Naked oat seed coating agent and preparation method thereof

A technology of naked oat and dispersant, which is applied in the field of naked oat seed coating agent and its preparation, can solve the problems of dampening farmers' planting enthusiasm, time-consuming, low yield, etc., and achieve the reduction of spraying control times, obvious control effect, and lighten labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

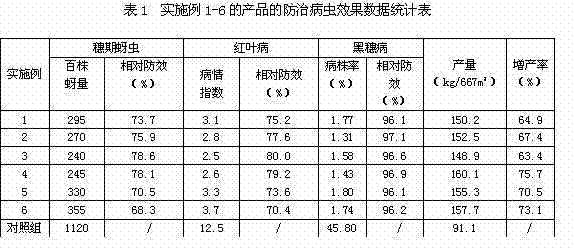

Examples

Embodiment 1

[0020] (1) Weigh each raw material by weight: Thiamethoxam 15%, Tebuconazole 0.05%, Dispersant 3%, Anticaking agent 2%, Suspending agent 1.5%, Film forming agent 2%, Filler 10% , preservative 1%, colorant 3%, water 60.45%.

[0021] Among them, thiamethoxam and tebuconazole are the original drugs with a content of 91%, the dispersant is nonylphenol polyoxyethylene ether: alkylphenol polyoxyethylene ether=2:5, the anticaking agent is tricalcium phosphate, and the suspension The agent is xanthan gum, the film-forming agent is polyvinyl alcohol, the filler is bentonite, the preservative is sodium benzoate, and the coloring agent is acid scarlet.

[0022] (2) Add powder raw materials such as original drug, filler, colorant, anti-caking agent into a homogenizer filled with water and mix for 30 minutes, then add liquid raw materials such as dispersant, film-forming agent, and preservative in sequence, and then mix and disperse For 10 minutes, a premixed slurry was formed.

[0023] ...

Embodiment 2

[0026] According to weight ratio, weigh each raw material: thiamethoxam 20%, tebuconazole 0.1%, dispersant 5%, anticaking agent 3.6%, suspending agent 2%, film forming agent 1.5%, filler 3%, preservative 1.5%, colorant 3%, water 60.3%.

[0027] Among them, thiamethoxam and tebuconazole are the original drugs with a content of 92%, the dispersant is phenethylphenol polyoxyethylene ether, the anticaking agent is silicon dioxide, and the suspending agent is xanthan gum and polyvinylpyrrolidine Ketone, the ratio is 4:1, the film-forming agent is polyvinyl acetate, the filler is kaolin and attapulgite clay, the ratio is 1:1, the preservative is industrial grade formaldehyde, and the colorant is acid scarlet.

[0028] The method for preparing the seed coating with the above raw materials is the same as in Example 1, the dispersion time of step (2) is 20 minutes, and the grinding time of step (3) is 0.7 hours.

Embodiment 3

[0030] Weigh each raw material by weight: 18% thiamethoxam, 0.07% tebuconazole, 2.4% dispersant, 2% anticaking agent, 1.5% suspending agent, 2% film forming agent, 7% filler, preservative 1%, colorant 3.5%, water 62.53%.

[0031] Among them, thiamethoxam and tebuconazole are the original drugs with a content of 93%, the dispersant is alkylphenol polyoxyethylene ether, the anticaking agent is sodium aluminosilicate, the suspending agent is xanthan gum, and the film forming agent is polyoxyethylene Vinyl alcohol, attapulgite clay as a filler, potassium sorbate as a preservative, and acid red B as a colorant.

[0032] The method of preparing the seed coating with the above raw materials is the same as in Example 1, the dispersion time of step (2) is 30 minutes, and the grinding time of step (3) is 0.9 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com