Bioactive coating of metal implant and preparation method thereof

A bioactive, implant technology, applied in the field of metal implant bioactive coatings and its preparation, can solve the problems of low concentration of conductive ions, less calcium and phosphorus, and deterioration of active coatings, and achieve simple preparation process, Good biological activity and high oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

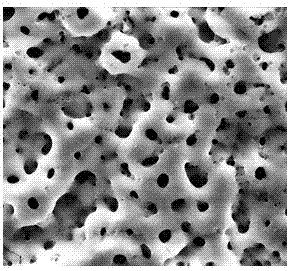

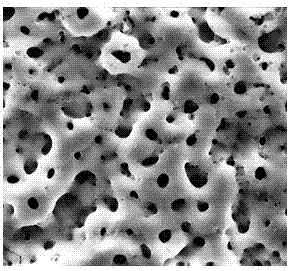

Image

Examples

Embodiment 1

[0035] A bioactive coating of a medical metal implant, which is prepared by the following method:

[0036] (1) Preparation of micro-arc oxidation treatment solution

[0037] Calculated per liter of micro-arc oxidation treatment solution, the amount of solute added is: 6g of sodium silicate, 6g of calcium acetate, 4g of sodium dihydrogen phosphate, 4g of potassium hydroxide, 4g of sodium fluoride, and the solvent is deionized water;

[0038] Prepare 10L of the above-mentioned micro-arc oxidation treatment solution, that is, add sodium silicate, sodium dihydrogen phosphate, potassium hydroxide, sodium fluoride, and calcium acetate into deionized water in sequence, stir and mix evenly, and adjust the pH value to 11 with sodium hydroxide can;

[0039] (2) Pretreatment of medical metal implants

[0040]The medical metal implant, that is, the Ti-6Al-4V plate of 10×10×2 mm, was soaked in 10% NaOH aqueous solution at 70 °C for 5 minutes to remove oil, and it was treated with 5% HF a...

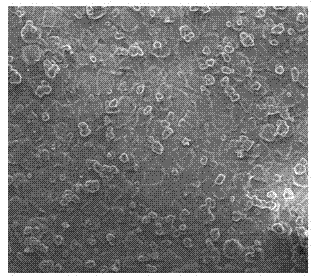

Embodiment 2

[0044] A bioactive coating of a medical metal implant, which is prepared by the following method:

[0045] (1) Preparation of micro-arc oxidation treatment solution

[0046] Calculated per liter of micro-arc oxidation treatment solution, the amount of solute added is: 3g sodium silicate, 3g calcium acetate, 2g sodium dihydrogen phosphate, 2g potassium hydroxide, 2g sodium fluoride, and the solvent is deionized water;

[0047] Prepare 10L of the above-mentioned micro-arc oxidation treatment solution, that is, add sodium silicate, sodium dihydrogen phosphate, potassium hydroxide, sodium fluoride, and calcium acetate into deionized water in sequence, stir and mix evenly, and adjust the pH value to 12 with sodium hydroxide can;

[0048] (2) Pretreatment of medical metal implants

[0049] The medical metal implant, that is, the Ti-6Al-4V plate of 10×10×2 mm, was soaked in 10% NaOH aqueous solution at 70 °C for 5 minutes to remove oil, and it was treated with 5% HF acid and 5% HNO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com