A method for surface treatment of chrome-free zinc coating for NdFeB permanent magnet materials

A permanent magnet material and surface treatment technology, applied in anti-corrosion coatings, metal-free paints, etc., can solve problems such as easy rust and corrosion, magnetic performance decline or damage, and poor corrosion resistance of NdFeB alloys, etc., to achieve High corrosion resistance, easy handling, and the effect of improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

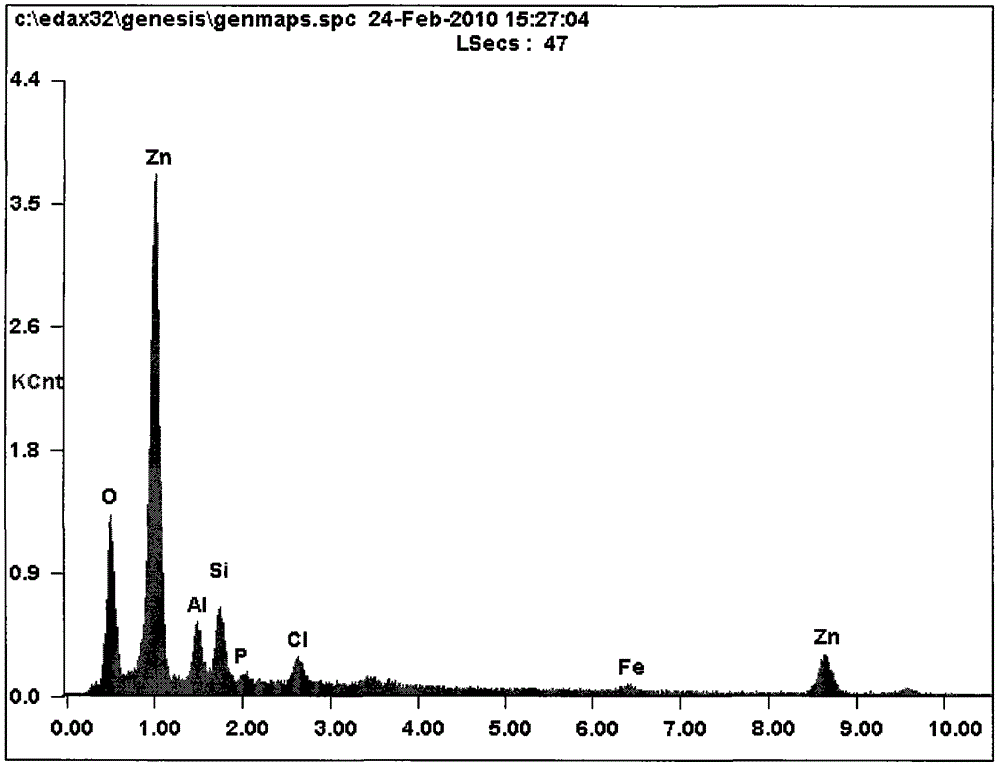

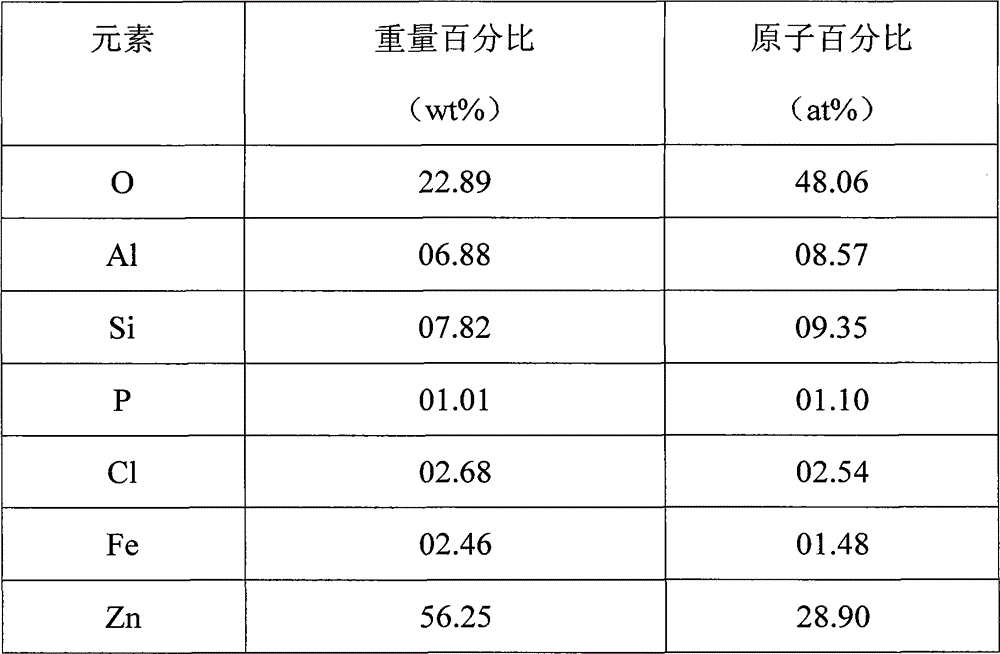

Image

Examples

Embodiment 1

[0021] Polish 2.3 kg of 8*8*7mm sintered NdFeB permanent magnet material in a vibration mill for 2 hours. After degreasing with sodium phosphate 20g / liter, sodium carbonate 10g / liter and sodium hydroxide 10g / liter, blow dry. For sandblasting, please refer to the surface pretreatment method (CN101373650A) of the dry sandblasting NdFeB permanent magnet material applied by the inventor in 2007 for ultrasonic washing. The chromium-free zinc-aluminum liquid is by weight percentage: 35% of flaky zinc powder (the particle size of zinc powder is 800 mesh), 5% of flaky aluminum powder (the particle size of aluminum powder is 800 mesh), 0.15% of polytetrafluoroethylene (polytetrafluoroethylene The particle size of tetrafluoroethylene is 400 mesh), magnesia 0.15% (the particle size of magnesium oxide is 120 mesh), hydrocarbon methyl cellulose 3%, polyethylene glycol 1%, alkylphenol polyoxyethylene ether 2%, 601 Epoxy resin 8%, silane coupling agent KH-5501%, phytic acid 1%, the rest is ...

Embodiment 2

[0024] Put 2.3 kg of sintered NdFeB permanent magnet material of 24*99*7mm in the vibration mill for 2 hours. After degreasing with sodium phosphate 20g / liter, sodium carbonate 10g / liter and sodium hydroxide 10g / liter, blow dry. For sandblasting, please refer to the surface pretreatment method (CN101373650A) of the dry sandblasting NdFeB permanent magnet material applied by the inventor in 2007 for ultrasonic washing. The chromium-free zinc-aluminum liquid is as follows by weight percentage: the content of flaky zinc powder is 20% (the particle size of zinc powder is 1000 mesh), the content of flaky aluminum powder is 10% (the particle size of aluminum powder is 1000 mesh), and the content of tin powder is 1% (tin powder is 1000 mesh). Powder particle size is 400 mesh), polytetrafluoroethylene 4% (polytetrafluoroethylene particle size is 200 mesh), hydrocarbon methyl cellulose 1%, polyethylene glycol 1%, alkylphenol polyoxyethylene ether 2% , 14% of 604 epoxy resin, 1% of sil...

Embodiment 3

[0027] Polish 2.3 kg of D24.99*7mm sintered NdFeB permanent magnet material in a vibration mill for 2 hours. After degreasing with sodium phosphate 20g / liter, sodium carbonate 10g / liter and sodium hydroxide 10g / liter, blow dry. For sandblasting, please refer to the surface pretreatment method (CN101373650A) of the dry sandblasting NdFeB permanent magnet material applied by the inventor in 2007 for ultrasonic washing. The chromium-free zinc-aluminum liquid is as follows by weight percentage: the content of flaky zinc powder is 30% (the particle size of zinc powder is 900 mesh), the content of flaky aluminum powder is 10% (the particle size of aluminum powder is 900 mesh), and the content of magnesium powder is 0.15%. (the particle size of magnesium powder is 150 mesh), polytetrafluoroethylene 4.5% (polytetrafluoroethylene particle size is 300 mesh), hydrocarbon methyl cellulose 3%, polyethylene glycol 1%, alkylphenol polyoxyethylene ether 2%, 607 epoxy resin 15%, silane coupli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com