High-performance lithium ion phosphate materials prepared by microwave method and preparation method of high-performance lithium ion phosphate materials

A lithium iron phosphate, high-performance technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as high external temperature, achieve strong practicability, excellent rate performance, and remarkable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 (comparative test)

[0046] Select ferric oxide, lithium hydroxide and ammonium dihydrogen phosphate as raw materials, weigh them according to the ratio of molar ratio Fe: Li: P = 1: 1.02: 1, and place them in an aqueous solution so that the solid content reaches 40%. After mixing for 7 hours until uniform, spray-dried, then placed in a resistance heating furnace, heat-treated at 350°C for 2h under the protection of argon, then heat-treated at 650°C for 1h and then cooled to room temperature to obtain the desired lithium iron phosphate material .

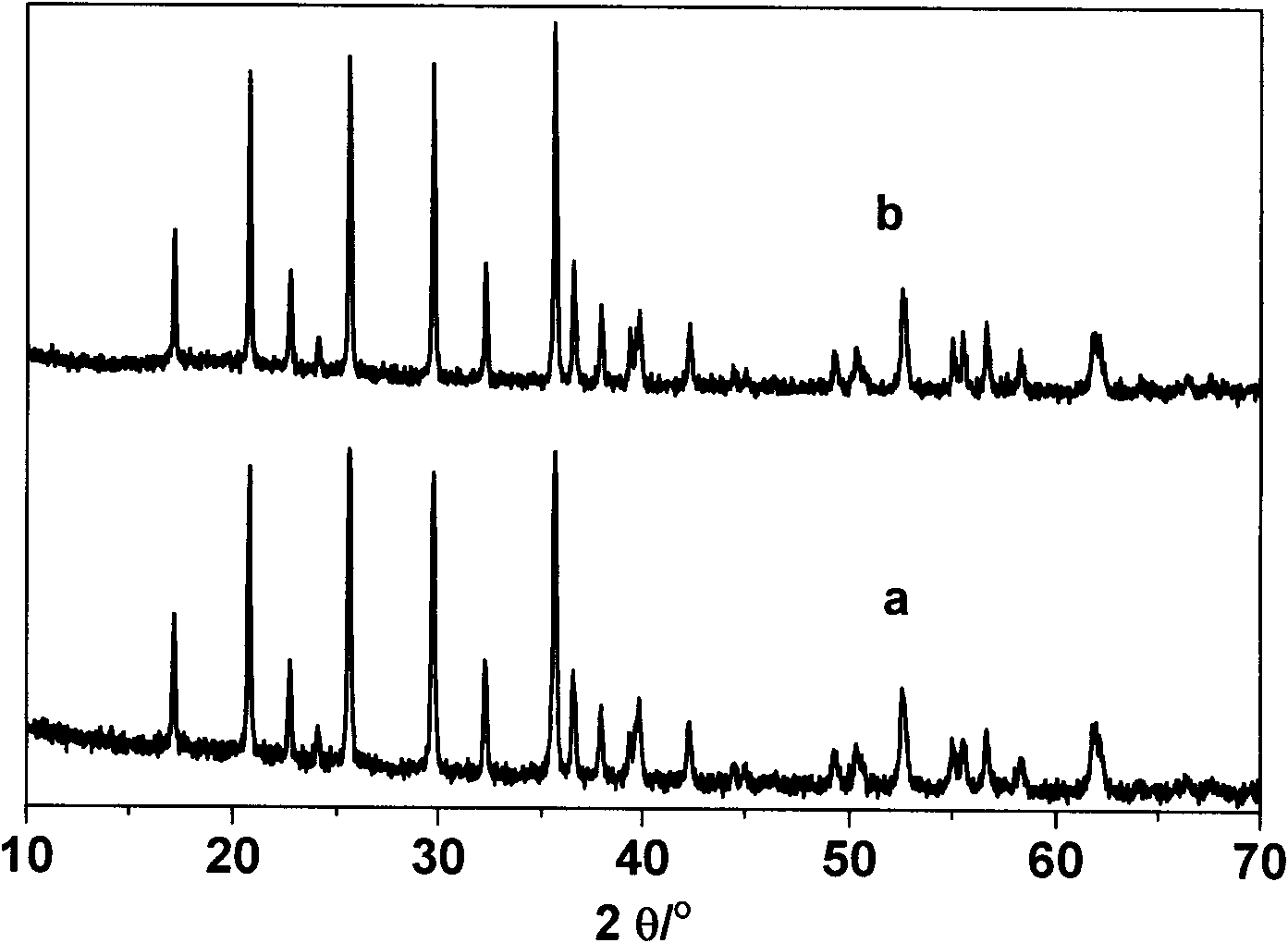

[0047] The XRD of the obtained material is shown in figure 1 a, it can be seen that the material is pure phase LiFePO 4 .

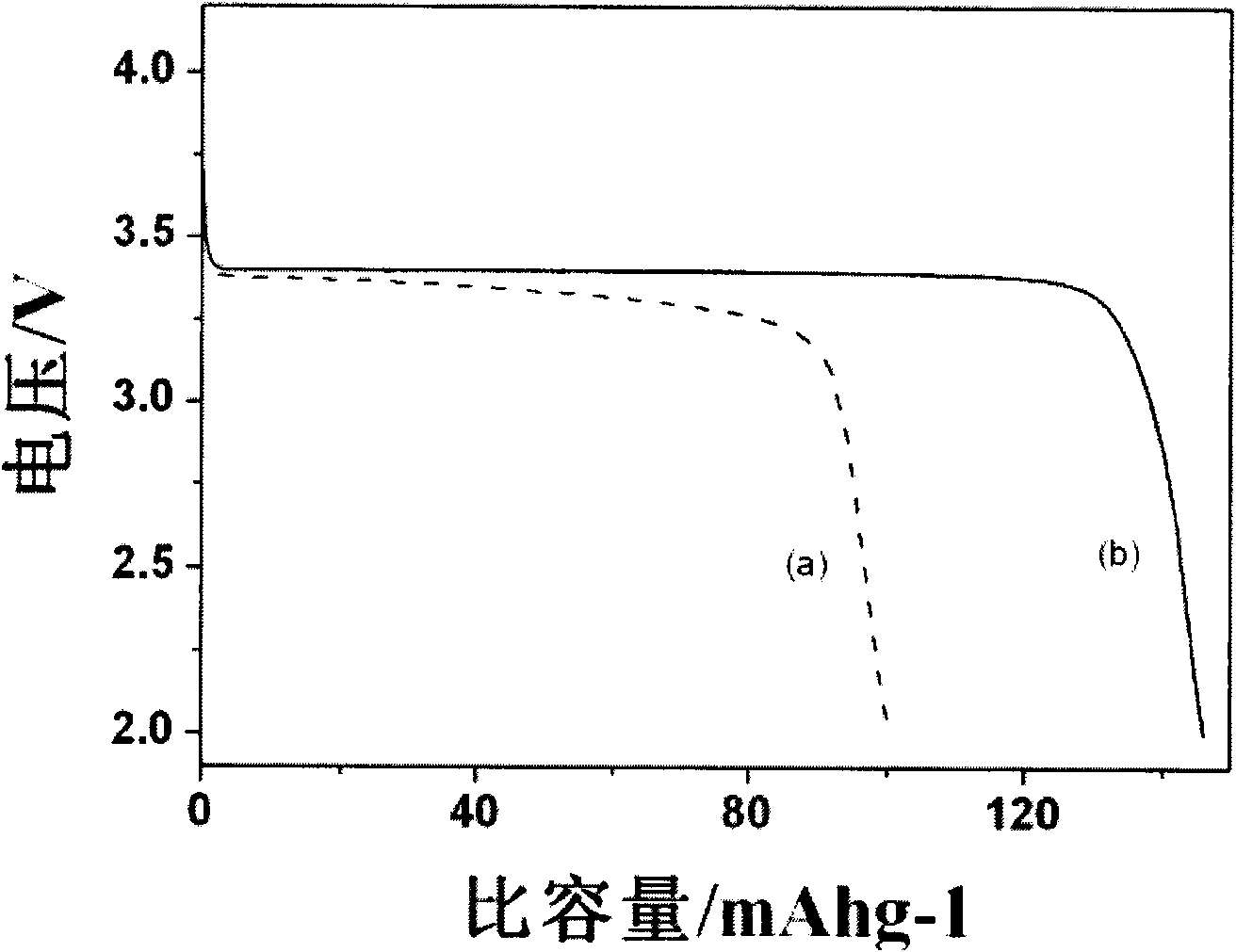

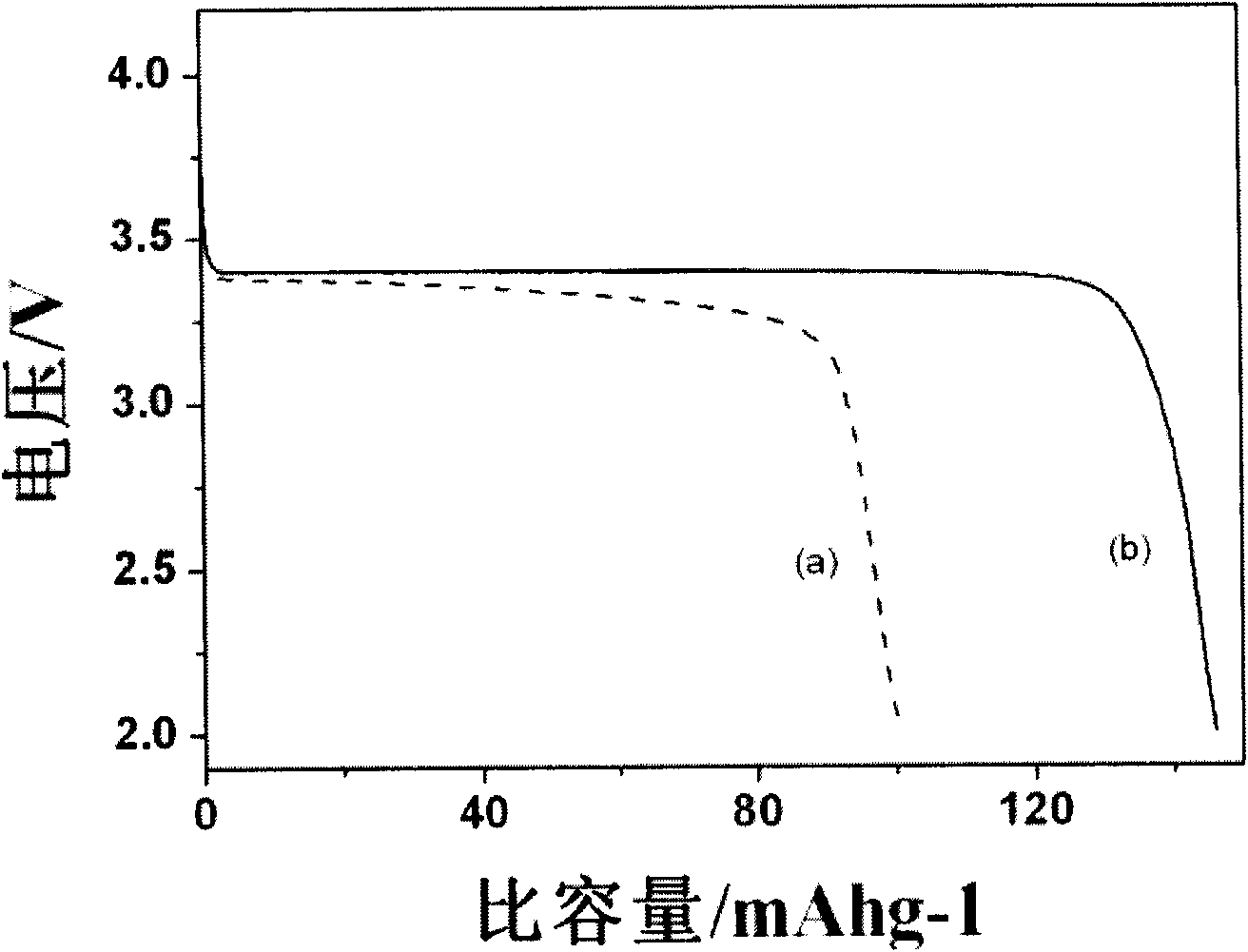

[0048] Electrochemical tests showed that ( figure 2 a), the capacity of the material is 101mAh / g when charged and discharged at 5C, and the conductivity of the material is 2X10 -6 S / cm.

Embodiment 2

[0050] Select ferric oxide, lithium hydroxide and ammonium dihydrogen phosphate as raw materials, weigh them according to the ratio of molar ratio Fe: Li: P = 1: 1.02: 1, and place them in an aqueous solution so that the solid content reaches 40%. After mixing for 7 hours until uniform, spray-dried, then placed in a microwave heating furnace (where ferric oxide is the main microwave absorber), heat-treated at 350°C for 2h under the protection of argon, then heat-treated at 650°C for 1h and then cooled to room temperature to obtain the desired lithium iron phosphate material.

[0051] The XRD of the obtained material is shown in figure 1 b, it can be seen that the material is pure phase LiFePO 4 .

[0052] Electrochemical tests showed that ( figure 2 b), the capacity of the material is 144mAh / g when charged and discharged at 5C, and the conductivity of the material is 3.8X10 -5 S / cm.

Embodiment 3

[0054] Select ferrous oxalate, lithium nitrate and ammonium dihydrogen phosphate raw materials, weigh them according to the ratio of molar ratio Fe: Li: P = 1: 1.02: 1, place them in acetone solution, make the solid content reach 40%, and then add the above raw materials Mass 1% Co 3 o 4 , mixed in a high-energy ball mill for 7 hours until uniform, spray-dried, and then placed in a microwave oven (where Co 3 o 4 is the main microwave absorber), heat treatment at 350°C for 2h under the protection of argon, then heat treatment at 650°C for 2h and then cool to room temperature to obtain the desired lithium iron phosphate material.

[0055] The resulting material is pure phase LiFePO 4 . Electrochemical tests show that when charging and discharging at 5C, the capacity of the material is 150mAh / g, and the conductivity of the material is 5.1X10 -4 S / cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com