Magnetic refrigeration material compound with high magnetic entropy change and its preparation method

A technology of magnetic refrigeration materials and compounds, applied in the direction of magnetic materials, heat exchange materials, chemical instruments and methods, etc., can solve problems such as unreported processes, achieve the effects of controlling oxygen content, simple preparation process, and improving inherent characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

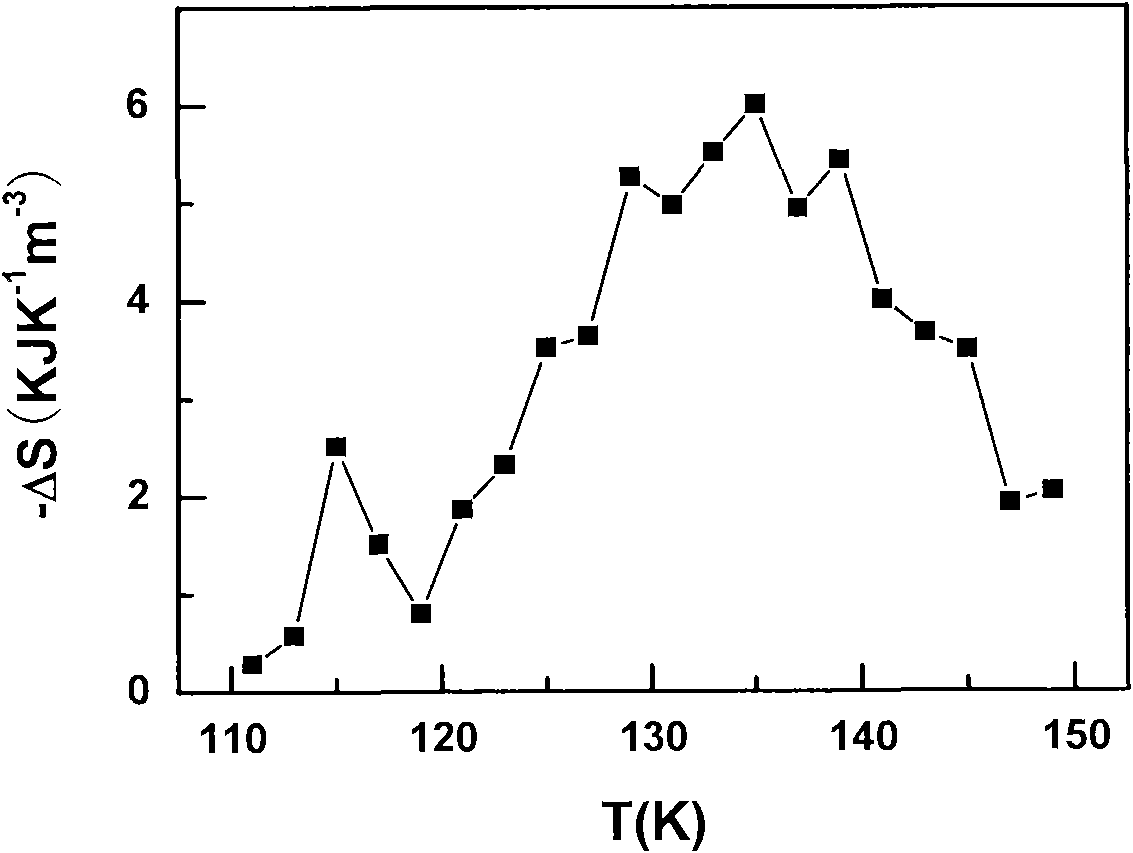

Image

Examples

preparation example Construction

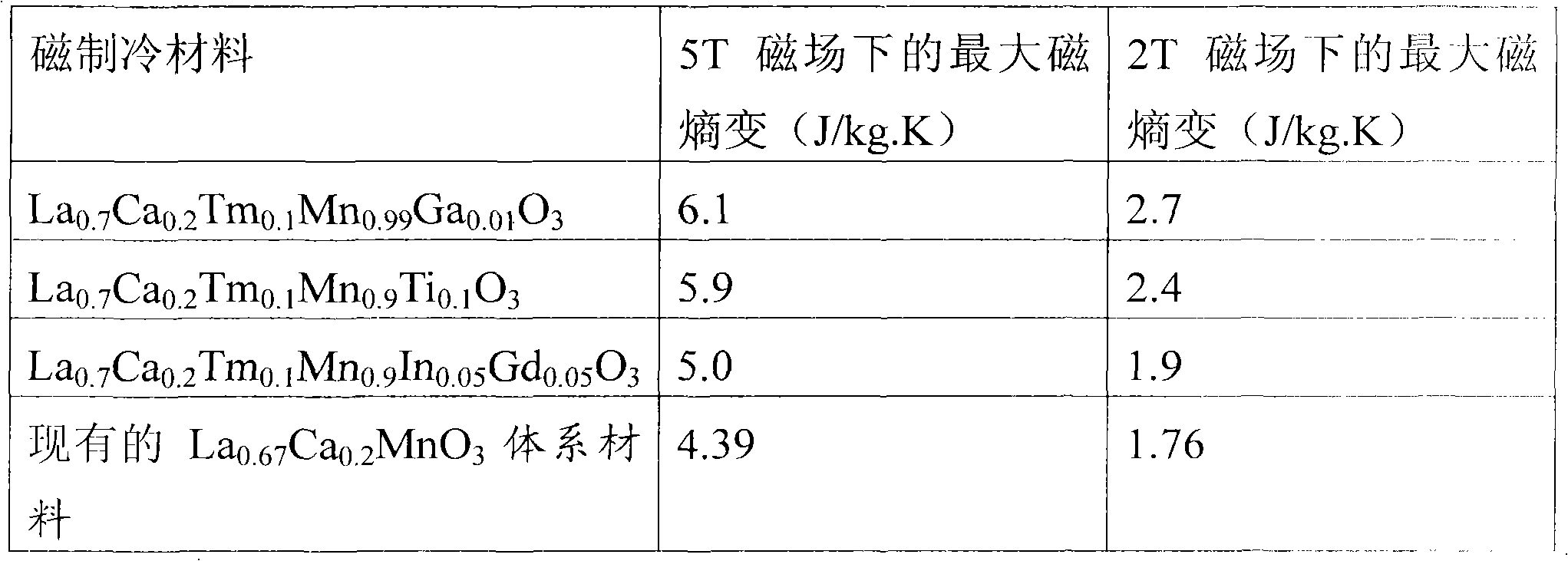

[0023] Different from the preparation of traditional magnetic refrigeration materials, the present invention uses manganese perovskite LaMnO 3 The structural system is the matrix, and calcium Ca and thulium Tm are used as the matrix component ions. A solid-state reaction method is used to directly introduce auxiliary doping ions M with unequal Mn sites into the raw material formula to prepare a high magnetic entropy change. The magnetic refrigeration material (La 0.7 Ca 0.2 T m 0.1 )Mn 1-x m x o 3 (03+ / Mn 4+ Valence balance, so as to achieve the purpose of controlling the number of point defects in the crystal structure.

[0024] The following specifically describes the magnetic refrigeration material of the present invention (La 0.7 Ca 0.2 T m 0.1 )Mn 1-x m x o 3 preparation process.

[0025] The present invention adopts the solid phase reaction method for batching to prepare the mixture used for firing. Specifically, a certain amount of La 2 o 3 Dry at a tem...

Embodiment 1

[0032] First, a certain amount of La 2 o 3 Dry at 600°C for 10 hours (h) to remove crystal water. Weigh the dried La according to the atomic ratio La: Ca: Tm: Mn: Ga = 07: 0.2: 0.1: 0.99: 0.01 2 o 3 , MnCO 3 , CaCO 3 , Tm(NO 3 ) 3 and Ga(NO 3 ) 3 , formulated into a mixture. Preferably, before preparing the mixture, the MnCO 3 and CaCO 3 For drying, for example, MnCO 3 and CaCO 3 Dry at a temperature of 100°C to 300°C for 6 to 12 hours. Then, add absolute ethanol according to the weight ratio of the mixture to absolute ethanol at 1:1.5, and ball mill and mix for 4 hours in a planetary ball mill with a rotational speed of 300 rpm (r / min), to obtain a ball mill. Afterwards, the prepared ball mill was dried at a temperature of 100° C. for 30 h. Put the dried mixture into a crucible (such as alumina crucible, graphite crucible, etc.), and calcinate at 1000° C. for 24 hours to obtain a precursor. Then, after the precursor is ground repeatedly, it is pressed under a ...

Embodiment 2

[0036] First, a certain amount of La 2 o 3 After drying at 700 °C for 7 h, the MnCO 3 、TiO 2 and CaCO 3 Dry at 100°C for 12h. Then, according to the atomic ratio La:Ca:Tm:Mn:Ti=07:0.2:0.1:0.9:0.1, weigh the dried La 2 o 3 , MnCO 3 , CaCO 3 and TiO 2 and Tm(NO 3 ) 3 , formulated into a mixture. Afterwards, the prepared mixed material and absolute ethanol were added into absolute ethanol at a weight ratio of 1:1, and then ball milled and mixed for 4 hours in a planetary ball mill with a rotational speed of 300 r / min to obtain a ball mill. Afterwards, the prepared ball mill was dried at a temperature of 150° C. for 20 h. Next, the dried mixture was put into an alumina crucible, and calcined at 1100° C. for 20 hours to obtain a precursor. Afterwards, the precursor is repeatedly ground, and pressed under a pressure of 200 MPa into a small round block with a diameter of about 20 mm and a thickness of about 5 mm to obtain a mixture for firing. Put the round block-shaped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic entropy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com