Method for preparing ordered coaxial structural micro and nano fibers

A technology of micro-nano fibers and ordered arrangement is applied in the field of preparation of micro-nano fibers of ordered coaxial structure, which can solve the problems of low proportion of conductive polymers, limiting the application of composite fibers, reducing the electrical conductivity of fiber membranes, and the like. Achieve the effect of eliminating secondary pollution, avoiding excessive contact, and having a high degree of orderly arrangement of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

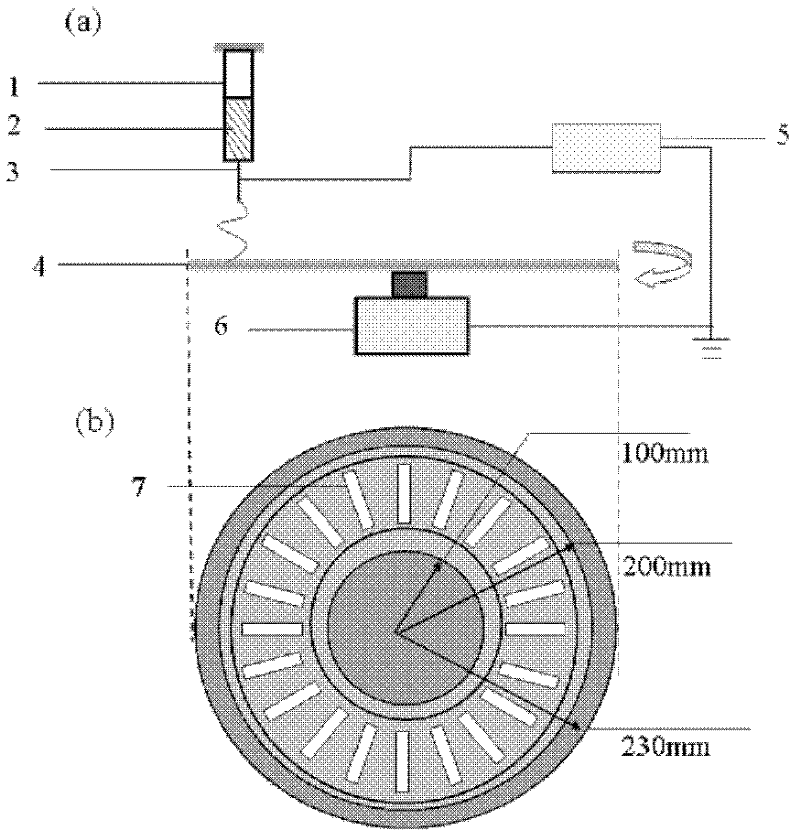

[0012] The rotating disc type electrospinning device (belonging to the inventor's invention patent) used in this embodiment includes a syringe 1, a spinning solution 2, an electrospinning nozzle 3, a rotating disc 4, a high-voltage power supply 5, a motor 6 and a The plastic substrate (or disk collector) 7 of rectangular slit groove; When its rotating disk type electrospinning device prepares the PMMA fiber of orderly arrangement, carries out electrospinning precursor polymethyl methacrylate (PMMA first) ) solution preparation: 1.5 gram of PMMA is dissolved in N, N dimethylformamide (DMF, 4 gram) and tetrahydrofuran (THF, 4 gram) solvent that mass ratio is 1: 1 by 1.5 gram, and magnetic stirring at normal temperature obtains PMMA for 3 hours DMF / THF solution is used as the precursor of electrospinning; the spinning device adopts a rotating disc type electrospinning device, and the height of the electrospinning nozzle 3 relative to the rotating disc 4 is continuously adjustable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com