Coating material and its preparation method

A technology of coating materials and raw materials, applied in coating and other directions, can solve the problems of complicated procedures, difficult industrialization, and large surface energy of nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

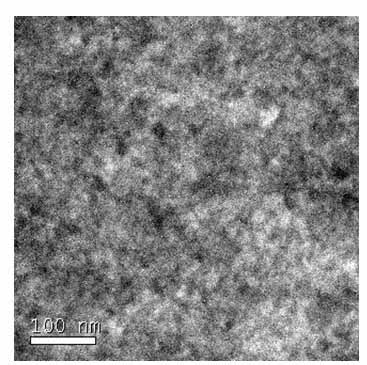

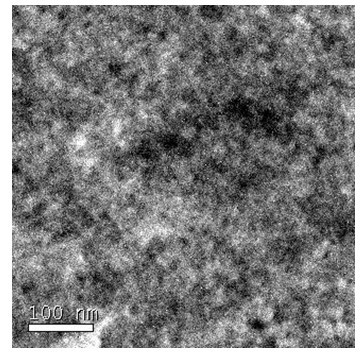

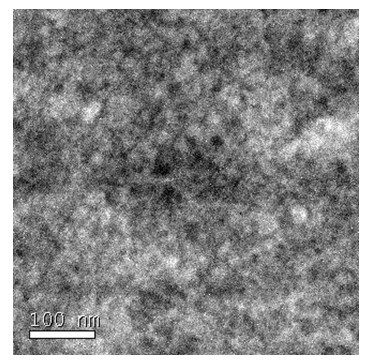

Image

Examples

Embodiment 1

[0044] Embodiment 1: The formula 1 of nano-modified organic-inorganic hybrid coating material is as follows:

[0045]

[0046]

[0047] In the reaction kettle, add 100 grams of xylene, 50 grams of carboxylated acrylic resin with a solid content of 50%, 80 grams of alkoxyacrylic resin with a solid content of 30%, 100 grams of methyl silicone resin with a solid content of 30%, and 0.6 grams of 731A sodium salt Powder, 0.6 g of X-405 wetting agent, 0.1 g of 013 defoamer, 0.2 g of BYK-333 leveling agent, slowly add 2 g of nano-modifier TriSilanolIsobutyl-POSS at 1000 rpm, within 5 to 10 minutes After the addition, continue to stir for 20-40 minutes, coat the film, and cure at 80° C. for 1 hour to obtain a nano-modified organic-inorganic hybrid coating material.

[0048] The pencil hardness of the coating is 3H, the gloss (Gloss 20°) is 95, the flexibility is 1mm, the impact strength is 60kg / cm, and the artificial accelerated aging resistance time is ≥1000 hours. Among them,...

Embodiment 2

[0049] Embodiment 2: The formula 2 of nano-modified organic-inorganic hybrid coating material is as follows:

[0050]

[0051] In the reaction kettle, add 45 grams of acetone, 25 grams of butyl acetate, 5 grams of isopropanol, 12 grams of titanium dioxide, 10 grams of aluminum powder, 0.6 grams of DP-19 dispersant, 0.6 grams of NP-9 wetting agent, 1.3 Gram A36 defoamer, 0.5 gram RM-2020 leveling agent, high-speed stirring 0.8 hour under 2200rpm rotating speed, then add 20 grams of epoxy acrylic resin of solid content 50%, 100 grams of solid content 50% hydroxyl acrylic resin, in Slowly add 12 grams of TriSilanolIsobutyl-POSS at 1400rpm, finish adding within 30 minutes, continue stirring for 30 minutes, coat the film, and cure at 90°C for 0.5 hours to obtain a nano-modified organic-inorganic hybrid coating material.

[0052] The hardness of the coated pencil is 4H, the flexibility is 1mm, the impact strength is 60kg / cm, and the artificial accelerated aging resistance time is...

Embodiment 3

[0053] Embodiment 3: The formula 3 of nano-modified organic-inorganic hybrid coating material is as follows:

[0054]

[0055] In the reaction kettle, add 20 grams of methyl amyl ketone, 5 grams of 200# solvent oil, 7 grams of titanium dioxide, 5 grams of barium sulfate, 2 grams of iron oxide, 0.6 grams of SN5027 dispersant, 0.6 grams of W-18, 1.3 grams SN154 defoamer, 0.5 g of RM-8 leveling agent, high-speed stirring at 3000 rpm for 30 minutes, then add 35 g of solid content 60% amido acrylic resin, 50 g of solid content of 70% hydroxy acrylic resin, 10 g of solid content 30% methyl silicone resin, slowly add 24 grams of TriSilanolIsobutyl-POSS at 500rpm, finish adding within 30 minutes, continue to stir for 60 minutes, coat the film, cure at 50°C for 12 hours, and obtain nano-modified organic-inorganic hybrid coating material.

[0056] Coating pencil hardness 5H, flexibility 1mm, impact strength 60kg / cm, artificial accelerated aging resistance time ≥ 1000 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com