Preparation method of modified elm bark flocculant

A technology of elm bark and flocculants, which is applied in the field of preparation of modified elm bark flocculants, can solve the problems of poor electrical neutralization, difficulty, and difficulty in storage, and achieve resource and energy saving, good safety, and raw material saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

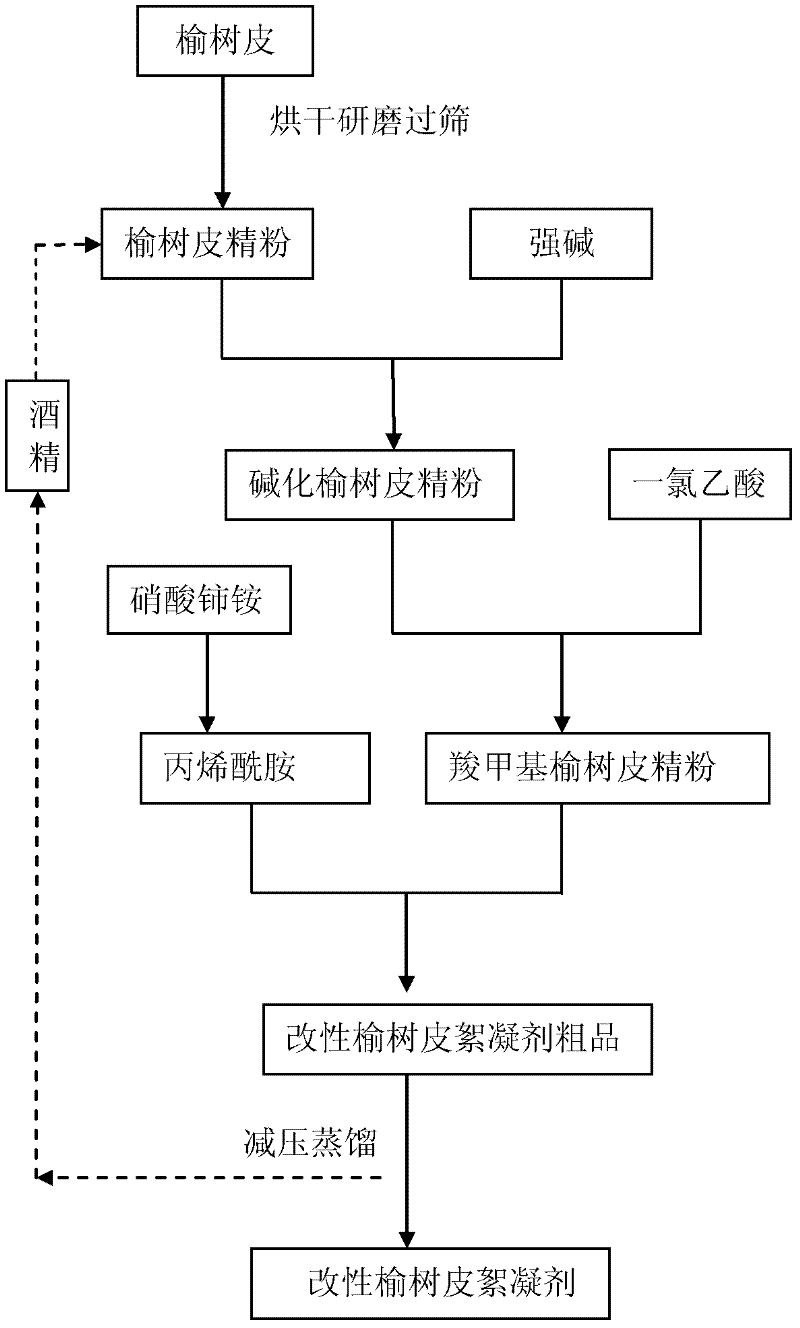

Method used

Image

Examples

Embodiment 1

[0034] (1) get 1000kg fresh elm bark, dry in the sun after exfoliating, grind through a 50 mesh sieve, get the elm bark fine powder with a moisture content of 5% by mass for subsequent use;

[0035] (2) Take by weighing 100g of elm bark fine powder with a moisture content of 5% and add it to a three-necked flask, moisten it with 150mL85% by mass alcohol, add 50mL of 10% by mass NaOH solution, insert a condensation reflux device, and React under stirring condition for 0.5h, obtain brown-red alkalized elm bark fine powder;

[0036] (3) Pour 20mL of industrial pure monochloroacetic acid into the reactor to make it etherify with the alkalized elm bark powder, and stir the reaction time at 70°C for 1h to obtain brown-red carboxymethylated elm bark powder, realizing Anion modification of elm bark fine powder;

[0037] (4) Add 1mL of 1% by mass cerium ammonium nitrate aqueous solution to the carboxymethylated elm bark fine powder in step (2), stir and activate, add 50g of acrylamide...

Embodiment 2

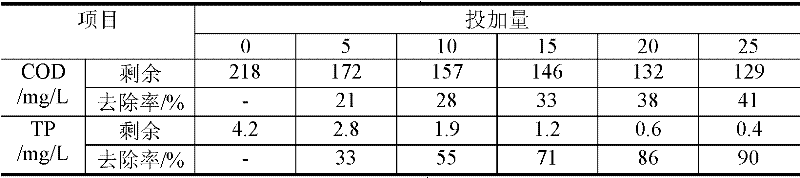

[0040] Take 6 250mL beakers, add 200mL of domestic sewage (COD218mg / L, TP4.2mg / L), add 0, 5, 10, 15, 20, 25ppm of the elm bark modified flocculant obtained in Example 1, and stir for 1min , stirred slowly for 14 minutes, and after settling for 30 minutes, take the supernatant to measure the COD and TP of the wastewater, see Table 1.

[0041] Table 1 The effect of the dosage of modified elm bark flocculant on the removal of domestic sewage

[0042]

[0043] It can be seen from Table 1 that COD and TP gradually increase with the increase of the dosage of modified elm bark flocculant. The removal does not have much impact, so it is determined that the best dosage for domestic sewage treatment is 20-25ppm.

Embodiment 3

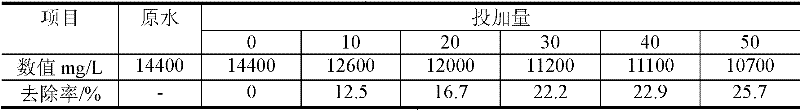

[0045] Take 6 250mL beakers, add 200mL of landfill leachate, add 0, 10, 20, 30, 40, 50ppm of the elm bark modified flocculant obtained in Example 1, stir quickly for 1min, stir slowly for 14min, and take out after 30min of precipitation. See Table 2 for the COD of the waste water measured in the supernatant.

[0046] Table 2 Effect of modified flocculant dosage on leachate removal

[0047]

[0048] It can be seen from Table 1 that COD gradually increases with the increase of the dosage of modified flocculant. When the dosage exceeds 50ppm, the removal rate does not change much, indicating that the excess flocculant does not have much effect on the COD of wastewater. Therefore, it is determined that the optimal dosage of landfill leachate is 50ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com