Silicon/graphene composite material, and preparation method and application of the same

A composite material and graphene technology, applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., to achieve the effect of improving low specific capacity and high degree of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

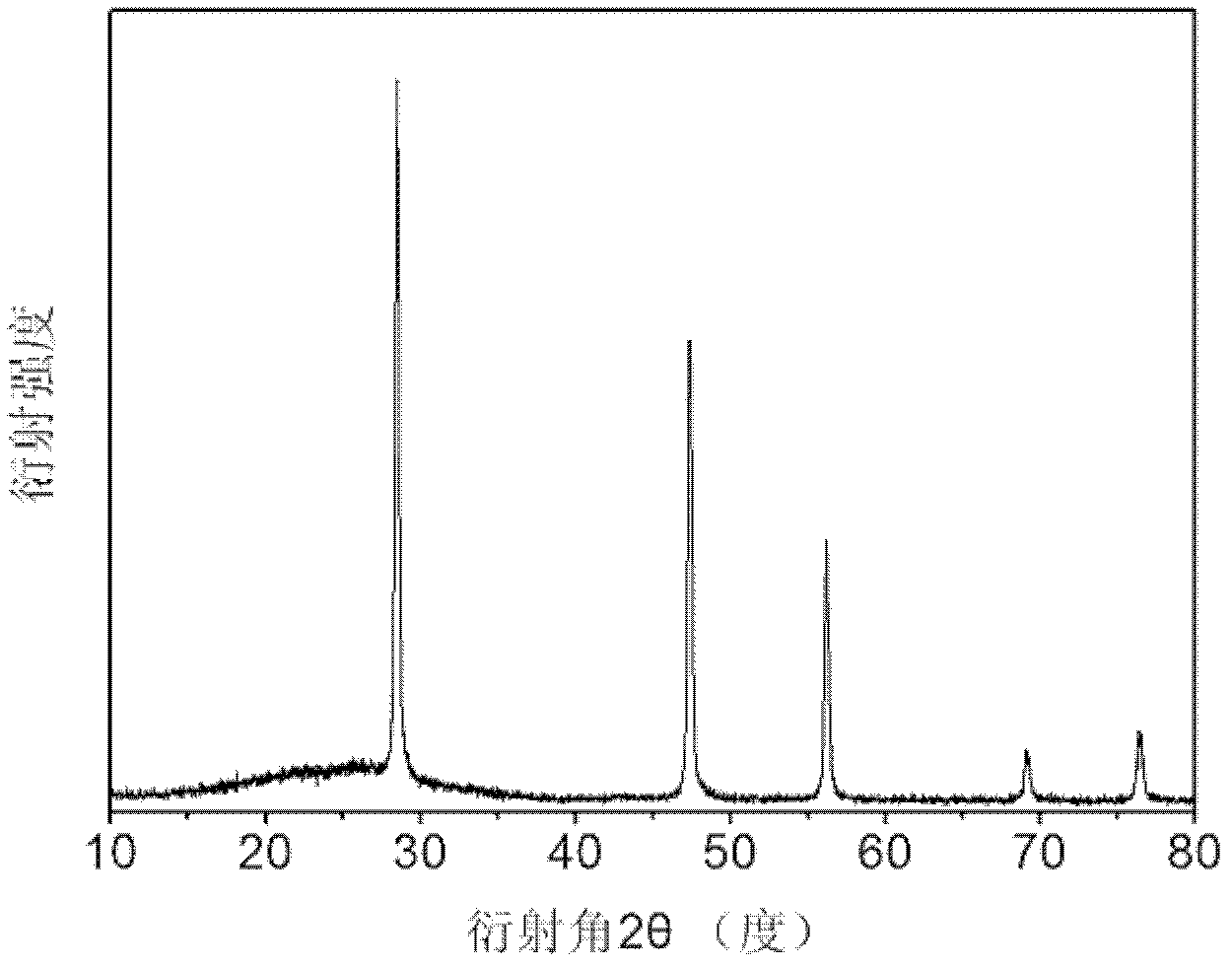

[0026]The mass ratio of silicon nanoparticles: graphite oxide is mixed in a ratio of 4: 1, and water is used as a dispersion solvent, wherein the mass percentage concentrations of silicon nanoparticles and graphite oxide in the aqueous dispersion are 0.4% and 0.1%, respectively, It was ultrasonically mixed at a power of 40 kHz in a water bath for 0.3 h to obtain a uniform graphite oxide-silicon nanoparticle mixed solution. The solution was freeze-dried at -70°C for 24 hours, and the resulting freeze-dried powder was raised from room temperature to 700°C at a rate of 2°C / min under nitrogen protection, and then cooled to room temperature at a rate of 10°C / min after constant temperature for 2 hours. . Add the above materials into 10% hydrofluoric acid aqueous solution for immersion for 3 hours, then wash and dry with ethanol. A silicon / graphene composite material is thus obtained.

[0027] Characterization of silicon / graphene composites:

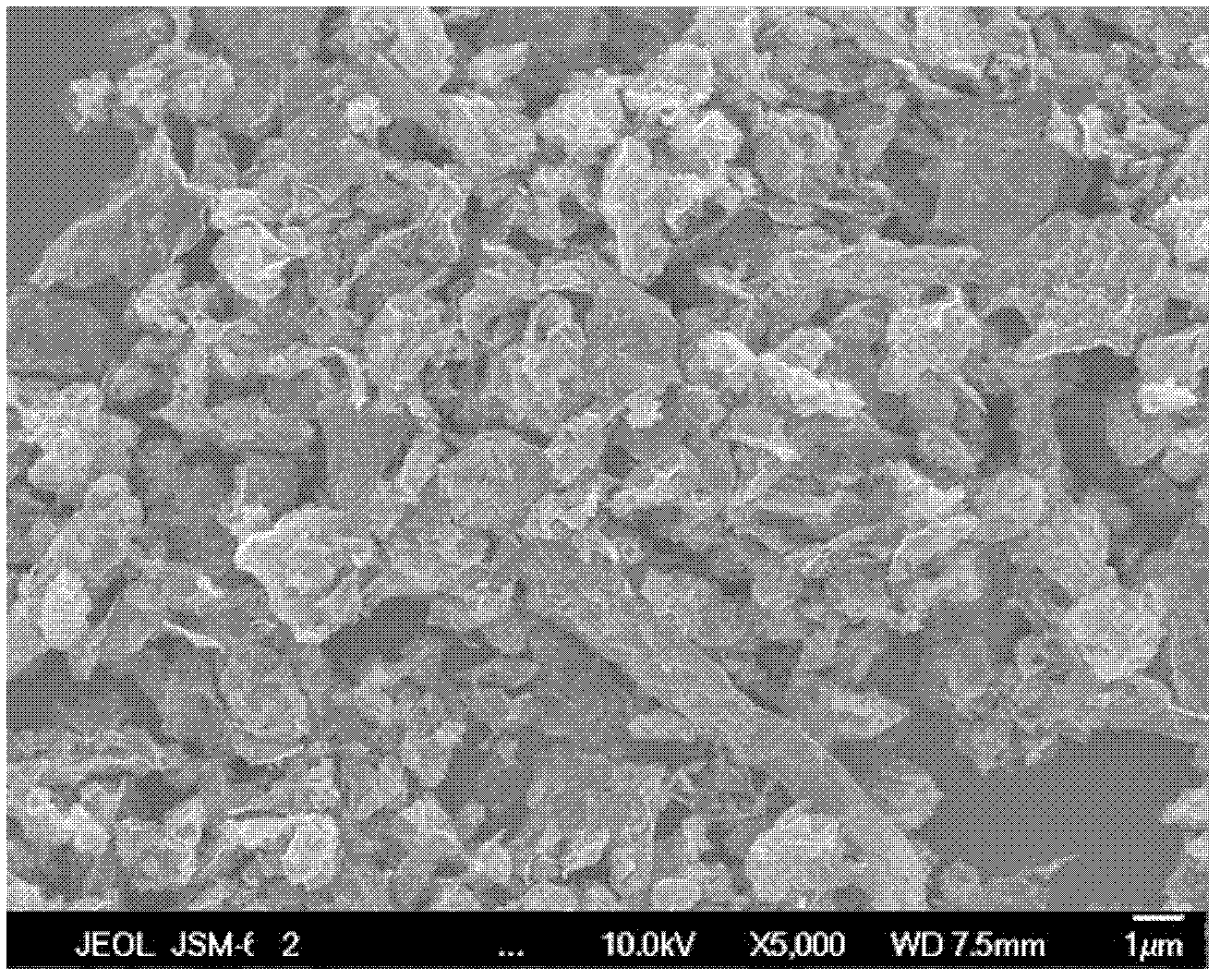

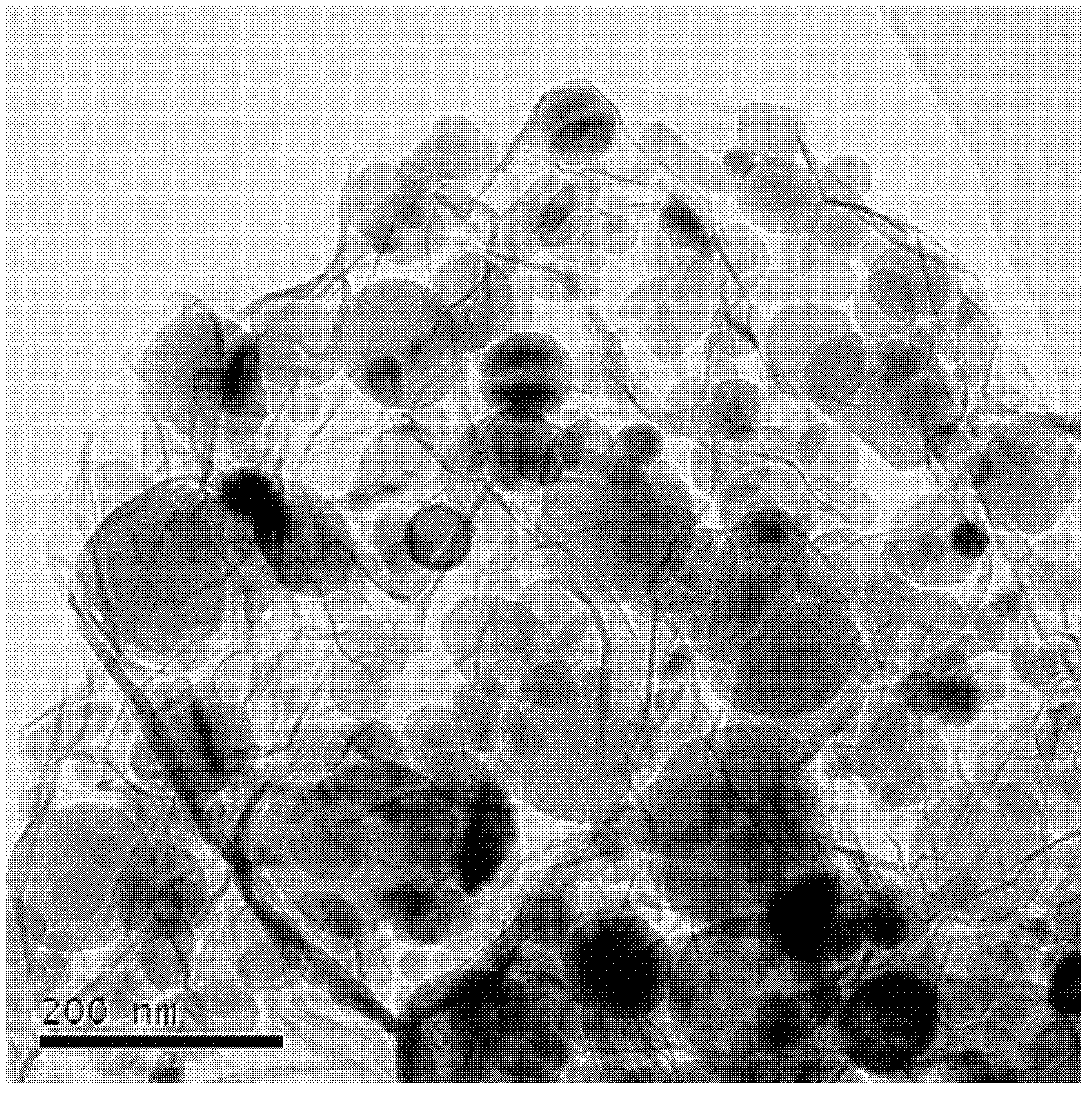

[0028] The morphology and size of the...

Embodiment 2

[0035] According to the mass ratio of silicon nanoparticles: graphite oxide, it is mixed in the ratio of 10:1, water is used as the dispersion solvent, the mass percent concentration of silicon nanoparticles and graphite oxide in the aqueous dispersion is 1% and 0.1%, freeze-dried The temperature in the step was replaced with -60°C, and then the silicon / graphene composite material was prepared according to the same method as in Example 1, except that the reduction temperature was 500°C, and the constant temperature time was 3h.

[0036] The positive pole, negative pole, electrolyte and battery assembly of simulated battery are identical with embodiment 1, and the composition of gained silicon / graphene composite material and the test result of simulated battery are listed in Table 1, and scanning electron microscope photograph is as follows Figure 5 shown. The apparent form of the silicon / graphene composite material is particles, the interior is a pore structure, and the parti...

Embodiment 3

[0038] According to the ratio of 0.2:1 mass ratio of silicon nanoparticles: graphite oxide, water is used as the dispersion solvent, and the mass percent concentrations of silicon nanoparticles and graphite oxide in the aqueous dispersion are 0.1% and 0.5%, respectively, freeze-dried The temperature of the step is replaced by -10°C, and then the silicon / graphene composite is prepared by the same method as in Example 1, except that the reduction temperature is 800°C, the constant temperature time is 1h, and the concentration is 10% by mass. Immerse in hydrofluoric acid aqueous solution for 0.5h.

[0039] The positive electrode, negative electrode, electrolyte and battery assembly of the simulated battery are the same as in Example 1, and the composition of the obtained silicon / graphene composite material and the test results of the simulated battery are listed in Table 1. The apparent form of the silicon / graphene composite material is particles, the interior is a pore structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com