Ultraviolet (VU) offset printing transfer laser paint and synthesis method thereof

A technology that transfers lasers and synthetic methods, applied in the direction of coating, etc., can solve the problems of benzene escaping, not having resistance to ultraviolet light, etc., and achieve the effect of reducing damage and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

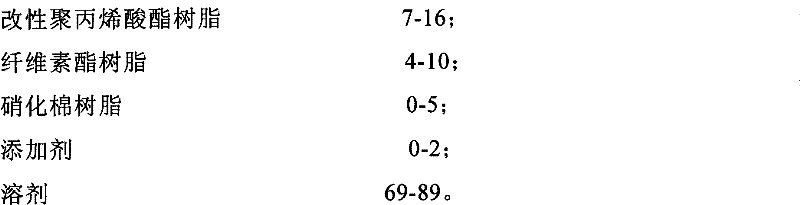

[0040] A method for preparing an environment-friendly laser transfer coating suitable for UV offset printing, the method comprising the following steps:

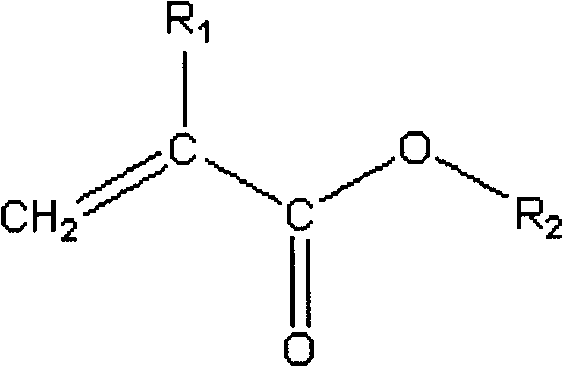

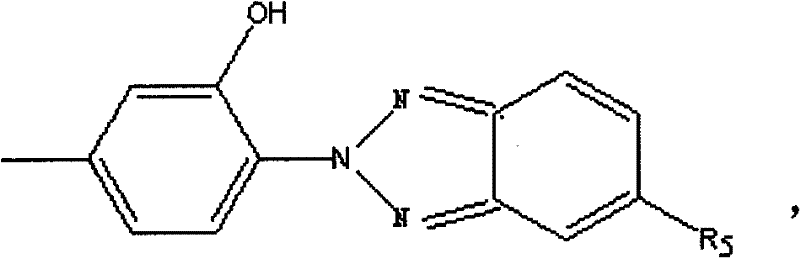

[0041] (1) Prepare raw materials according to the following components and content (wt%): modified polyacrylate resin 7%, cellulose ester resin 10%, nitrocellulose resin 4%, plasticizer 0.2%, leveling agent 0.4%, Ethyl acetate 20%, butanone 28.4%, n-propyl acetate 24%, propylene glycol methyl ether 6%; modified polyacrylate resin is methyl methacrylate monomer, butyl methacrylate monomer and modified acrylic acid The copolymer of ester monomer or modified methacrylate monomer, the cellulose is cellulose acetate propionate, the plasticizer is polyphenylmethylsiloxane, and the leveling agent is polyether modified polysiloxane alkyl.

[0042] (2) Put ethyl acetate, butanone, n-propyl acetate, and propylene glycol methyl ether as solvents in the reaction kettle, heat the reaction kettle to 60° C. and turn on the stirring device...

Embodiment 2

[0052] A method for preparing an environment-friendly laser transfer coating suitable for UV offset printing, the method comprising the following steps:

[0053] (1) Prepare raw materials according to the following components and contents (wt%): 10% of modified polyacrylate resin, 5% of cellulose ester resin, 2% of nitrocellulose resin; 0.1% of plasticizer, 20% of ethyl acetate, Butanone 32.9%, n-propyl acetate 30%; modified polyacrylate resin is methyl methacrylate monomer, butyl methacrylate monomer and modified acrylate monomer or modified methacrylate monomer The copolymer, the cellulose is cellulose acetate propionate, the nitrocellulose resin is 3 seconds nitrocellulose resin, and the plasticizer is polyphenylmethylsiloxane.

[0054] (2) Put ethyl acetate, butanone, and n-propyl acetate as solvents in the reactor, heat the reactor to 50° C. and start the stirring device to stir evenly;

[0055] (3) polyacrylic acid resin, cellulose resin and nitrocellulose resin are dro...

Embodiment 3

[0060] A method for preparing an environment-friendly laser transfer coating suitable for UV offset printing, the method comprising the following steps:

[0061] (1) Prepare raw materials according to the following components and content (wt%): modified polyacrylate resin 16%, cellulose ester resin 5%, leveling agent 0.2%, plasticizer 0.1%, ethyl acetate 30%, Butanone 30%, n-propyl acetate 18.7%. Modified polyacrylate resin is a copolymer of methyl methacrylate monomer, butyl methacrylate monomer and modified acrylate monomer or modified methacrylate monomer, and the cellulose is cellulose acetate butyrate , The leveling agent is polyether modified polysiloxane, and the plasticizer is polyphenylmethylsiloxane.

[0062] (2) Put ethyl acetate, butanone, and n-propyl acetate as solvents in the reactor, heat the reactor to 50° C. and start the stirring device to stir evenly;

[0063] (3) The modified polyacrylic acid resin and the cellulose resin are dropped into the reactor, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com