PLGA-PEG-PLGA inlaid mineralized collagen coating and its preparation method

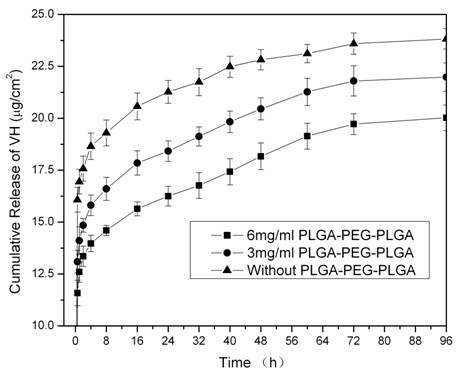

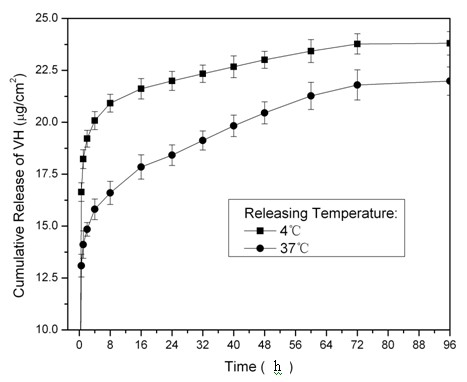

A PLGA-PEG-PLGA, mineralized collagen technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problem of undiscovered composite coatings, and achieve high-efficiency loading and slow release. , wide application prospects, the effect of improving sustained release behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation method of the mineralized collagen coating inlaid with the PLGA-PEG-PLGA copolymer involved in the present invention comprises the following steps:

[0016] 1. Surface pretreatment of the metal substrate: including cleaning the surface of the metal substrate, controlling the roughness, and treating the oxide layer, etc.

[0017] 2. Prepare the electrolyte, and use electrochemical deposition to obtain a porous mineralized collagen coating on the surface of the metal implant.

[0018] In the present invention, the prepared electrolyte contains Ca 2+ 、H 2 PO 4 - 、H 2 o 2 and collagen, their concentrations are 4~8mmol / L, 8~16 mmol / L, 15~20 mmol / L and 0.1~0.6g / L respectively, and the pH of the electrolyte is 4.3~4.6 (use 0.25~1mol / L adjusted by NaOH solution). The metal substrate is the cathode, the platinum electrode is the anode, the electrolyte is placed in a water bath at a temperature of 37 °C, the distance between the cathode and the anode is 1-2...

Embodiment 1

[0027] Dissolve collagen in 0.005mol / L acetic acid, stir to form a solution with a collagen concentration of 0.5g / L, add Ca(NO 3 ) 2 ·6H 2 O and NH 4 h 2 PO 4 Dissolve in deionized water, mix with collagen solution and a small amount of hydrogen peroxide to form calcium, phosphorus, H 2 o 2, and collagen concentrations of 8 mmol / L, 16 mmol / L, 15 mmol / L, and 0.6 g / L electrolytes, and the pH of the electrolyte was adjusted to 4.3 with NaOH solution. The titanium plate after surface pretreatment was used as the cathode, the platinum electrode was used as the anode, and the distance between the cathode and the anode was 1cm. Take 15ml of the electrolyte and place it in a water bath at 37°C, using a constant voltage deposition mode with a voltage of 2.5V. After 30 minutes of deposition, the titanium substrate was taken out, washed with deionized water, and then air-dried naturally to obtain a porous mineralized collagen gradient coating. PLGA-PEG-PLGA was added to deionized ...

Embodiment 2

[0029] Dissolve collagen in 0.005mol / L acetic acid, stir to form a solution with a collagen concentration of 0.5g / L, add Ca(NO 3 ) 2 ·6H 2 O and NaH 2 PO 4 Dissolve in deionized water, mix with collagen solution and a small amount of hydrogen peroxide to form calcium, phosphorus, H 2 o 2 , collagen concentrations of 4 mmol / L, 8 mmol / L, 20 mmol / L, and 0.1 g / L electrolytes, and adjust the pH of the electrolyte to 4.6 with NaOH solution. The titanium plate after surface pretreatment was used as the cathode, and the platinum electrode was used as the anode. The distance between the cathode and the anode was 2cm. Take 15ml of electrolyte and place it in a water bath at 37°C. The constant voltage deposition mode was used with a voltage of 2.5V. After 45 minutes of deposition, the titanium substrate was taken out, washed with deionized water, and then air-dried naturally to obtain a porous mineralized collagen gradient coating. PLGA-PEG-PLGA was added to deionized water to prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com