Epoxy resin composition, and prepreg material and printed circuit board prepared from the same

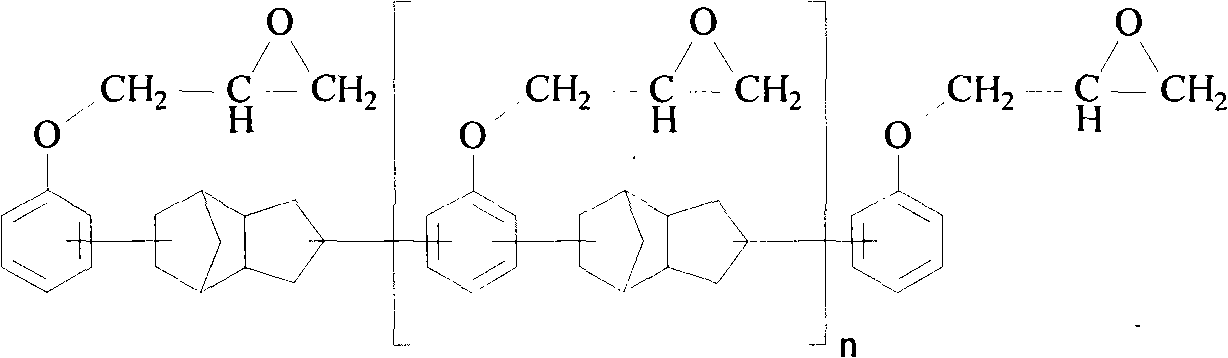

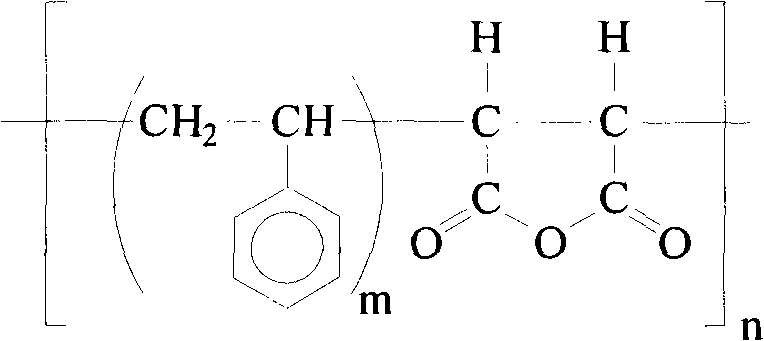

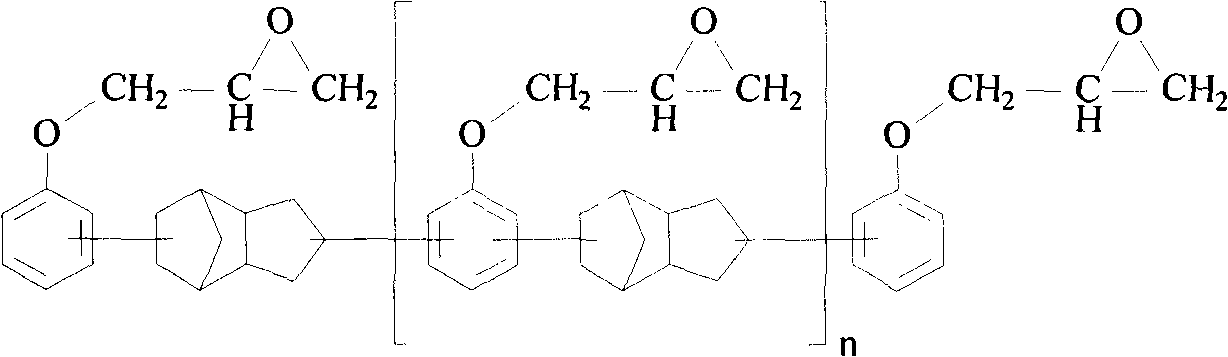

A technology of epoxy resin and phenolic epoxy resin, applied in the field of prepreg and printed circuit board, can solve the problems of easy generation of dust, excessive brittleness of laminated board, precipitation of crystals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 100 parts by weight of dicyclopentadiene (DCPD) type epoxy resin (epoxy equivalent weight (EEW): 279, Dainippon Printing HP-7200H), 40 parts by weight of styrene-maleic anhydride copolymer (molecular weight is 11,000 , the weight ratio of styrene to maleic anhydride is 4:1, Sartomer EF40), 0.5 parts by weight of tetrabutylphosphonium acetate (Deep Water), 0.5 parts by weight of silane coupling agent, 22 parts by weight of phosphazene polymer (Otsuka Chemical SPB-100), 15 parts by weight of phosphorus-containing (DOPO) bisphenol A type epoxy resin (Dow ChemicalXZ-92741), 2 parts by weight of carboxyl-terminated nitrile rubber (Hexion 58005) and 60 parts by weight Talc was mixed at room temperature using a stirrer for 60 minutes, and then 80 parts by weight of methyl ethyl ketone was added. After the above materials were stirred at room temperature for 120 minutes, an epoxy resin composition varnish was formed.

Embodiment 2

[0049] 100 parts by weight of dicyclopentadiene (DCPD) type epoxy resin (EEW: 279, Dainippon Printing HP-7200H), 30 parts by weight of styrene-maleic anhydride copolymer (molecular weight is 11,000, styrene to horse The weight ratio of anhydride is 4:1, Sartomer EF40), 0.5 parts by weight of tetrabutylphosphonium acetate (DeepWater), 0.5 parts by weight of silane coupling agent, 22 parts by weight of phosphazene macromolecule (Otsuka Chemical SPB- 100), 15 parts by weight of phosphorus-containing (DOPO) bisphenol A novolac epoxy resin (Dow ChemicalXZ-92741), 2 parts by weight of carboxyl-terminated nitrile rubber (Hexion 58005) and talc of 60 parts by weight, at room temperature After mixing for 60 minutes using a stirrer, 80 parts by weight of methyl ethyl ketone was added. After the above materials were stirred at room temperature for 120 minutes, an epoxy resin composition varnish was formed.

Embodiment 3

[0051] 100 parts by weight of dicyclopentadiene (DCPD) type epoxy resin (EEW: 279, Dainippon Printing HP-7200H), 80 parts by weight of styrene-maleic anhydride copolymer (molecular weight is 11,000, styrene to horse The weight ratio of anhydride is 4:1, Sartomer EF40), 0.5 parts by weight of tetrabutylphosphonium acetate (DeepWater), 0.5 parts by weight of silane coupling agent, 22 parts by weight of phosphazene macromolecule (Otsuka Chemical SPB- 100), 15 parts by weight of phosphorus-containing (DOPO) bisphenol A novolac epoxy resin (Dow ChemicalXZ-92741), 2 parts by weight of carboxyl-terminated nitrile rubber (Hexion 58005) and talc of 60 parts by weight, at room temperature After mixing for 60 minutes using a stirrer, 80 parts by weight of methyl ethyl ketone was added. After the above materials were stirred at room temperature for 120 minutes, an epoxy resin composition varnish was formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com