Method for preparing magnetic metal-metal core-shell nano particles

A magnetic metal nanometer and magnetic metal technology, applied in the coating and other directions, can solve the problems of low cladding rate, easy nucleation of shell metal, and difficulty in controlling the formation of shell metal. Wide, ensure the effect of effective coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

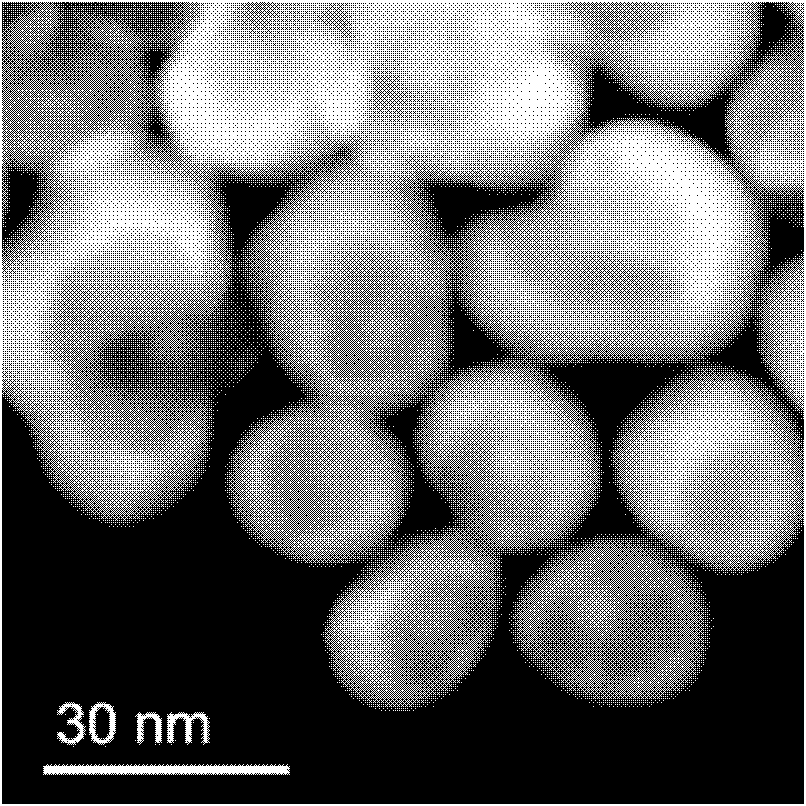

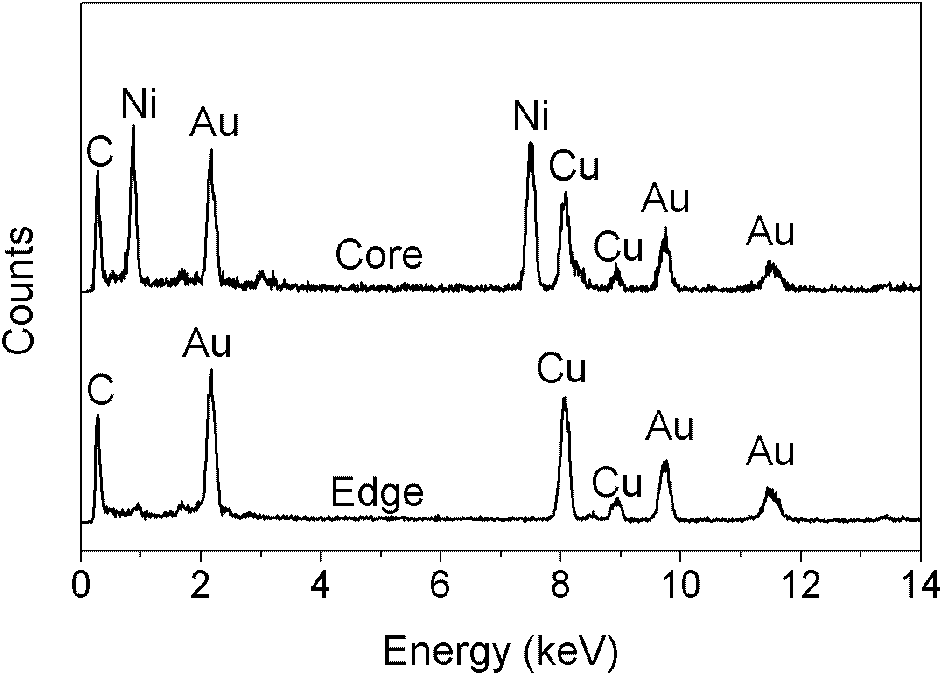

[0033] Add 0.5mmol nickel acetylacetonate and 6ml oleylamine into a three-necked flask, stir and mix under the protection of argon, then add a mixture of 0.012mmol chloroauric acid and 0.3ml anisole into the three-necked flask, stir for 10min and then heat to Hold at 50°C for 10 minutes, then heat to 200°C, hold for 20 minutes, and then cool to 150°C. Quickly inject a mixture of 0.5mmol of the pre-prepared gold organic compound and 2ml of chloroform, keep it at 140°C for 30 minutes and then cool it naturally, add acetone to precipitate the nanoparticles, take out the reaction mother liquor by centrifugation, and then use a mixed solution of ethanol, acetone and n-hexane Repeated washing, centrifugation three times, and finally vacuum drying to obtain a powder product. The electron micrograph and energy spectrum are as shown figure 1 with figure 2 Shown.

Embodiment 2

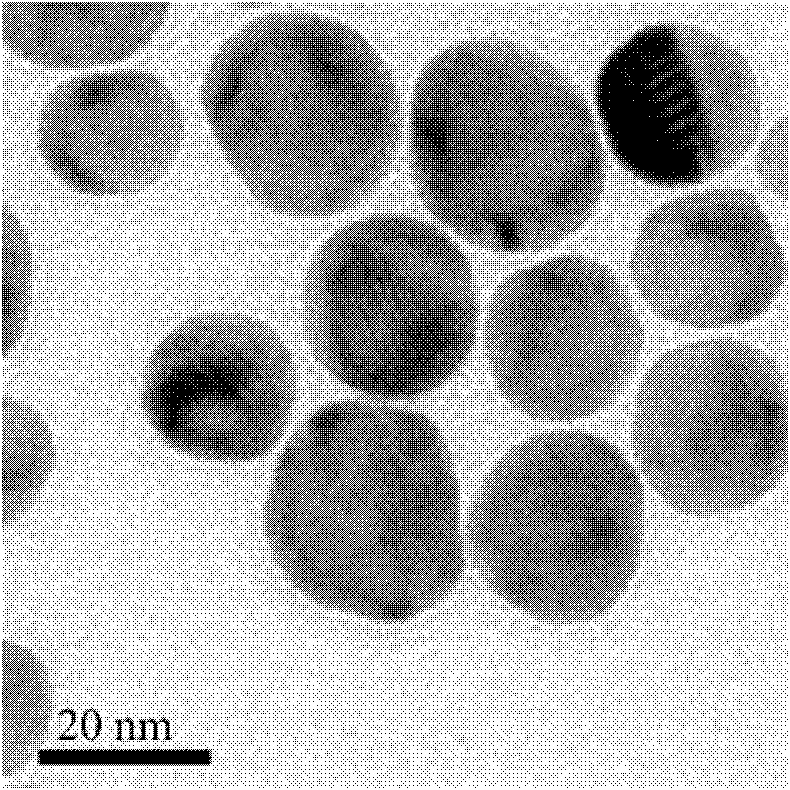

[0035] Add 0.5mmol nickel acetylacetonate and 6ml oleylamine into a three-necked flask, stir and mix under the protection of argon, then add a mixture of 0.012mmol chloroauric acid and 0.3ml ethanol into the three-necked flask, stir for 10min and then raise the temperature to 50℃ , Keep for 10min, then heat up to 200℃, keep for 20min, then cool to 150℃. Quickly inject a mixture of 0.5mmol of pre-prepared gold organic compound and 2ml of chloroform, keep it at 130°C for 30 minutes and then cool it naturally, add acetone to precipitate the nanoparticles, take out the reaction mother liquor by centrifugation, and then use a mixed solution of ethanol, acetone and n-hexane Repeated washing, centrifugation for 3 times, and finally vacuum drying to obtain a powder product. The electron microscope picture is as follows image 3 As shown, its energy spectrum and figure 2 similar.

Embodiment 3

[0037] Add 0.5mmol nickel acetylacetonate, 5ml oleylamine, 2ml dodecylamine into a three-necked flask, stir and mix under the protection of argon, then add a mixture of 0.012mmol chloroauric acid and 0.3ml toluene into the three-necked flask, and stir for 10min Then the temperature was raised to 50°C, the temperature was kept for 10 minutes, then the temperature was raised to 210°C, the temperature was kept for 20 minutes, and then it was cooled to 150°C. Quickly inject a mixture of 0.3mmol of the pre-prepared gold organic compound and 3ml of chloroform, keep it at 130°C for 30 minutes and then cool it naturally, add acetone to precipitate the nanoparticles, take out the reaction mother liquor by centrifugation, and then use a mixed solution of ethanol, acetone and n-hexane Repeated washing, centrifugation for three times, and finally vacuum drying to obtain a powder product. The electron microscope image is as follows Figure 4 As shown, its energy spectrum and figure 2 simila...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com