Preparation method for constructing collagen-based bio-macromolecular/hydroxyapatite microsphere composite bracket material

A technology of biological macromolecules and hydroxyapatite, which is applied in the field of preparing collagen-based biological macromolecules/hydroxyapatite microsphere composite scaffold materials, can solve the problems of synthesizing hydroxyapatite particles and the like, and achieves a novel preparation method. And simple, mild preparation conditions, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

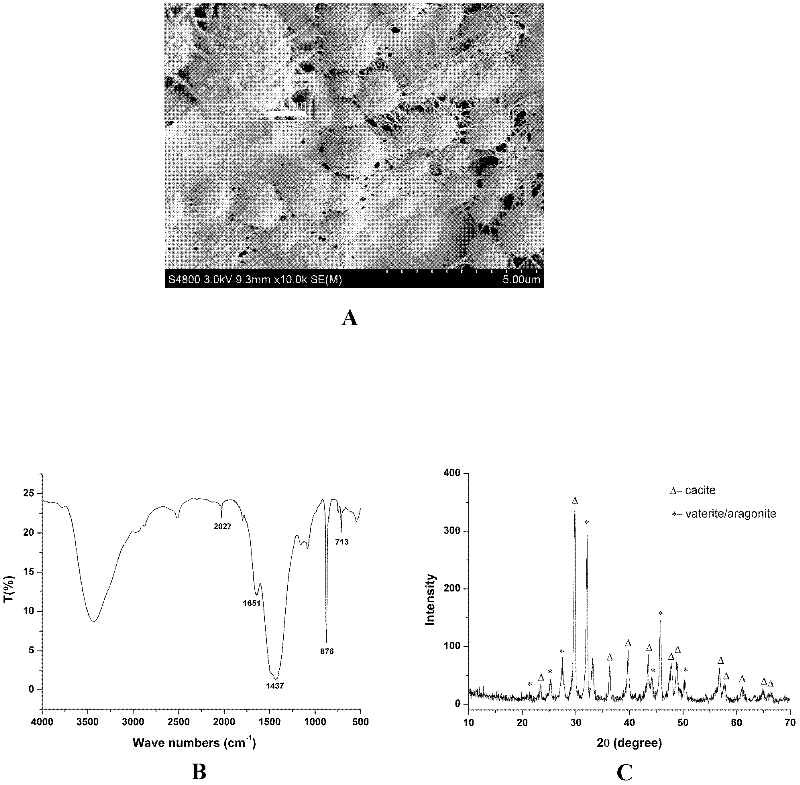

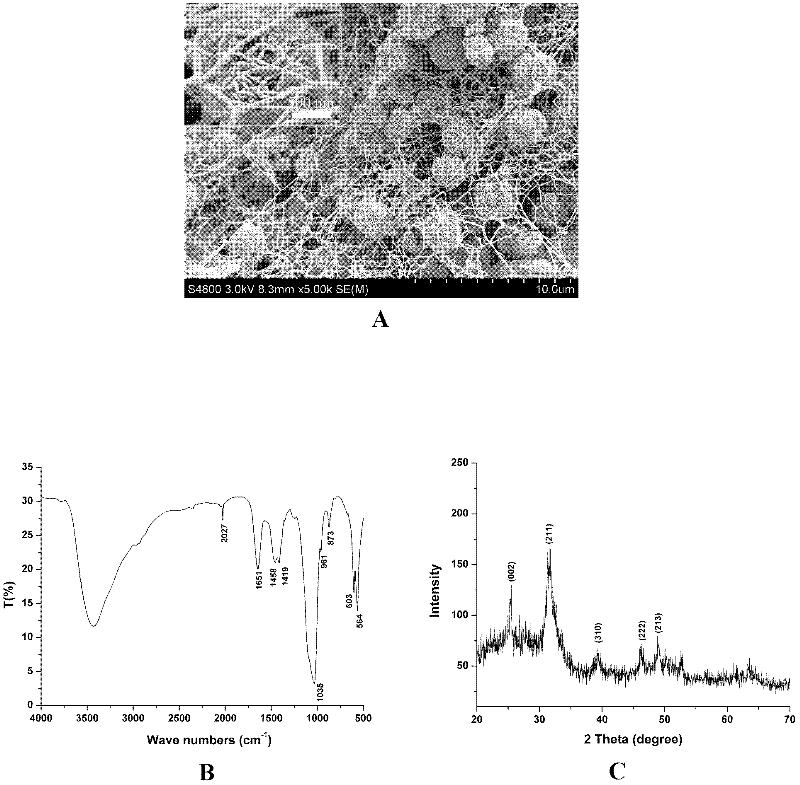

[0052] The collagen solution was prepared with hydrochloric acid of pH 3, and the collagen concentration was 8 mg / mL. Add calcium nitrate aqueous solution to the collagen solution under stirring conditions, the final concentration of calcium ions is 0.1mol / L, and then quickly mix with sodium bicarbonate aqueous solution with a concentration of 0.1mol / L, and stir for 2 minutes. The above operating temperature was maintained at 4°C. After the reaction mixture was centrifuged at low speed, it was transferred to a beaker and kept in a water bath at 25°C for 16 hours to obtain collagen / CaCO 3 Microsphere composite gel, its scanning electron microscope photo is detailed in figure 1 A; its chemical composition and phase crystal analysis are detailed in figure 1 B and figure 1 c. Collagen / CaCO 3 The microsphere composite gel was immersed in a disodium hydrogen phosphate aqueous solution with a concentration of 0.2mol / L. The temperature of the solution was controlled by a water ba...

Embodiment 2

[0054] The collagen solution was prepared with hydrochloric acid of pH 2, and the collagen concentration was 6 mg / mL. Add calcium chloride aqueous solution to the collagen solution under stirring conditions, the final concentration of calcium ions is 0.03mol / L, and then quickly mix with sodium carbonate aqueous solution with a concentration of 0.03mol / L, and stir for 0.5min. The above operating temperature was maintained at 4°C. After the reaction mixture was centrifuged at low speed, it was transferred to a beaker and kept in a water bath at 28°C for 14 hours to obtain collagen / CaCO 3 The microsphere composite gel is immersed in a disodium hydrogen phosphate aqueous solution with a concentration of 0.4mol / L, the temperature of the solution is controlled by a water bath, and the temperature is kept at 35°C for 7 days, and the phosphate aqueous solution is replaced once a day. Afterwards, the composite gel was soaked in deionized water for 5 times to remove the residual salt, ...

Embodiment 3

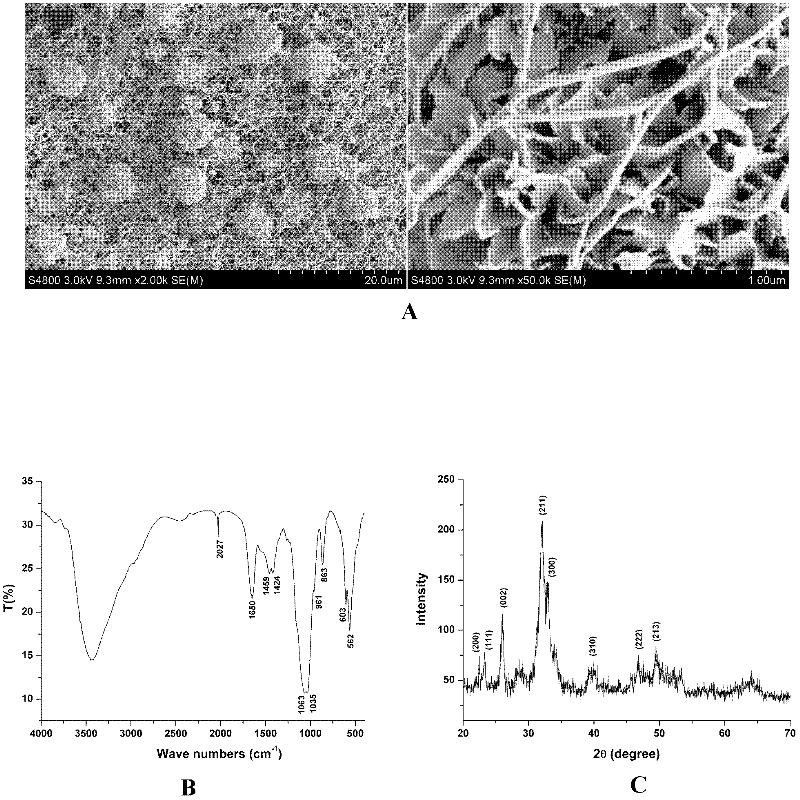

[0056] The collagen solution was prepared with hydrochloric acid of pH 3.5, and the collagen concentration was 3 mg / mL. Add calcium chloride aqueous solution to the collagen solution under stirring conditions, the final concentration of calcium ions is 0.06mol / L, and then quickly mix with ammonium bicarbonate aqueous solution with a concentration of 0.06mol / L, and stir for 5 minutes. The above operating temperature was maintained at 4°C. After the reaction mixture was centrifuged at low speed, it was transferred to a beaker and kept in a water bath at 25°C for 12 hours to obtain collagen / CaCO 3 The microsphere composite gel is immersed in a diammonium hydrogen phosphate aqueous solution with a concentration of 0.5mol / L. The temperature of the solution is controlled by a water bath and kept at 32°C for 2 days, and the phosphate aqueous solution is replaced every 2 days. Afterwards, the composite gel was soaked in deionized water for 5 times to remove residual salt therein, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com