Anti-slip mat plate, its production method and application

An anti-slip mat and anti-slip technology, which is applied in the direction of chemical instruments and methods, layered products, glass/slag layered products, etc., can solve the problems of damage failure, small friction coefficient, and poor applicability, and achieve applicability improvement and friction coefficient Large, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Such as figure 1 The shown anti-skid backing plate of the present invention comprises an anti-skid pad body 1, and the anti-skid pad body 1 is woven from jute material, and is soaked in modified asphalt in a molten state, wherein the modified asphalt is added with friction-enhancing material carbon black, so that The modified asphalt material is fully adsorbed in the pores of the jute fiber and in the weaving gap, and then the redundant modified asphalt material is discharged by steam heating method, and the anti-slip backing plate of the present invention is made after drying.

[0038] When utilizing the anti-slip backing plate of the present invention to do anti-slip treatment for equipment, it is only necessary to place the anti-slip backing plate between the equipment and the foundation, because the anti-slip backing body 1 of the anti-slip backing plate is woven by jute fibers, and its upper and lower contact surfaces have natural Rough surface, high adhesion modif...

Embodiment 2

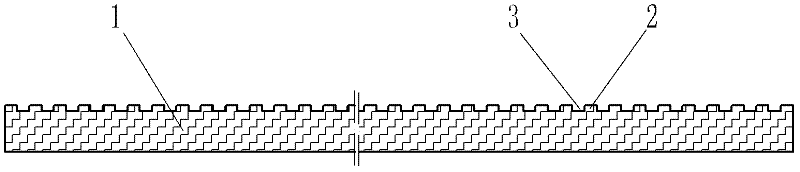

[0044] Such as figure 2 Shown anti-skid backing plate of the present invention, differs from embodiment one in that the anti-slip backing body 1 is woven from thread ropes made of sisal fibers. It is particularly pointed out that in order to improve the elasticity of the anti-slip backing plate, the When making the cord, a certain proportion of high elastic nylon fiber is also mixed into the sisal fiber. Then soak it with adhesive material, the adhesive material is mixed by emulsified asphalt, acrylic acid and cement, gypsum, mica powder and talcum powder, and rosin, a friction enhancing material, is added to make the adhesive material fully adsorbed into the pores of the fiber material and woven gap, and then mechanically extrude the excess adhesive material, and after drying, use a press to press and compact to obtain the anti-slip backing plate of the present invention. The slots 3 are arranged at intervals.

[0045] Since the surface of the anti-slip mat body 1 is provi...

Embodiment 3

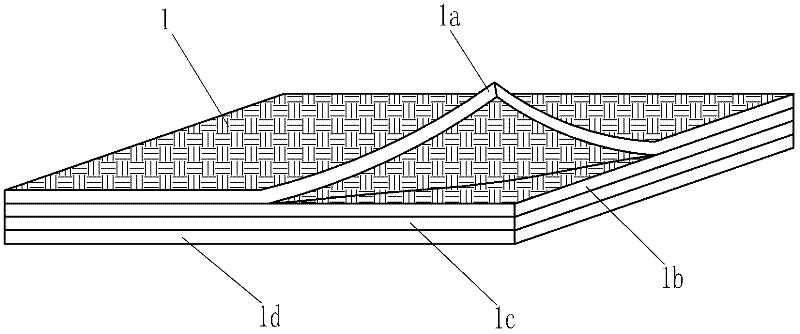

[0049] Such as image 3 The difference between the shown anti-slip backing plate of the present invention and the first embodiment is that the anti-slip mat body 1 is formed by laminating sub-anti-slip mat bodies 1a, 1b, 1c, and 1d. The sub-anti-skid mats 1a, 1b, 1c, 1d are respectively woven by wire ropes made of glass fibers, and soaked in emulsified asphalt, so that the floated asphalt materials are fully absorbed into the pores of glass fibers and the weaving gaps of wire ropes , and then squeeze out the excess emulsified asphalt material with a pressure roller and let it dry.

[0050] The advantage of this type of anti-slip pad is that the total thickness of the anti-slip pad can be controlled by changing the number of sub-anti-slip pads. In particular, each sub-anti-slip pad body in this anti-slip backing plate has independent and same anti-slip performance as the whole, so even if the sub-anti-slip pads are peeled off, the overall anti-slip performance will not be affe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com