Environmentally friendly fabric fire retardant and its preparation method and use

A flame retardant and environment-friendly technology, applied in the field of silicon-containing phosphonate reactive flame retardant and its preparation, can solve problems such as restricting use, and achieve the effects of no formaldehyde release, simple preparation process and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

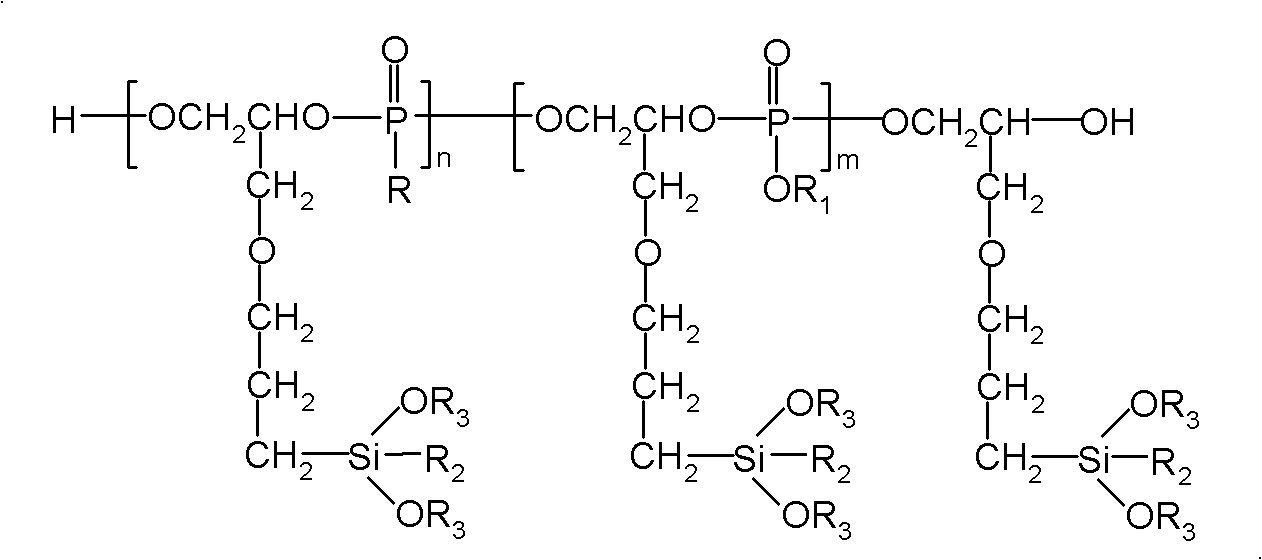

Method used

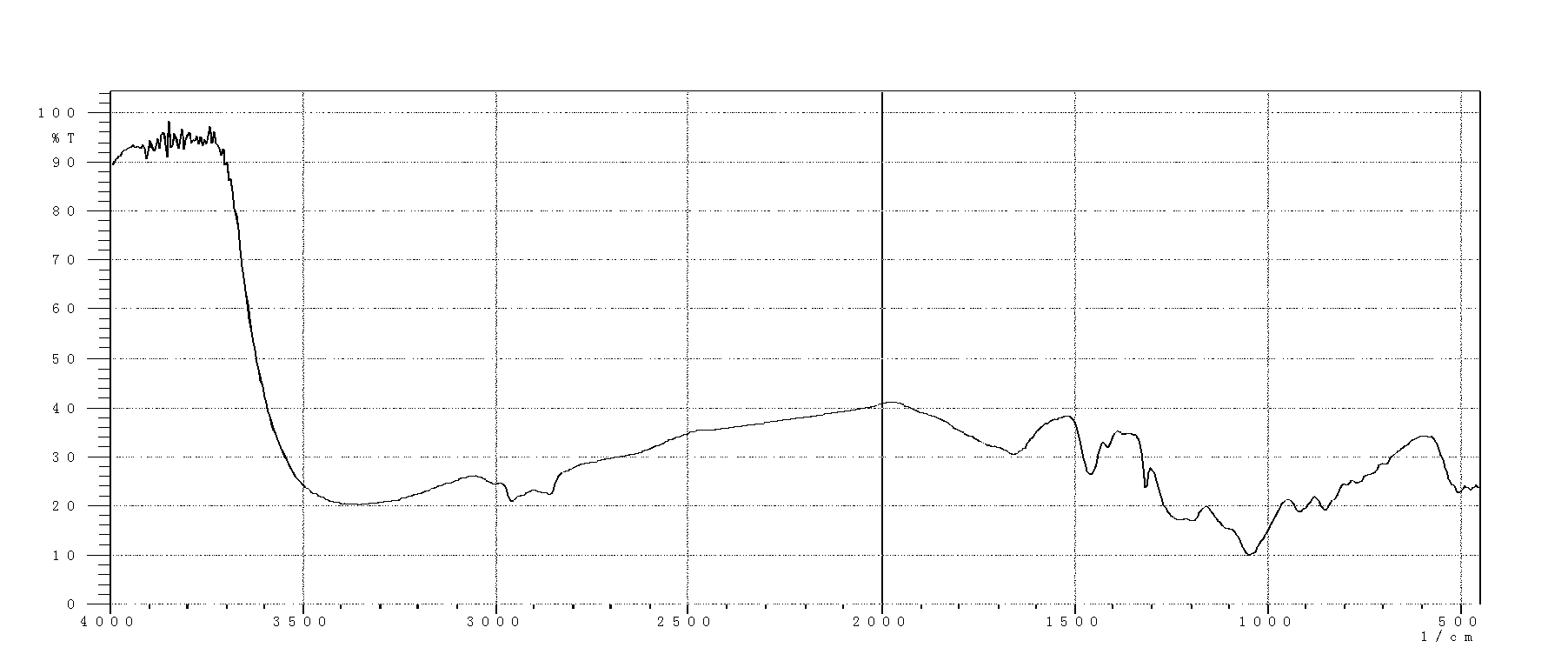

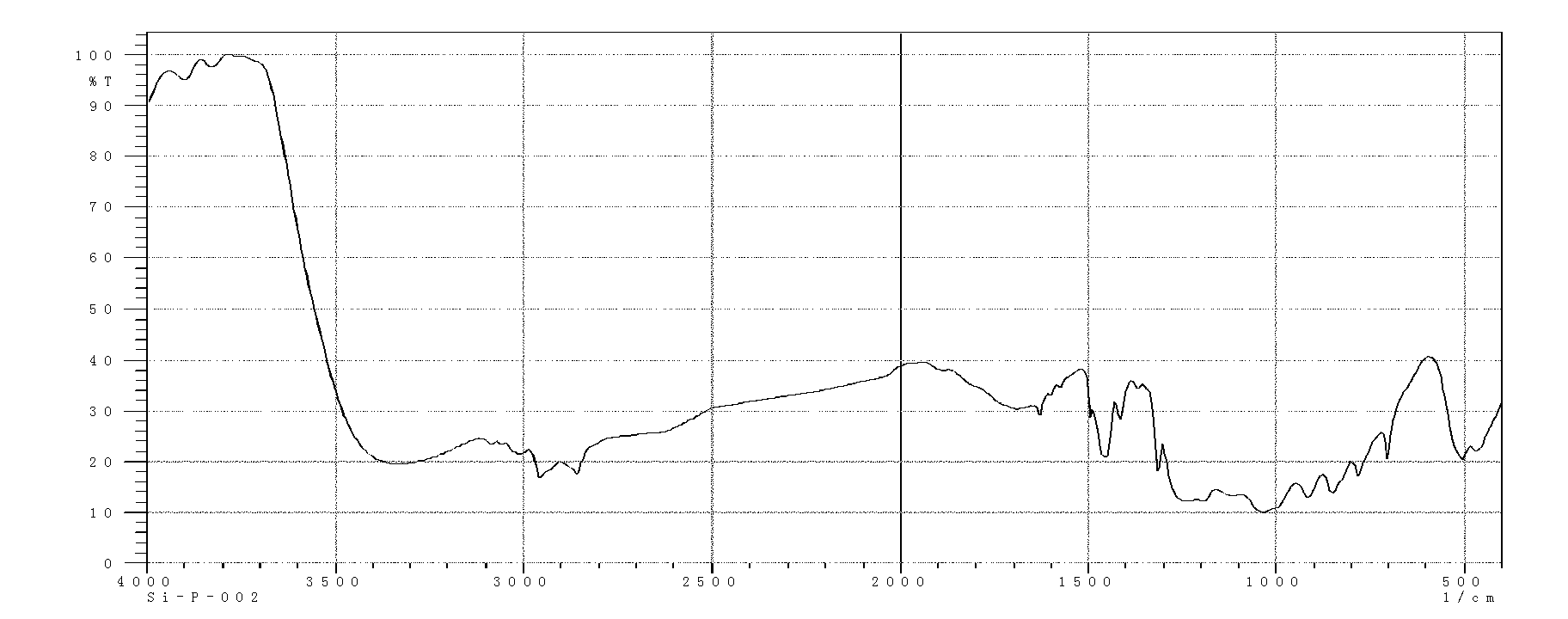

Image

Examples

Embodiment 1

[0049] In a 2-liter four-necked round-bottomed flask equipped with a stirrer, a thermometer, a dropping funnel and a condenser tube, add 300 g (2.42 mol) of dimethyl methylphosphonate, heat to 60-65 ° C, and then add pentoxide 300 g (2.12 mol) of diphosphorus, heat up to 115-120° C. after the complete dissolution of the diphosphorus pentoxide, and keep it warm for 1 hour. Cool the reactant to 60-65°C, add 24 grams (0.52mol) of ethanol, and add 3-glycidyl etheroxypropyltrimethoxysilane (SCA-403, Zhangjiagang Guotai Huarong Chemical New Co., Ltd. Material Co., Ltd.) 572 g (2.42 mol), and finally add 0.6 g of stannous octoate, and react at 100-105° C. for 1 hour to obtain a colorless transparent viscous liquid. Distill the viscous liquid at about 100°C and vacuum degree of -0.095~-0.098Mpa to remove unreacted raw materials, and the transparent viscous liquid left at the bottom of the bottle is the refined product of the flame retardant. After measurement, the viscosity average m...

Embodiment 2

[0057] In a 2-liter four-necked round-bottomed flask equipped with a stirrer, a thermometer, a dropping funnel and a condenser tube, add 431 grams (2.42 mol) of allyl phosphonic acid diethyl ester, heat to 30-35 ° C, and then add 150 grams (1.06 mol) of phosphorus pentoxide, after the phosphorus pentoxide is completely dissolved, heat up to 75-80°C, and keep it warm for 8 hours. Cool the reactant to 60-65°C, add 24 grams (0.52mol) of ethanol, and add 3-glycidyl etheroxypropyl triethoxysilane (SCA-413, Zhangjiagang Guotai Huarong Chemical Industry Co., Ltd. New Materials Co., Ltd.) 320 g (1.15 mol), and finally add 4.2 g of sodium ethylate, and keep warm at 70-75 ° C for 6 hours to obtain a colorless transparent viscous liquid. Distill the unreacted raw materials under reduced pressure at about 100°C and vacuum degree of -0.095~-0.098Mpa, and the transparent viscous liquid left at the bottom of the bottle is the prepared flame retardant Refined products. After measurement, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com