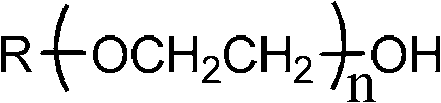

Preparation method of fatty alcohol polyoxyethylene ether

A technology of alcohol polyoxyethylene ether and fat, which is applied in the field of preparation of fatty alcohol polyoxyethylene ether, can solve the problems of product performance impact, narrow distribution, high content of free fatty alcohol, etc., achieve fast reaction speed, less catalyst consumption, The effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Mix 1g of magnesium carbonate and 60g of magnesium nitrate into 500g of potassium hydroxide aqueous solution containing 7.8% by weight of potassium hydroxide, stir well at 25°C, filter, place in an oven at 120°C, dry at 900°C Calcined for 6 hours to form granules and then sieved for use, and 48 g of composite basic catalysts with a particle size equal to or less than 0.1 mm were obtained by sieving.

[0040] Weigh the number of carbon atoms as C 8 ~C 10 280g of aliphatic alcohol joins in 1L autoclave, adds dodecyl dimethyl benzyl ammonium chloride 0.28g, above-mentioned composite basic catalyst 0.14g in autoclave successively while stirring, and autoclave uses N 2 permutation three times, at N 2 Under the condition of protection, heat up to 120°C, add ethylene oxide, after the amount of ethylene oxide added reaches 264g at 130°C and 0.01MPa, continue the reaction at 130°C and 0.01MPa for 0.5h, cool to 70°C, Blowing to obtain the fatty alcohol polyoxyethylene ether pr...

Embodiment 2

[0045] Mix 60g of calcium carbonate and 20g of strontium nitrate into 500g of sodium hydroxide aqueous solution containing 4% by weight of sodium hydroxide, stir thoroughly at 30°C, filter, dry in an oven at 120°C, and dry at 900°C Calcined for 6 hours to form granules and then sieved for use, and 70 g of composite basic catalysts with a particle size equal to or less than 10 mm were obtained by sieving.

[0046] Weigh the number of carbon atoms as C 28 ~C 30 287g of aliphatic alcohol joins in 1L autoclave, adds dodecyl dimethyl benzyl ammonium chloride 28g, above-mentioned composite basic catalyst 14g in autoclave successively while stirring, and autoclave uses N 2permutation three times, at N 2 Under the condition of protection, heat up to 120°C, add ethylene oxide, after the amount of ethylene oxide added reaches 277g at 200°C and 20MPa, continue to react at 200°C and 20MPa for 0.5h, cool to 70°C, discharge , to obtain the fatty alcohol polyoxyethylene ether product.

...

Embodiment 3

[0051] Mix 20g of barium carbonate and 1g of barium nitrate into 500g of lithium hydroxide aqueous solution containing 15.8% by weight of lithium hydroxide, stir well at 20°C, filter, dry in an oven at 120°C, and dry at 900°C Calcined for 6 hours to form granules and then sieved for use, and 14 g of composite basic catalysts with a particle size equal to or less than 1 mm were obtained by sieving.

[0052] Weigh the number of carbon atoms as C 12 ~C 14 The aliphatic alcohol 76g joins in the 1L autoclave, adds dodecyl dimethyl benzyl ammonium chloride 0.76g, the composite basic catalyst 0.076g of above-mentioned preparation successively in autoclave while stirring, autoclave uses N 2 permutation three times, at N 2 Under the condition of protection, heat up to 120°C, add ethylene oxide, after the amount of ethylene oxide added reaches 500g at 170°C and 10MPa, continue to react at 170°C and 10MPa for 0.5h, cool to 70°C, discharge , to obtain the fatty alcohol polyoxyethylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com