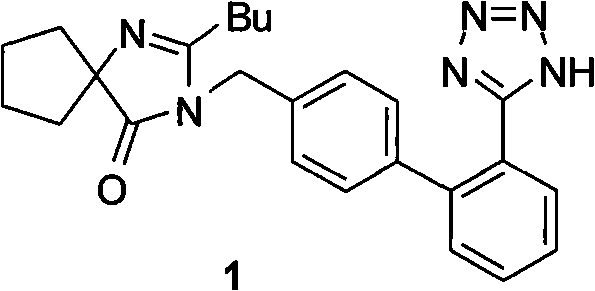

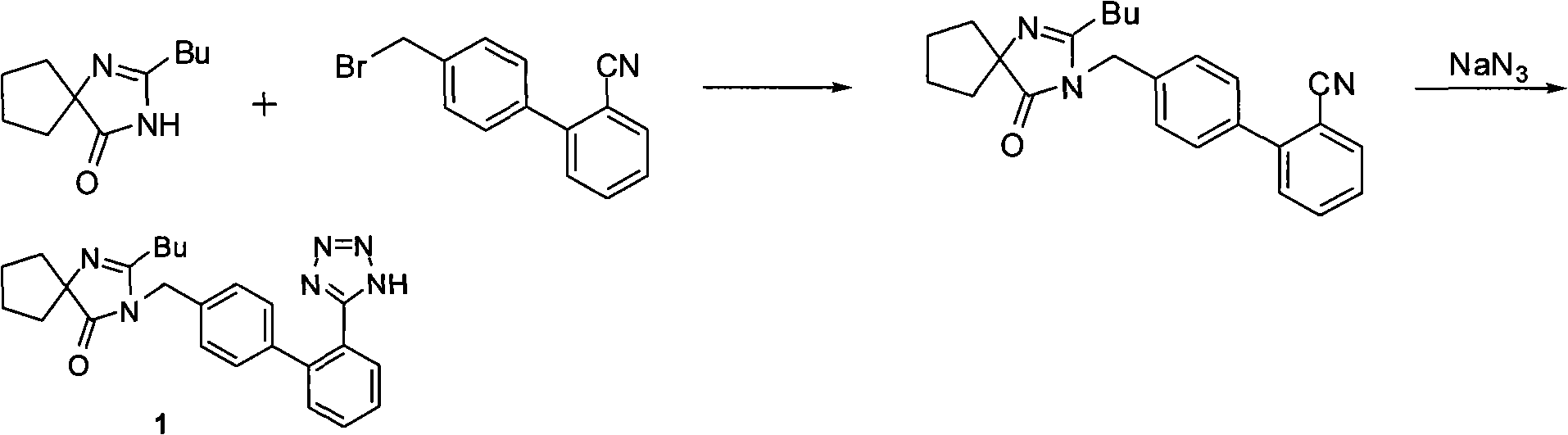

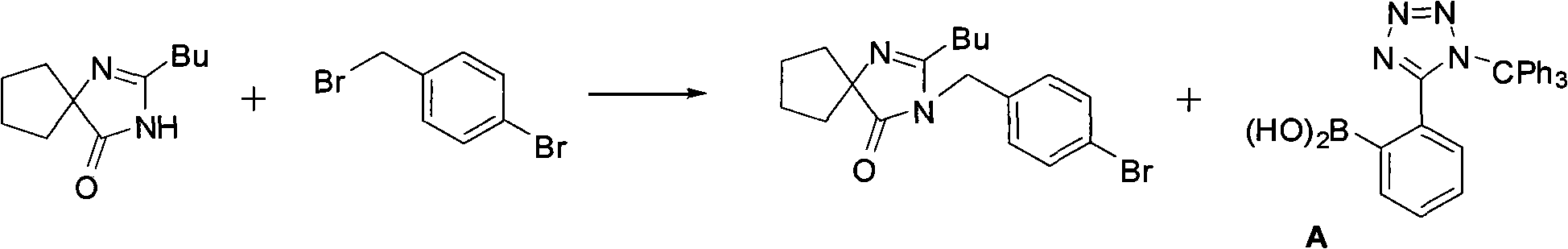

Method for synthesizing irbesartan and intermediate thereof

A technology for intermediates and compounds, applied in the field of pharmaceutical preparation, can solve the problems of safety risks, high cost, complicated preparation process, etc., and achieve the effects of ensuring safety, saving raw material costs, and convenient synthesis methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1: Preparation of formula 3 compound: 1-aminocyclopentanitrile oxalate

[0054] 20g (0.41mol) of sodium cyanide was dissolved in 40mL of water, 60mL of aqueous solution of 23g (0.43mol) of ammonium chloride was added, 35mL of 20% ammonia water and 40mL of methanol solution of 30g (0.36mol) of cyclopentanone were stirred at room temperature for 1.5 hours, and the temperature was raised Stir at 60°C for another 45 minutes, stop heating, and continue stirring for 45 minutes. Cool down to room temperature, extract with 80mL×6 dichloromethane, dry the organic phase with anhydrous magnesium sulfate, filter, concentrate the filtrate, dissolve 41g of the remaining oil in 100mL of acetone, add 25g (0.28mol) of oxalic acid in 200mL of acetone solution while stirring, The solid was precipitated, filtered, the filter cake was rinsed with acetone, and dried to obtain 50.0 g of white solid, yield 70.0%, Mp 220°C.

Embodiment 2

[0055] Example 2: Preparation of formula 4 compound: 1-aminocyclopentamide

[0056] 50.0g (0.25mol) of compound (3) was slowly added to 75mL of concentrated sulfuric acid, stirred, bubbles were generated, and the temperature rose to 90°C. After adding, heat and stir for 1 hour, cool down to 35°C, pour into ice water containing 300mL concentrated ammonia water, extract 6 times with chloroform containing 10% methanol, combine organic phases, dry over anhydrous magnesium sulfate, filter, and evaporate the filtrate under reduced pressure solvent to obtain 35.0 g of white solid, Mp 94-95°C.

Embodiment 3

[0057] Example 3: Preparation of compound of formula 5: 2-butyl-1,3-diazaspiro[4.4]non-1-en-4-one hydrochloride 30.0g (0.23mol) compound (4), 33mL (0.24mol) Add triethylamine to 500mL tetrahydrofuran, add dropwise 50mL of a tetrahydrofuran solution of 30g (0.25mol) valeryl chloride, stir for 0.5 hours, add 70mL water, 150mL methanol and 70g potassium hydroxide, reflux for 5 hours, and add 90g chloride Ammonium, stirred for 0.5 hours, concentrated under reduced pressure, added 40 mL of water to the residue, extracted with 100 mL of ethyl acetate x 3, combined the organic layers, added anhydrous magnesium sulfate to dry and filtered, added 20 mL of methanol to the filtrate, cooled to below 20 °C, HCI gas was introduced to pH=1-2, cooled to 0-5°C, stirred for 1 hour, and filtered to obtain 40.2 g of white powdery solid, yield 88.4%, Mp 259-261°C.

[0058] IR (KBr, cm -1 ): 2962.1, 2787.6, 2631.8, 1777.9 (C=O), 1641.4, 1517.4, 1061.2. 1 H-NMR (DMSO-d 6 , 400MHz) δ: 13.648 (br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com