Method by utilizing all-volatility headspace gas chromatography to measure content of alkoxy

A headspace gas chromatography and alkoxy technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of corrosion, interference, volatile component analysis, etc., to avoid corrosion, save time, and achieve continuity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Solution preparation

[0035] Internal standard solution: add 10mL o-xylene to a 100mL volumetric flask, then add 2.5g of toluene, and finally dilute to 100mL with o-xylene.

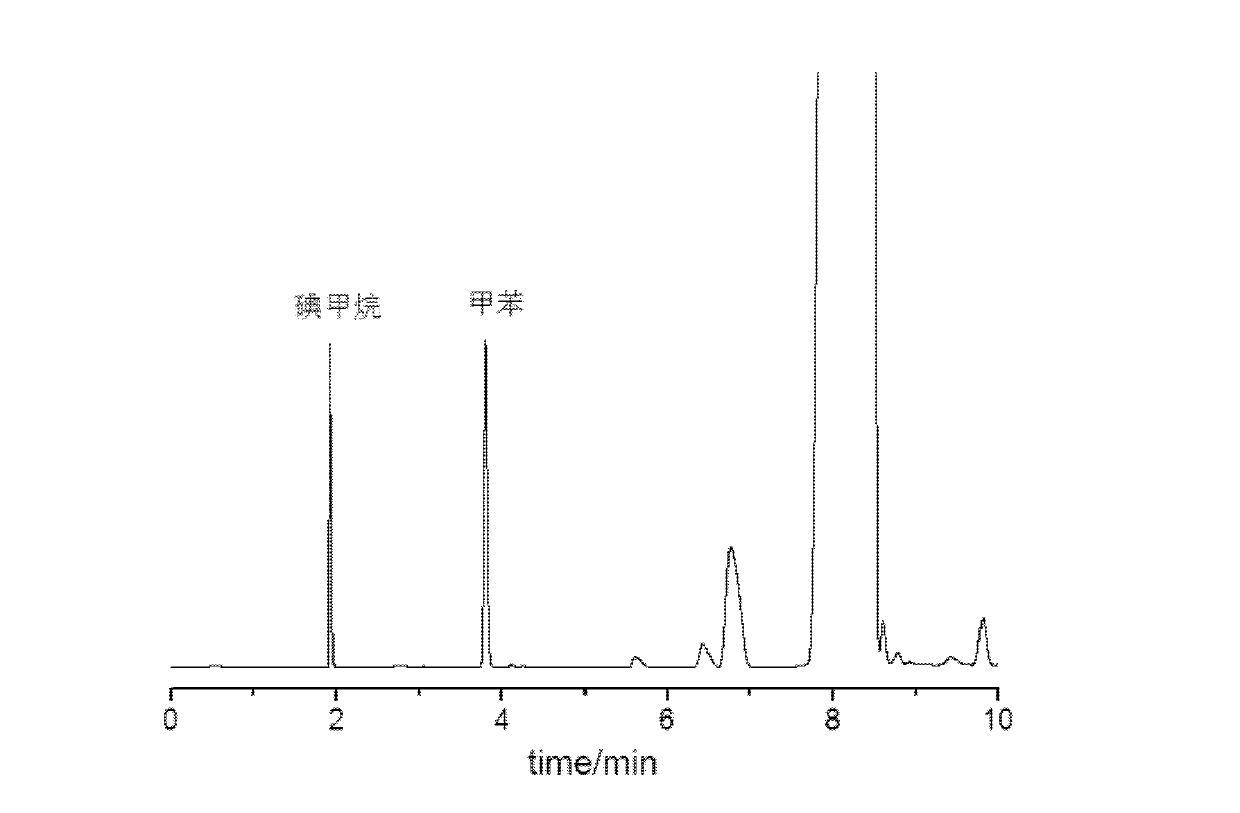

[0036] Standard solution: Add 20mg of adipic acid, 1mL of internal standard solution, 0.5mL of 8mol / L NaOH solution, and 0.5mL of 57% HI solution to the headspace bottle, and seal. Add 2, 4, 6, 8, 10, 15, 20 μL of methyl iodide to microsyringe puncture, accurately weigh, record the exact added mass of methyl iodide, use microsyringe to draw 30μL of supernatant into the headspace bottle and press the cap Seal, sample numbers 1, 2, 3, 4, 5, 6, and 7 respectively.

[0037] Sample solution: Add 20 mg of adipic acid, 10 mg of methyl cellulose, 1 mL of internal standard solution, and 0.5 mL of 57% HI solution to the headspace bottle, and seal it. Weigh the headspace bottle and shake the sample for 30 seconds. The headspace bottle was placed in a thermostat at 140°C for 2 hours, and the sample was shaken...

Embodiment 2

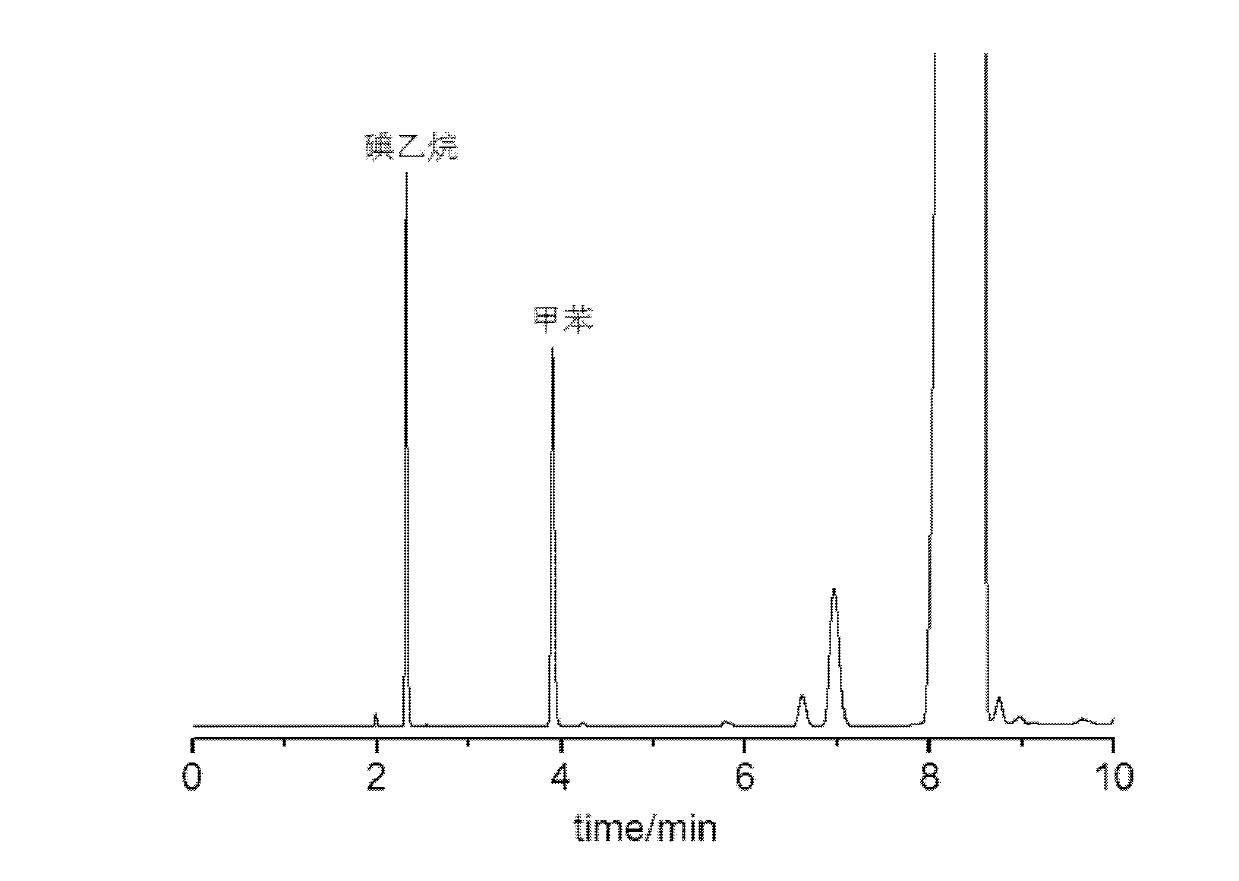

[0052] The difference between this embodiment and Embodiment 1 is:

[0053] Accurately weigh 10 mg of pharmaceutical grade ethyl cellulose sample (DOW Chemical Company), 5 parts in total, add 20 mg of adipic acid, 1 mL of internal standard solution, and 0.5 mL of 57% HI solution into a headspace bottle and seal it. Weigh the headspace bottle and shake the sample for 30 seconds. The headspace bottle was placed in a thermostat at 150°C for 1.5 hours, and the sample was shaken every 30 minutes for 30 seconds. Cool to room temperature and re-weigh to confirm that there is no leakage. Add 0.5 mL of 8mol / L NaoH solution to the syringe to neutralize the remaining HI. Withdraw 30 μL of supernatant into the headspace bottle, press the cap and seal, and analyze by fully volatile headspace sampling, and the measured ethoxy content is 48.7%.

Embodiment 3

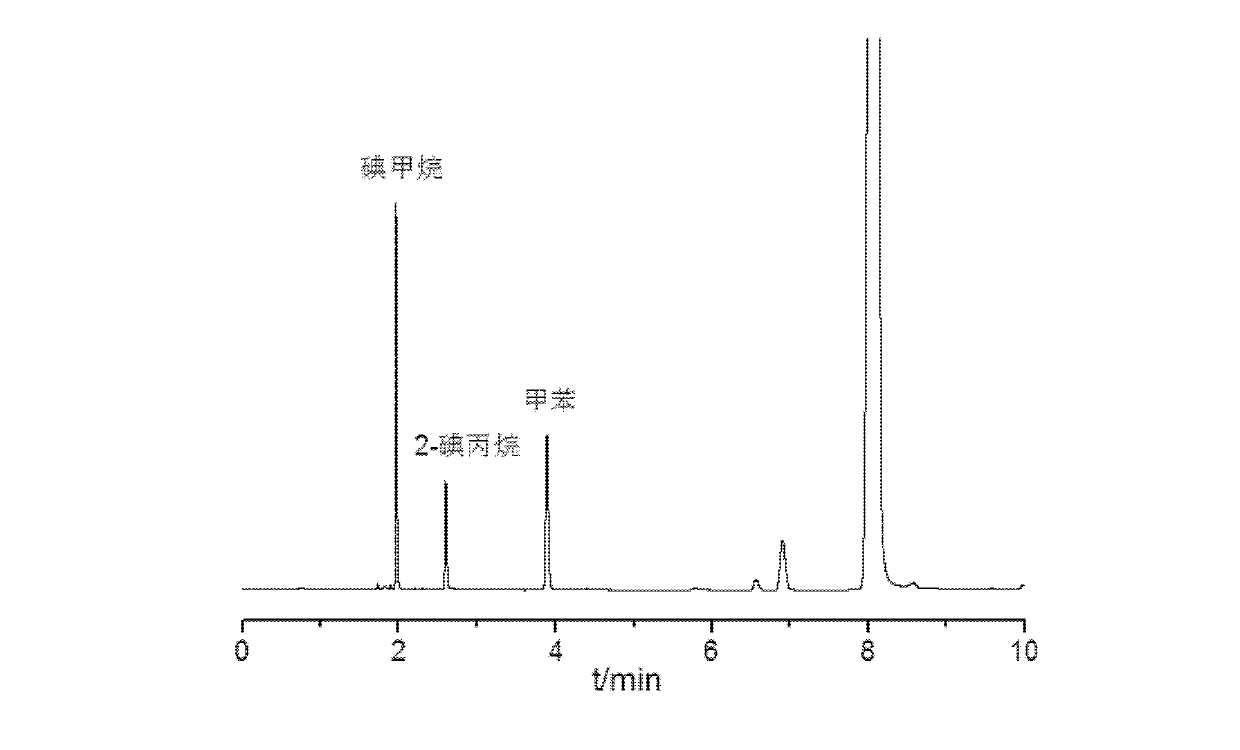

[0055] The difference between this embodiment and Embodiment 1 is:

[0056] Accurately weigh 10 mg of pharmaceutical grade hydroxypropyl methylcellulose sample (Shandong Heda Co., Ltd.), 5 parts in total, add 20 mg of adipic acid, 1 mL of internal standard solution, and 0.5 mL of 57% HI solution into the headspace bottle and seal it . Weigh the headspace bottle and shake the sample for 30 seconds. The headspace bottle was placed in a thermostat at 140°C for 2 hours, and the sample was shaken every 30 minutes for 30 seconds. Cool to room temperature and re-weigh to confirm that there is no leakage. Add 0.5 mL of 8mol / L NaoH solution to the syringe to neutralize the remaining HI. Withdraw 20 μL of supernatant into the headspace bottle, press the cap and seal, and analyze by fully volatile headspace sampling. The measured content of methoxy group is 15.8% and the content of hydroxypropoxy group is 22.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com