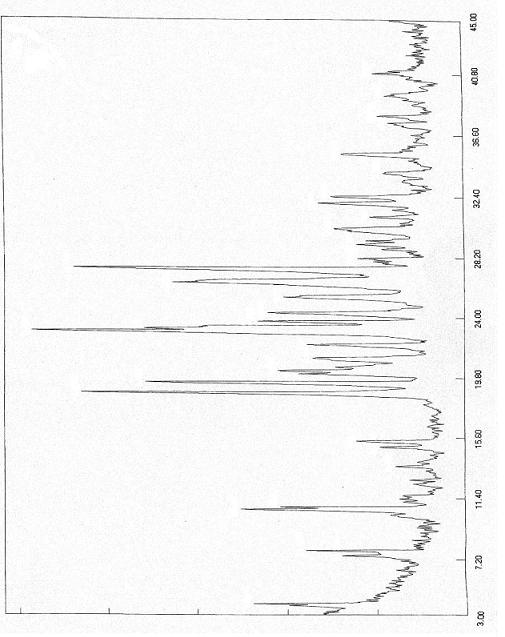

[0059] Example 1 Preparation of bendamustine hydrochloride polymorph I

[0060] Take 10 grams of crude bendamustine hydrochloride and place it in the reaction flask, add 50ml of 1mol / L hydrochloric acid solution, heat to 70~80℃, dissolve, slowly cool to room temperature and stir for 1 hour, then cool to 0~10℃ for precipitation Crystal for 5 hours. Filter, wash the filter cake with water and wash with acetone.

[0061] The obtained solid was added to the reaction flask, 300ml of acetone was added, heated to reflux and stirred for 2 hours, slowly cooled to room temperature and stirred for 1 hour, and then cooled to 0-10°C for 5 hours to crystallize. Filter, wash the filter cake with acetone, collect the solids, and dry at 45°C under reduced pressure (-0.09MPa) with phosphorus pentoxide for drying. 8.2 grams of white solid was obtained, the yield was 82%, and the purity was 99.92%. The X-diffraction data is the same as Table 1.

Embodiment 2

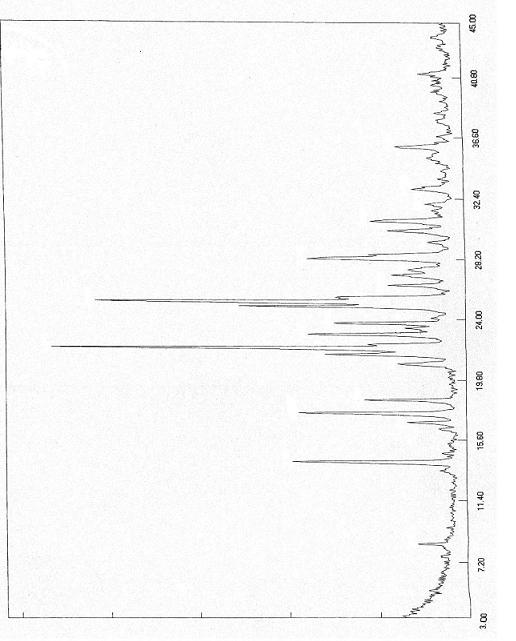

[0062] Example 2 Preparation of bendamustine hydrochloride polymorph I

[0063] Take 10 grams of crude bendamustine hydrochloride and place it in a reaction flask, add 40ml of 1mol / L hydrochloric acid solution, heat to 70~80℃, dissolve, slowly cool to room temperature and stir for 1 hour, then cool to 0~10℃ for precipitation Crystal for 5 hours. Filter, wash the filter cake with water and wash with acetone.

[0064] The obtained solid was added to the reaction flask, 400ml of acetone was added, heated to reflux and stirred for 2 hours, slowly cooled to room temperature and stirred for 1 hour, and then cooled to 0-10°C for 5 hours to crystallize. Filter, wash the filter cake with acetone, collect the solids, and dry at 45°C under reduced pressure (-0.09MPa) with phosphorus pentoxide for drying. 8.4 g of white solid was obtained, the yield was 84%, and the purity was 99.90%. The X-diffraction data is the same as Table 1.

Embodiment 3

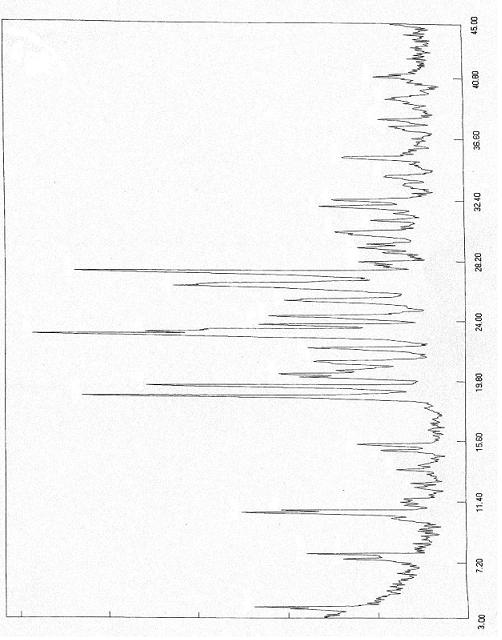

[0065] Example 3 Preparation of bendamustine hydrochloride polymorph I

[0066] Take 7.6 grams of crude bendamustine hydrochloride and place it in a reaction flask, add 45ml of 1mol / L hydrochloric acid solution, heat to 70~80℃, dissolve, slowly cool to room temperature and stir for 2 hours, then cool to 0~10℃ Crystal for 6 hours. Filter, wash the filter cake with water and wash with acetone.

[0067] Add the obtained solid to the reaction flask, add 270ml of acetone, heat to reflux and stir for 1.5 hours, slowly cool to room temperature and stir for 2 hours, then cool to 0-10°C for 8 hours to crystallize. Filter, wash the filter cake with acetone, collect the solids, and dry at 45°C under reduced pressure (-0.09MPa) with phosphorus pentoxide for drying. 8.0 g of white solid was obtained, the yield was 80%, and the purity was 99.96%. The X-diffraction data is the same as Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com