Preparation method of slow-release pesticide

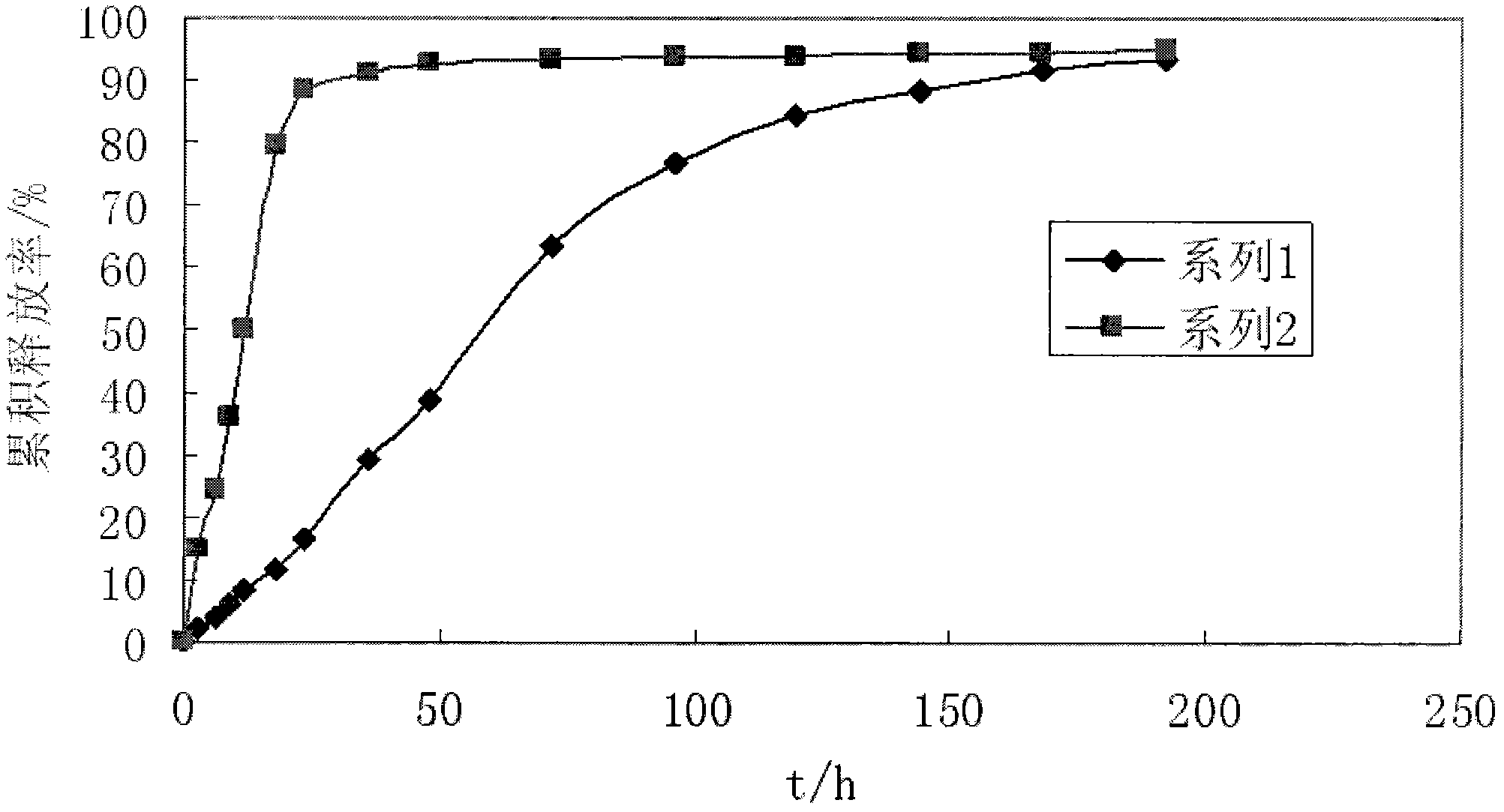

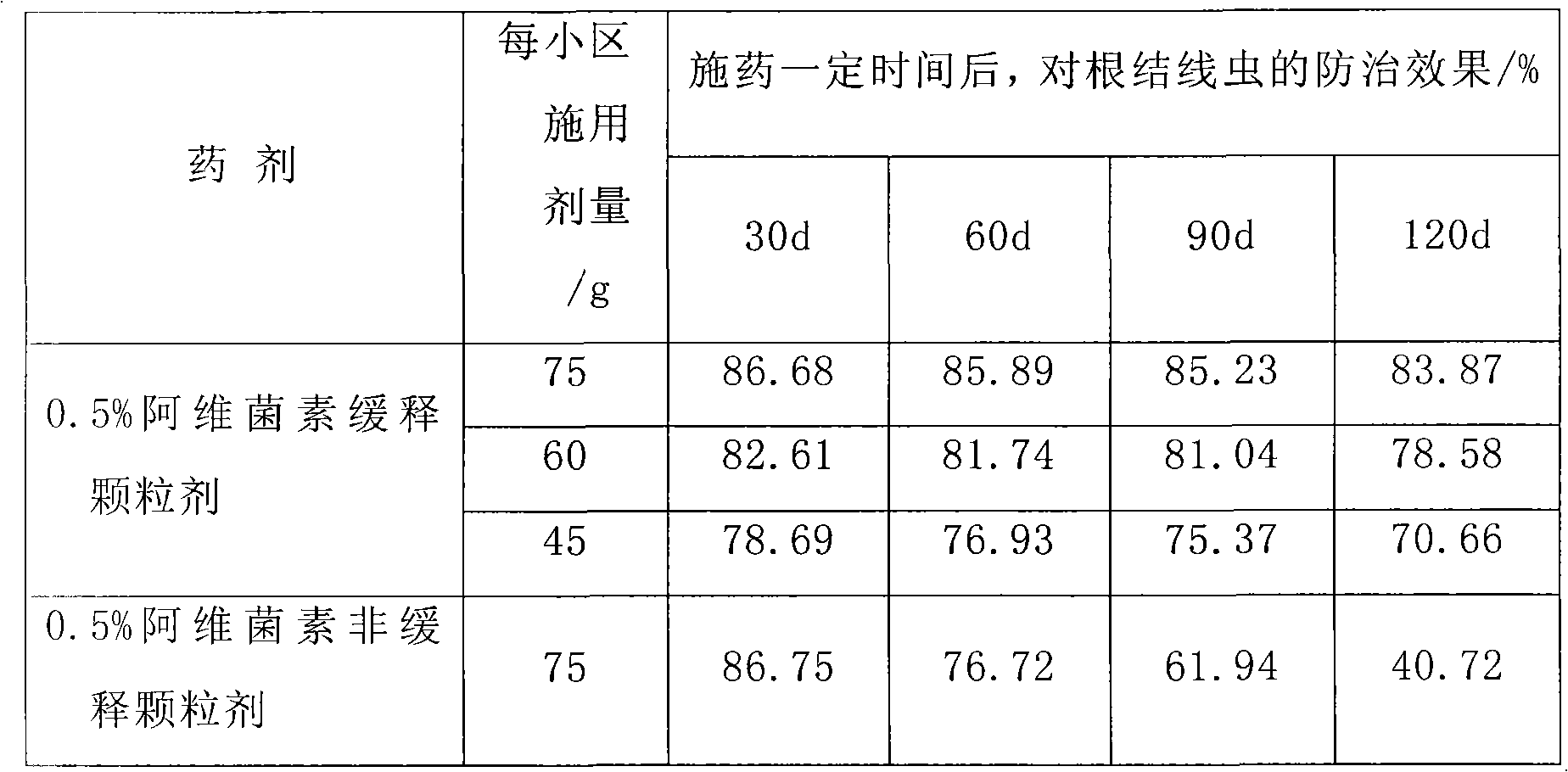

A technology for slow-release pesticides and pesticides, applied in the field of pesticides, can solve the problems of low preparation content and complicated process, and achieve the effects of maintaining stable release, prolonging release time, and improving slow-release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1 Preparation of Diazinon Sustained Release Tablets

[0016] Diazinon 5.0% (weight)

[0017] Silica 2.0% (weight)

[0018] Liquid paraffin 0.5% (weight)

[0019] Polyvinyl alcohol 5.0% (weight)

[0020] General Clay Top up

[0021] a) Slowly add 53g of 95% diazinon crude oil into 20g of white carbon black, stir and mix evenly after fully absorbing.

[0022] b) Slowly add 5 g of liquid paraffin into a) under constant stirring.

[0023] c) The product of step b), 872g of general clay and 50g of polyvinyl alcohol were uniformly mixed, an appropriate amount of water was added thereto, compressed into tablets with a tablet machine, and then dried.

[0024] A 5.0% diazinon sustained-release tablet was obtained.

Embodiment 2

[0025] Example 2 Preparation of trichlorfon and chlorpyrifos sustained-release granules

[0026] Trichlorfon 3.0% (weight)

[0027] Chlorpyrifos 1.5% (weight)

[0028] DMF 1.0% (weight)

[0029] Octadecyltrimethylammonium bromide 1.0% (weight)

[0030] Zeolite 10.0% (weight)

[0031] Polyethylene glycol 1.0% (weight)

[0032] Yellow dextrin 10.0% (weight)

[0033] General Clay Top up

[0034] a) Add 34 g of 90% trichlorfon powder, 16 g of 95% chlorpyrifos powder and 10 g of octadecyltrimethylammonium bromide into 10 g of DMF, and stir to fully dissolve it.

[0035] b) Fully adsorb a) with 100 g of zeolite.

[0036] c) Add 10 g of polyethylene glycol to b).

[0037] d) Mix the product of step c), 100g of yellow dextrin and 720g of general clay powder, add an appropriate amount of water therein, mix with a small kneader, and granulate the obtained mixture with a small extrusion granulator, Dry and sieve after machine sizing.

[0038] A 4.5% trichlorfon·chlorpyrifos sus...

Embodiment 3

[0039] Example 3 Preparation of propiconazole sustained-release granules

[0040] Propiconazole 1.0% (weight)

[0041] Cetyltrimethylammonium bromide 0.5% (weight)

[0042] Silica 1.0% (weight)

[0043] Engine oil 0.5% (weight)

[0044] Sodium carboxymethyl cellulose 5.0% (weight)

[0045] General Clay Top up

[0046] a) Add 5 g of cetyltrimethylammonium bromide into 11 g of 95% propiconazole crude oil, stir and mix evenly, and then use 10 g of white carbon black to adsorb it.

[0047] b) Add 5g of engine oil to a).

[0048] c) The product of step b), 919g of general clay and 50g of sodium carboxymethylcellulose were mixed and then granulated, dried and sieved.

[0049] 1% propiconazole sustained-release granules were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com