High-density production process for forage bacillus subtilis, microbial inoculum prepared by using forage bacillus subtilis and application of microbial inoculum

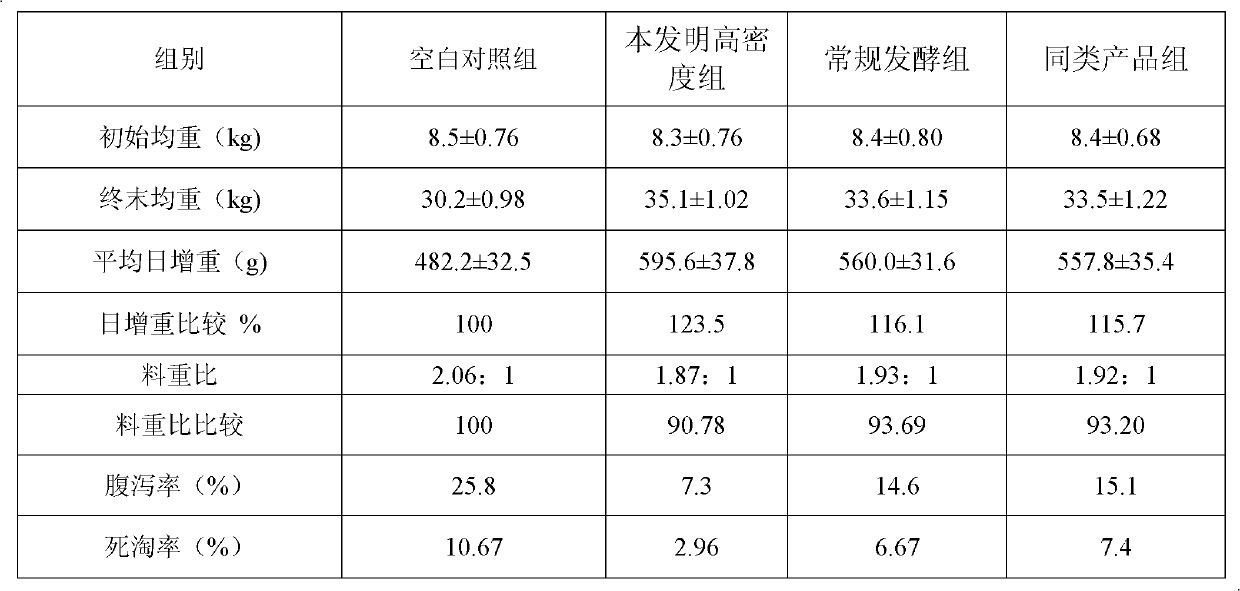

A Bacillus subtilis and production process technology, which is applied in the field of prepared bacterial agents, can solve the problems that the high-density production process of Bacillus subtilis has not yet been reported, and achieve the effects of improving animal production performance, reducing the death rate, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1, Bacillus subtilis ACCC10619 slope activation of the present invention (substratum beef extract 0.3~0.5%, sodium chloride 0.5~1.0%, peptone 0.5~1.0%, add water to 100%; pH 6.8~7.5, place 30~34 Cultivate in a biochemical incubator for 18-24 hours), inoculate an inoculation loop into 100ml seed liquid, and carry out seed shake flask cultivation; temperature is 30°C, shaker rotation speed is 220r / min, and time is 18-24 hours.

[0029] The seed shake flask medium is 0.3% of beef extract, 0.5% of sodium chloride, 1.0% of peptone, added water to 100%, pH 7.0.

[0030] 2. The strain activated on the slant was subjected to seed shake flask culture, and then shake flask fermentation culture; the shake flask fermentation culture conditions were fermentation temperature 30° C., pH value 7.0, shaking table rotation speed 220 rpm; culture for 18 hours. The fermentation medium is composed of the following components: glucose 0.5%, starch 0.3%, bean cake powder 1.5%, 3.08% manganese s...

Embodiment 2

[0035] 1, Bacillus subtilis ACCC10619 slope activation of the present invention (substratum beef extract 0.3~0.5%, sodium chloride 0.5~1.0%, peptone 0.5~1.0%, add water to 100%; pH 6.8~7.5, place 30~34 Cultivate in a biochemical incubator for 18-24 hours), inoculate an inoculation loop into 100ml seed liquid, and carry out seed shake flask cultivation; temperature is 30°C, shaker rotation speed is 220r / min, and time is 18-24 hours.

[0036] The culture medium of the seed shake flask is beef extract 0.5%, sodium chloride 0.5%, peptone 1.0%, water is added to 100%, pH 7.0.

[0037] 2. The strain activated on the slant was subjected to seed shake flask culture, and then shake flask fermentation culture; the shake flask fermentation culture conditions were fermentation temperature 28°C, pH value 6.8, shaking table rotation speed 200rpm; culture 20h. The fermentation medium is composed of the following components: glucose 0.6%, starch 0.2%, bean cake powder 1%, 2.58% manganese sulf...

Embodiment 3

[0041] 1, Bacillus subtilis ACCC10619 slope activation of the present invention (substratum beef extract 0.3~0.5%, sodium chloride 0.5~1.0%, peptone 0.5~1.0%, add water to 100%; pH 6.8~7.5, place 30~34 Cultivate in a biochemical incubator for 18-24 hours), inoculate an inoculation loop into 100ml seed liquid, and carry out seed shake flask cultivation; temperature is 30°C, shaker rotation speed is 220r / min, and time is 18-24 hours.

[0042] The seed shake flask medium is 0.3% of beef extract, 0.5% of sodium chloride, 1.0% of peptone, added water to 100%, pH 7.0.

[0043] 2. The strain activated on the slant was subjected to seed shake flask culture, and then shake flask fermentation culture; the shake flask fermentation culture conditions were fermentation temperature 34°C, pH value 7.2, shaking table rotation speed 250rpm; culture time 18h. The fermentation medium is composed of the following components: glucose 0.75%, starch 0.4%, bean cake powder 2%, 3.88% manganese sulfate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com