Synthetic method of N-2-hydroxypropyl trimethyl ammonium chloride chitosan and preparation method of Newcastle disease attenuated live vaccine-loaded nanoparticles of N-2-hydroxypropyl trimethyl ammonium chloride chitosan

A technology of hydroxypropyltrimethylammonium chloride and epoxypropyltrimethylammonium chloride, which is applied in the field of synthesis and preparation of vaccine-loaded nanoparticles, can solve the problems of poor water solubility and achieve high encapsulation efficiency , simple preparation process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

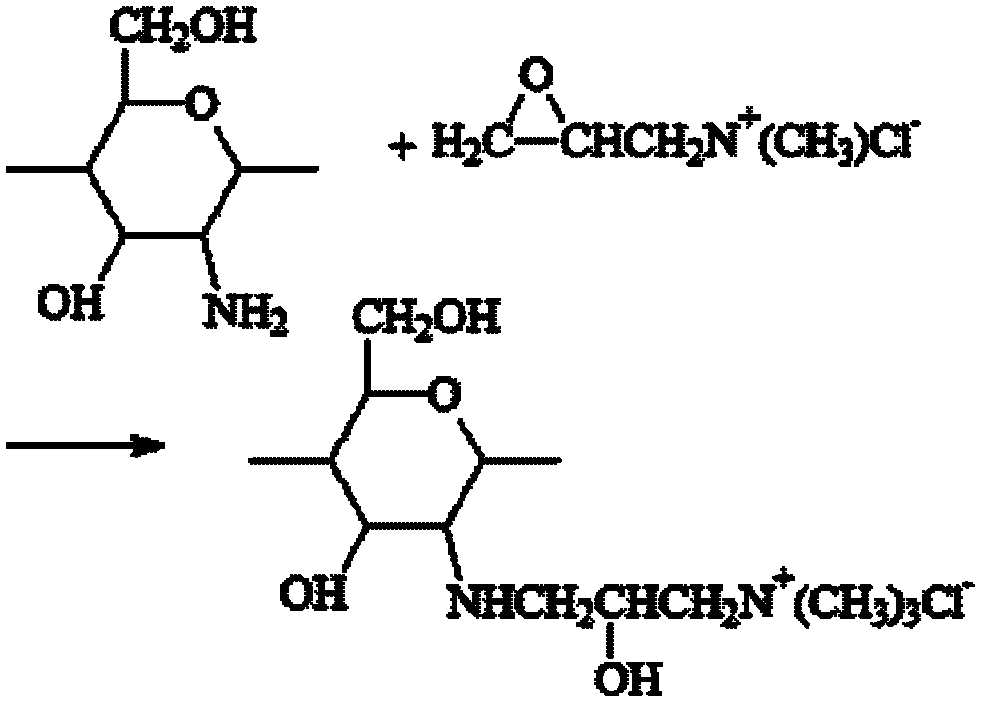

[0024] Specific embodiment one: the synthetic method of present embodiment N-2-hydroxypropyltrimethylammonium chloride chitosan is realized according to the following steps:

[0025]1. Disperse 50g of chitosan with a deacetylation degree of 85% in 200mL NaOH isobutanol solution, reflux and stir at 90-120°C for 1 hour, remove the supernatant and wash the precipitate with deionized water until neutral. Then disperse in 200mL NaOH isobutanol solution, continue to reflux and stir for 1.5 to 8 hours, remove the supernatant, and wash the precipitate with deionized water to neutrality to obtain deacetylated chitosan;

[0026] Two, the chitosan of 2~3g deacetylation process is dissolved in 100~150mL volume concentration and is 1~3% acetic acid solution, stirring and dissolving, vacuum suction filtration, filter out insoluble matter, obtain chitosan solution, then in 500 Add NaOH solution with a concentration of 0.1-2mol / L drop by drop under the stirring condition of ~1000r / min, adjust...

Embodiment 1

[0034] The synthetic method of N-2-hydroxypropyltrimethylammonium chloride chitosan is realized in the following steps:

[0035] 1. Disperse 50g of chitosan with a deacetylation degree of 85% in 200mL NaOH isobutanol solution, reflux and stir at 110°C for 1 hour, remove the supernatant and wash the precipitate with deionized water until neutral, then disperse In the isobutanol solution of 200mL NaOH, continue to reflux and stir for 1.5h, remove the supernatant and wash the precipitate with deionized water to neutrality to obtain deacetylated chitosan;

[0036] Two, the chitosan of 3g deacetylation process is dissolved in 150mL volume concentration and is 2% acetic acid solution, stirring and dissolving, vacuum suction filtration, filter off insoluble matter, obtain chitosan solution, then gradually under 750r / min stirring condition Add dropwise NaOH solution with a concentration of 0.1mol / L, adjust the pH value of the chitosan solution to 8.8 and white precipitates will separa...

specific Embodiment approach 2

[0042] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the molecular weight of chitosan in step one is 71.3. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com