Fluorescent optical fiber and production method thereof, and white light floodlight made from fluorescent optical fiber

A fluorescent optical fiber and lighting technology, which is applied to cladding optical fibers, lighting devices, optical waveguides and light guides, etc., can solve the problems of small light-emitting angle, different light, and high heat dissipation cost, so as to reduce heat dissipation cost, large light-emitting angle, and soft light. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

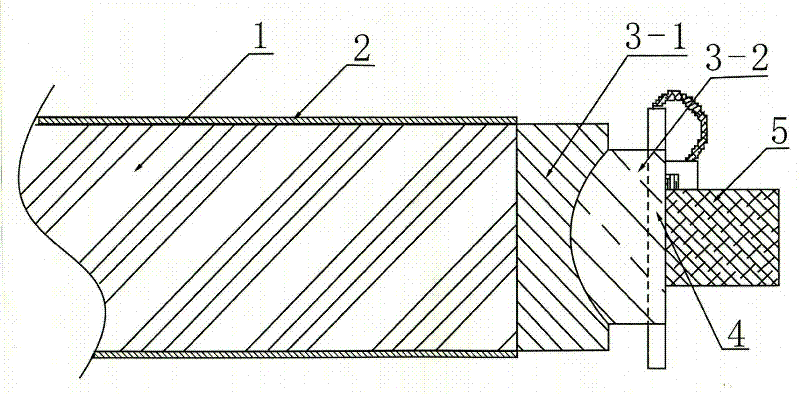

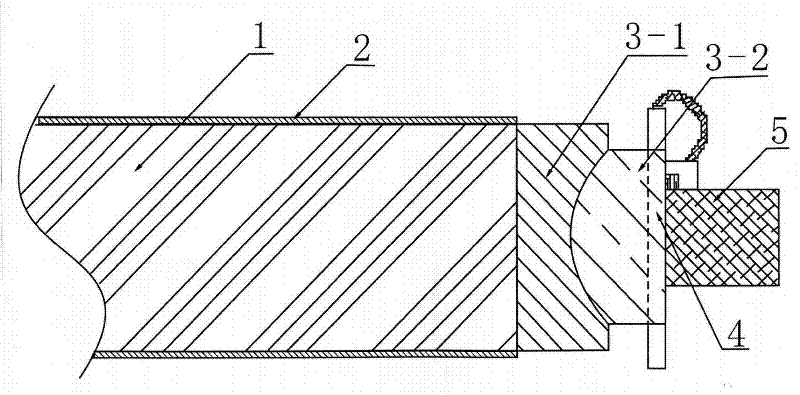

[0030] see figure 1 As shown, a fluorescent optical fiber has a phosphor layer 2 deposited on the surface of the optical fiber 1. The thickness of the phosphor layer 2 is 0.00001-0.001 mm. The optical fiber 1 can be a quartz optical fiber, or a plastic optical fiber or a plastic light guide column. . The phosphor powder of the phosphor powder layer 2 can adopt yellow phosphor powder or red phosphor powder or green phosphor powder or blue phosphor powder and mixture thereof, no matter adopt single-color phosphor powder or multi-color phosphor powder mixture, its color should be luminous with diode Only when the luminous colors of the modules match, can they emit white light directly.

Embodiment 2

[0032] One of the methods of depositing a layer of phosphor layer 2 on the surface of the optical fiber is:

[0033] (1) First clean the surface of the optical fiber with pure water to remove grease and other impurities, and then bake to remove water;

[0034] (2) Treat the optical fiber with mild plasma to increase the adhesion of the phosphor on the surface of the optical fiber. The treatment conditions are: vacuum degree 0.001-0.000001 mm Hg, time 1-10 minutes, and the protective gas is argon with a purity of 99.999%. gas;

[0035] (3) Put the optical fiber treated with mild plasma surface into a low-temperature horizontal magnetron sputtering machine for vacuum sputtering, the target material is phosphor powder, and the sputtering conditions are: vacuum degree is 0.001-0.000001 mm Hg, and the time is 1 - 10 minutes, use argon gas with a purity of 99.999% as the protective gas, and deposit phosphor molecules on the surface of the optical fiber by means of momentum transfer...

Embodiment 3

[0037] The second method of depositing a layer of phosphor layer 2 on the surface of the optical fiber is:

[0038] (1) Clean the optical fiber and bake to remove water;

[0039] (2) Treat the optical fiber with mild plasma to increase the adhesion of the phosphor on the surface of the optical fiber. The treatment conditions are: vacuum degree 0.001-0.000001 mm Hg, time 1-10 minutes, and the protective gas is argon with a purity of 99.999%. gas;

[0040] (3) Use a sublimation machine to further purify the phosphor powder at a temperature of 300-500°C for 30-100 minutes. Put the purified phosphor powder into the crucible chamber of a vacuum evaporation machine for evaporation for 1 -10 minutes, the degree of vacuum is 0.001-0.000001 mm Hg, the temperature is 100-1200° C., and the thickness of the obtained phosphor layer on the surface of the optical fiber is 0.00001-0.001 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com