Heatproof anticorrosion coating with ion barrier ability and selectivity and preparation method thereof

An anti-corrosion coating and selective technology, which is applied in the anti-corrosion treatment of metal materials, heat-resistant anti-corrosion coating and its preparation field, can solve the problems of easy defects and large volume, and achieve simple preparation process, good application performance, prevent penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062]In the present embodiment 1, be to make the anticorrosion coating of the present invention outside the steel pipeline, and concrete process comprises:

[0063] Modification of hydrotalcite: take 10gMg-Al-LDH, dissolve in 300ml boiling (except CO 2 ) in the liquid (deionized water: ethanol = 1: 1, volume percentage), then transferred to a three-necked flask; under magnetic stirring at 80°C in a water bath, add 100ml of 0.1M sodium metavanadate solution, and stir at reflux temperature React for 2 hours, then adjust with 0.1M sodium hydroxide solution to make the solution pH=8.4, then allow the reaction product to cool naturally at room temperature, centrifuge, wash 3 times with ethanol and water mixture (volume percentage 1: 1), 80 ° C Vacuum dried for 24 hours and ground through a 200-mesh sieve. The Zeta potential of the obtained powder was measured to be 12 mV.

[0064] Add the modified hydrotalcite powder equivalent to 3% resin mass percentage to the mixture of bisph...

Embodiment 2

[0074] The coating preparation method of this embodiment 2 is the same as that of embodiment 1, except that the electrolyte solution is changed to 5% hydrochloric acid solution at 90° C., and the rest of the test conditions are the same.

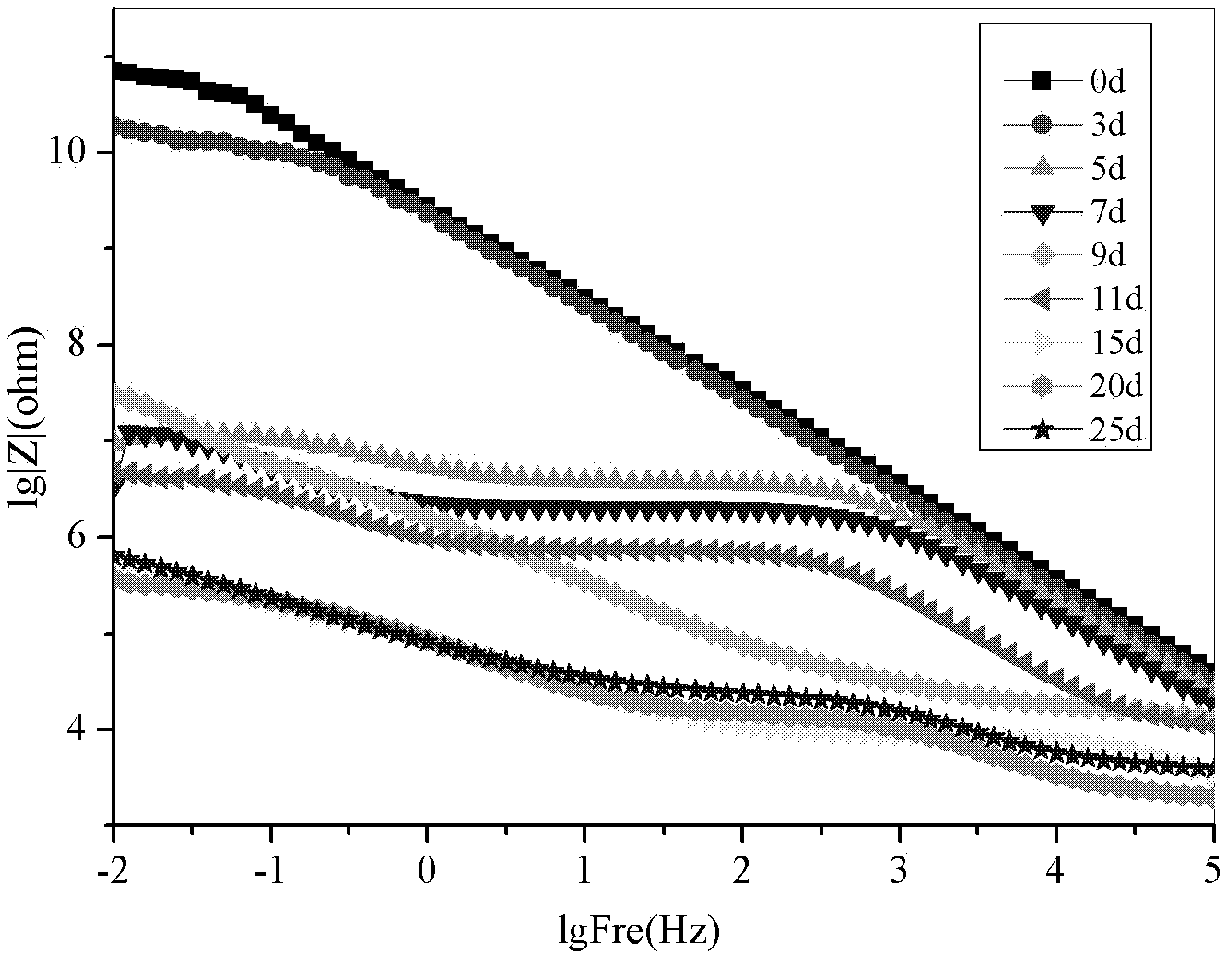

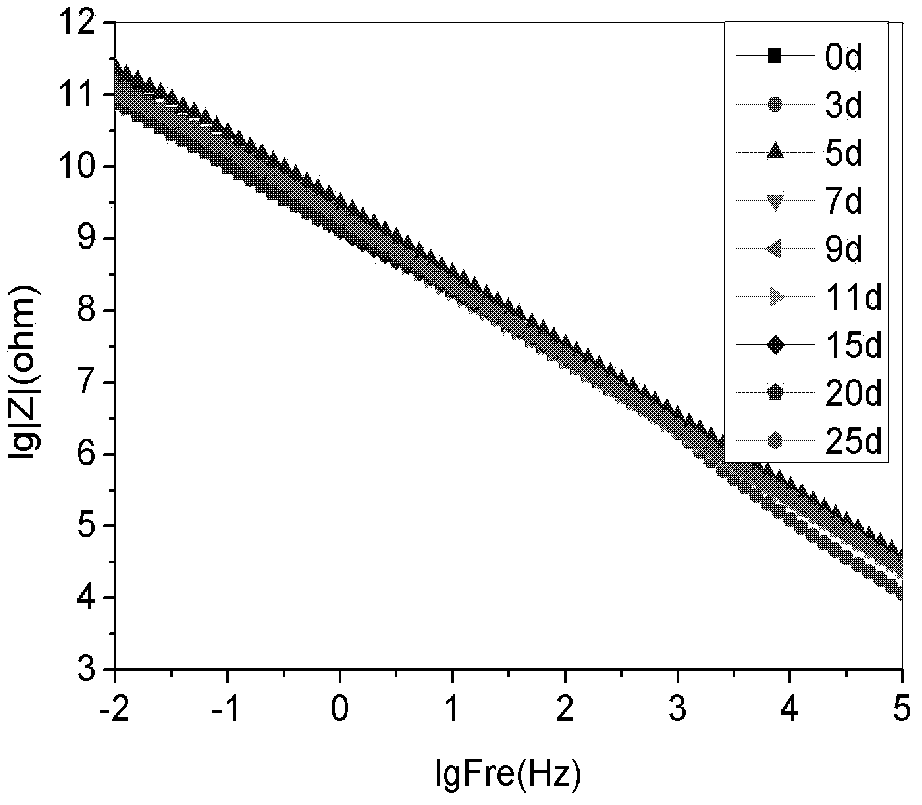

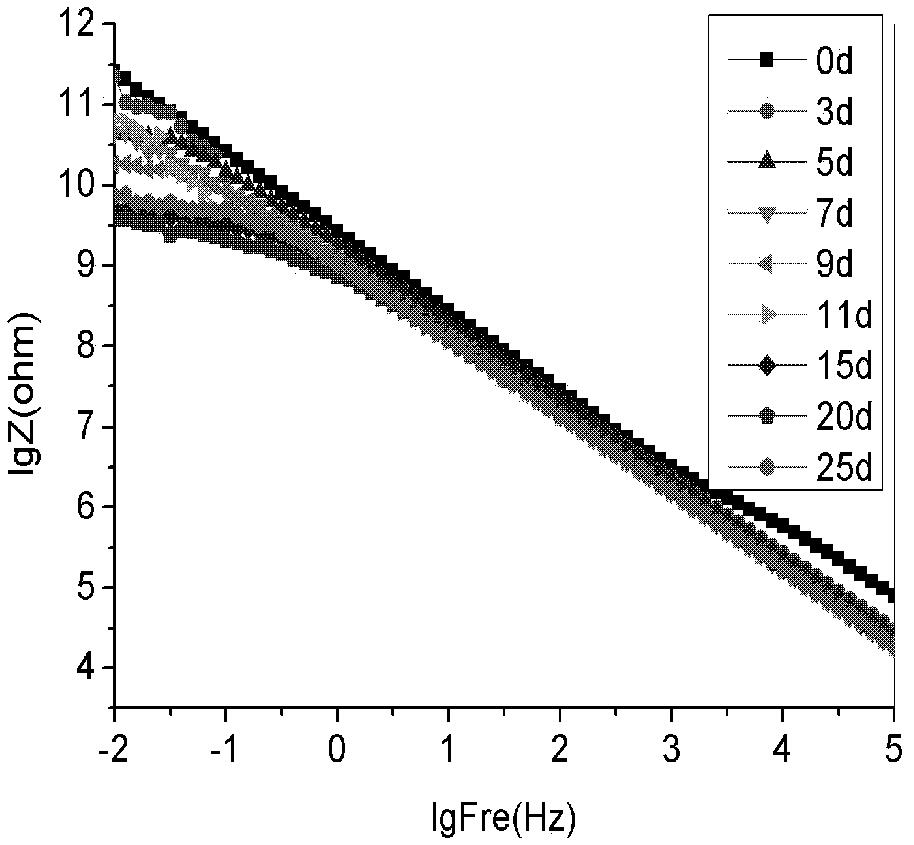

[0075] For test results see Figure 7 , Figure 8a , Figure 8b and Figure 9 . Figure 7 Impedance-frequency relationship showing different immersion times for common epoxy coatings; Figure 8a and Figure 8b The impedance-frequency relationship of different immersion times for a single cation-selective coating and anion-selective coating; Figure 9 It is the impedance-frequency relationship of the anodic and anodic ion-selective coatings of the present invention at different immersion times. It can be found that the resistance value of ordinary epoxy coatings decreases rapidly with the extension of time, and the anti-corrosion effect of a single ion-selective coating is better than that of ordinary epoxy coatings, and the anti-corros...

Embodiment 3

[0077] The preparation method of the coating in Example 3 is the same as in Example 1, and the anti-corrosion performance of the coating under simulated working conditions was investigated in a high temperature and autoclave. The test conditions are: the temperature in the kettle is 135°C, the corrosion medium is 5% potassium chloride solution, the total pressure in the kettle is 2MPa, H 2 S gas partial pressure 0.4MPa, CO 2 The partial pressure is 1.6MPa, the oxygen is removed by high-purity nitrogen, and the test time is 5 days.

[0078] SEM and energy spectrum were used to observe the morphology and composition of corrosion products. For the test results, see Figures 10a-10d . The SEM image in the figure shows that the lower layer is the side close to the metal, and the upper layer is the side directly in contact with the corrosive medium. Severe swelling occurs after the pure epoxy coating is soaked, and the coating fails; there are only potassium ions and no chloride ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com