Manufacturing method of flexible electronic device

A technology of flexible electronic devices and manufacturing methods, which is applied in the direction of electric solid devices, discharge tube/lamp manufacturing, semiconductor/solid device manufacturing, etc., can solve problems such as device failure, difficulty in maintaining a flat shape, and rupture of inorganic thin film materials, and achieve Effects of low thermal expansion coefficient, small surface roughness, and high transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

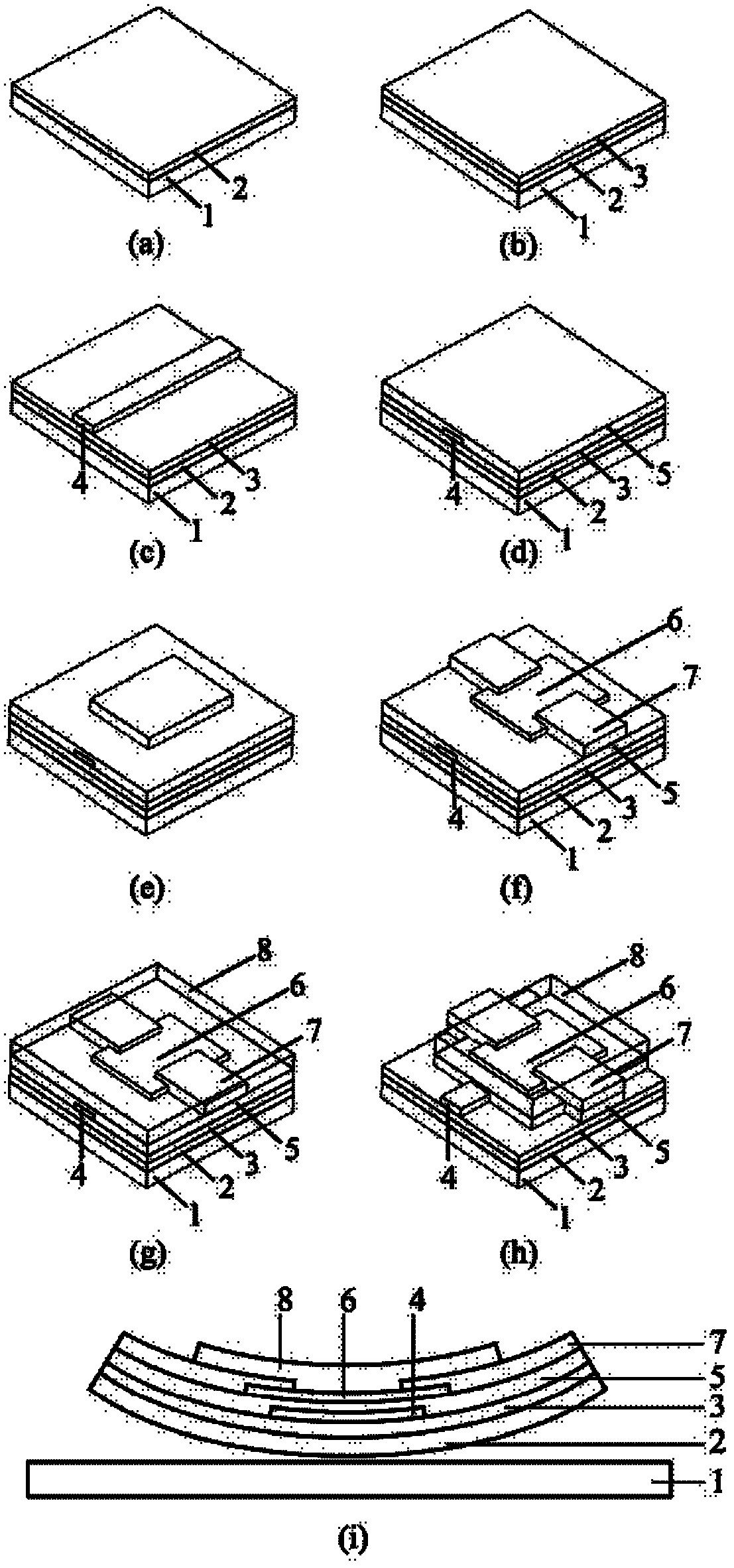

[0024] Fabrication of flexible amorphous indium gallium zinc oxide (a-IGZO) thin film transistor (TFT), the specific process is as follows:

[0025] like figure 1 As shown in (a), a glass substrate 1 coated with an indium tin oxide (ITO) film is used as a substrate coated with a polyimide film. The prepared polyamic acid solution was evenly scraped on the surface of the ITO glass substrate, and then the sample was placed in a vacuum oven for baking. Oven heating conditions: from room temperature to 130°C for 1 hour, heat preservation for 0.1 hour; then heat up for 0.2 hours to 190°C, heat preservation for 0.1 hour; 0.2 hours. After the reaction, a polyimide film 2 containing a thioether structure is obtained on the surface of the ITO glass.

[0026] like figure 1 As shown in (b), a layer of silicon nitride film 3 with a thickness of 200nm is deposited on the surface of the polyimide film with a sulfide structure by using plasma chemical enhanced deposition technology (PECV...

Embodiment 2

[0040] Preparation of flexible zinc oxide (ZnO) nanowire cold cathode, the specific process is as follows:

[0041] like image 3 As shown in (a), a glass substrate 11 coated with indium tin oxide (ITO) is used as the substrate for coating the polyimide film. The prepared polyamic acid solution was evenly scraped on the surface of the ITO glass substrate, and then the sample was placed in a vacuum oven for baking. Oven heating conditions: from room temperature to 130°C for 1 hour, heat preservation for 0.1 hour; then heat up for 0.2 hours to 190°C, heat preservation for 0.1 hour; 0.2 hours. After the reaction, a polyimide film 12 containing a thioether structure is obtained on the surface of the ITO glass.

[0042] like image 3 As shown in (b), the silicon nitride (SiNx) film 13 (which can also be materials such as silicon dioxide or aluminum oxide) with a thickness of 200 nm is deposited on the surface of the polyimide film containing the sulfide structure by PECVD, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com