Ecological carbon-fiber composite, preparation method thereof and sewage treatment reactor containing ecological carbon-fiber composite

A fiber composite material, ecological carbon technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc. problems, to achieve the effect of reducing the number of replacements, prolonging the service life, and reasonable pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

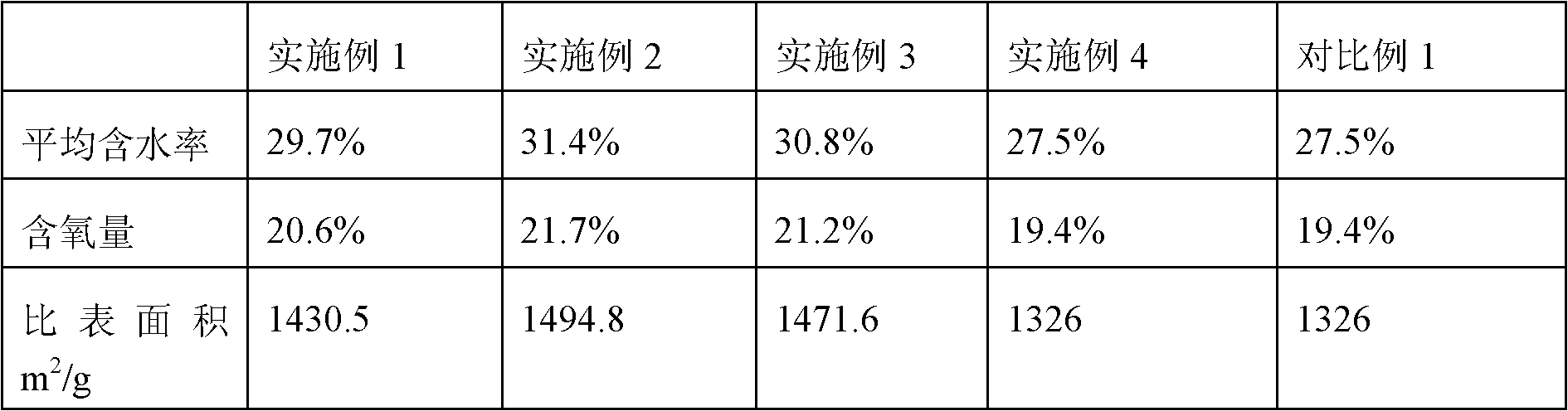

Examples

preparation example Construction

[0036] In a typical embodiment of the present invention, the preparation method of the above-mentioned ecological carbon fiber composite material includes the following steps: preparing bioactive carbon fiber; preparing polypropylene fiber mesh cloth; using bioactive carbon fiber as the core layer, using polypropylene fiber mesh cloth as The outer layer is wrapped around the periphery of the core layer, forming an ecological carbon fiber composite material. The preparation process of the ecological carbon fiber composite material is simple and suitable for mass production.

[0037] Among them, the step of preparing bioactive carbon fiber includes: using one or more of polyacrylonitrile fiber, viscose fiber and pitch fiber as raw material, performing pre-oxidation treatment to form pre-oxidized fiber, carbonizing and activating the pre-oxidized fiber processed to form bioactive carbon fibers.

[0038] The step of preparing biologically active carbon fiber in the present invent...

Embodiment 1

[0057] Raw materials: polyacrylonitrile fiber mat with a thickness of 0.5mm, polypropylene fiber filaments with a diameter of 200D, and polypropylene fiber filaments and polyester fiber filaments with a diameter of 150D (manufacturing company: Changzhou Bangguan Chemical Co., Ltd.).

[0058] Preparation:

[0059] After the polyacrylonitrile fiber mat is gradually heated to 200°C at a rate of 3°C / min, pre-oxidation treatment is carried out for 50 minutes to form pre-oxidized filaments; the pre-oxidized filaments are gradually heated at a rate of 10°C / min under a nitrogen atmosphere. After heating up to 700°C, use water vapor as an activating agent for 30 minutes of carbonization and activation treatment to form bioactive carbon fibers.

[0060] The biologically active carbon fibers are treated with ultrasonic waves with a frequency of 50KHz for 10 minutes in a mixed solution prepared by a hydrogen peroxide solution with a concentration of 30% and an ammonia solution with a conc...

Embodiment 2

[0064] Raw materials: viscose fiber mat with a thickness of 0.5mm, polypropylene fiber yarn with a diameter of 500D, and polypropylene fiber yarn and polyester fiber yarn with a diameter of 600D (manufacturing company: Shandong Hailong Co., Ltd.).

[0065] Preparation:

[0066] Gradually raise the temperature of the viscose fiber mat to 300°C at a rate of 5°C / min, and then perform a pre-oxidation treatment for 150 minutes to form a pre-oxidized wire; gradually raise the temperature of the pre-oxidized wire at a rate of 30°C / min in a nitrogen atmosphere After reaching 800°C, use water vapor as an activating agent to perform carbonization and activation treatment for 90 minutes to form bioactive carbon fibers.

[0067] The bioactive carbon fiber is treated with a frequency of 100KHz in a hydrogen peroxide solution with a concentration of 30% for 60 minutes to perform the first surface active treatment; In the 25% ammonia solution, the ultrasonic wave with a frequency of 100KHz ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com