Iron-based mixed powder used for powder metallurgy

A mixed powder and powder metallurgy technology, applied in the field of iron-based mixed powder, can solve the problems of difficult density, shortened mold life, slow diffusion of alloying elements, etc., and achieve the effect of high forming density, low pull-out force and excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

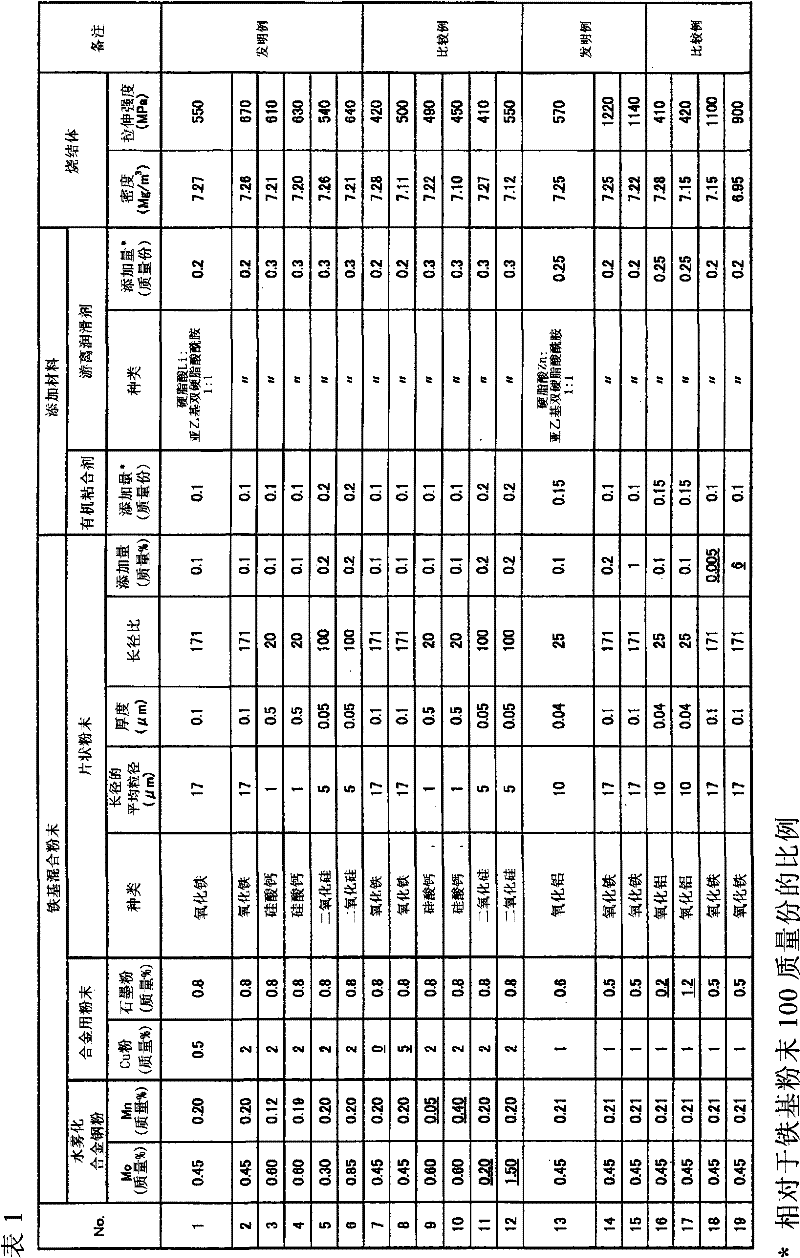

[0081] As the iron-based powder, the water-atomized alloy steel powder shown in Table 1 was used. In addition, the addition amounts of Cu powder and graphite powder are as shown in Table 1. In addition, stearic acid monoamide and ethylene bis stearic acid amide were used as organic binders.

[0082] Add flake powder and free lubricant to the above-mentioned iron-based powder in various proportions, and then mix to prepare iron-based mixed powder for powder metallurgy. In addition, as the flaky powder, flaky silica (manufactured by AGC Essaitec), petal-shaped calcium silicate (Florite, made by Tokuma), plate-like alumina (Seraf, made by Kincematec) and flaky alumina were used. Iron (AM-200, manufactured by Chilan Industries). In addition, lithium stearate, zinc stearate, and ethylenebisstearamide were used as free lubricants.

[0083] In addition, the flaky powder was observed using a scanning electron microscope, and the average value of each aspect ratio of 50 particles se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com