Urea phosphate production method

A technology of urea phosphate and phosphoric acid solution, applied in ammonium orthophosphate fertilizers, chemical instruments and methods, alkaline orthophosphate fertilizers, etc., can solve the problem of low total recovery rate of phosphorus and nitrogen, inability to continuously produce feed products, and production costs Advanced problems, to achieve the effect of increasing hydrogen ion concentration, low cost, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

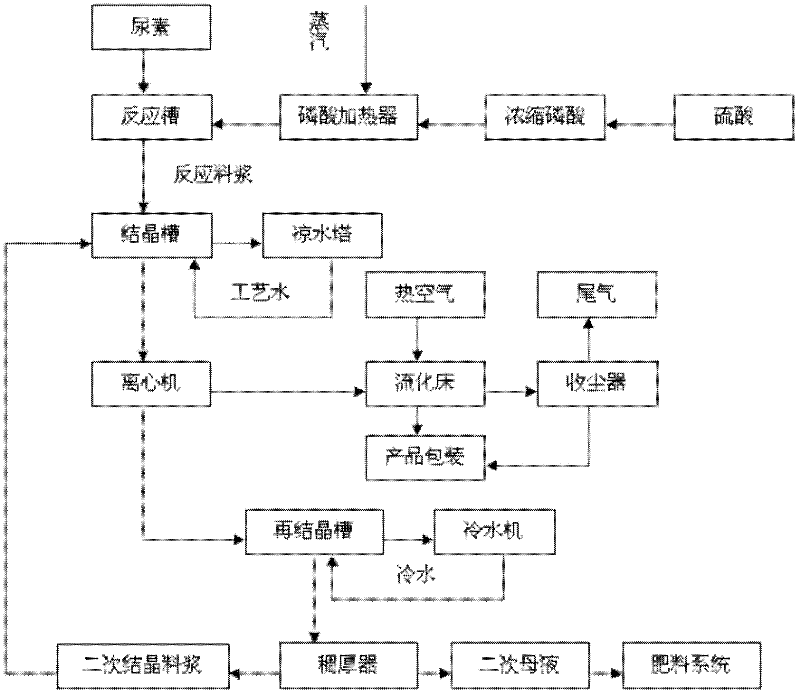

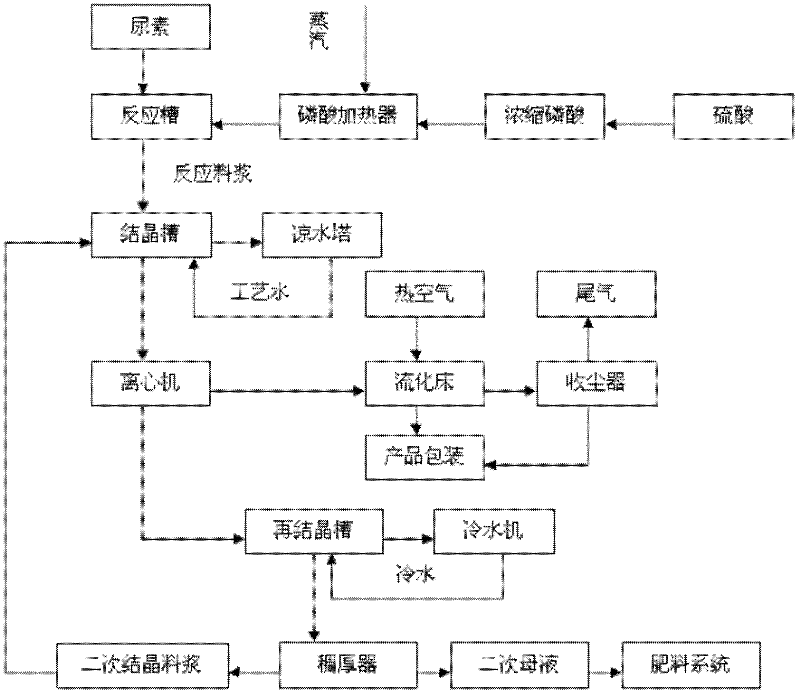

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 adopts the inventive method to produce urea phosphate

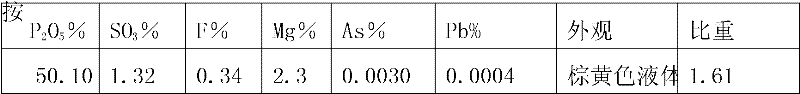

[0042] The indicators of the raw material phosphoric acid used are shown in Table 1.

[0043] The index of table 1 raw material phosphoric acid

[0044]

[0045] Follow the steps below for production:

[0046] (1) add sulfuric acid to raw material phosphoric acid, heat up and react:

[0047] Phosphoric acid from the wet system, temperature 72 ° C, through the phosphoric acid flow meter at 1.45m 3 The flow rate of / h enters the acid distribution tank and the sulfuric acid (sulfuric acid concentration 98wt%) from the sulfuric acid storage tank is measured by 0.087m 3 The flow rate of / h is used for acid mixing, and the stirring and mixing are pumped into the heat exchanger for circulation heating. The heating medium is low-pressure steam, the pressure is 0.2-0.6MPa, the mixed acid solution is heated to 75-80°C, and the outlet valve of the circulation pump is opened to continue Supply acid to the r...

Embodiment 2

[0057] Embodiment 2 adopts the inventive method to produce urea phosphate

[0058] The indicators of the raw material phosphoric acid used are shown in Table 3.

[0059] Table 3 Index of Raw Phosphoric Acid

[0060] P 2 o 5 %

SO 3 %

F%

Mg%

As%

Pb%

Exterior

54.0

1.36

0.40

2.4

0.0030

0.0004

brownish yellow liquid

1.66

[0061] Follow the steps below for production:

[0062] (1) add sulfuric acid to raw material phosphoric acid, heat up and react:

[0063] Phosphoric acid from the wet process system, temperature 72 ° C, through the phosphoric acid flow meter at 1.24m 3 The flow rate of / h enters the acid distribution tank and the sulfuric acid (sulfuric acid concentration 93wt%) from the sulfuric acid storage tank is measured by sulfuric acid at 0.060m 3 The flow rate of / h is used to prepare acid, and the stirring and mixing are pumped into the heat exchange...

Embodiment 3

[0073] Embodiment 3 adopts the inventive method to produce urea phosphate

[0074] The indicators of the raw material phosphoric acid used are shown in Table 5.

[0075] Table 5 Index of Raw Phosphoric Acid

[0076] P 2 o 5 %

SO 3 %

F%

Mg%

As%

Pb%

Exterior

58.0

2.36

0.30

2.3

0.0030

0.0004

brownish yellow liquid

1.72

[0077] Follow the steps below for production:

[0078] (1) add sulfuric acid to raw material phosphoric acid, heat up and react:

[0079] Phosphoric acid from the wet system, temperature 72 ° C, through the phosphoric acid flow meter at 1.45m 3 The flow rate of / h enters the acid distribution tank and the sulfuric acid (sulfuric acid concentration 98wt%) from the sulfuric acid storage tank is measured by sulfuric acid at 0.050m 3 The flow rate of / h is used to prepare acid, and the stirring and mixing are pumped into the heat exchanger for ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com