Graphene/modified titanium dioxide nano sol composite material and preparation method thereof

A titanium dioxide and nano-sol technology, applied in titanium dioxide, graphene, chemical instruments and methods, etc., can solve the problems of uneven size and distribution of nanoparticles, affect product performance, consume large heat energy, etc., and achieve large-scale industrial production, The effect of chemical and thermal stability, optimized performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

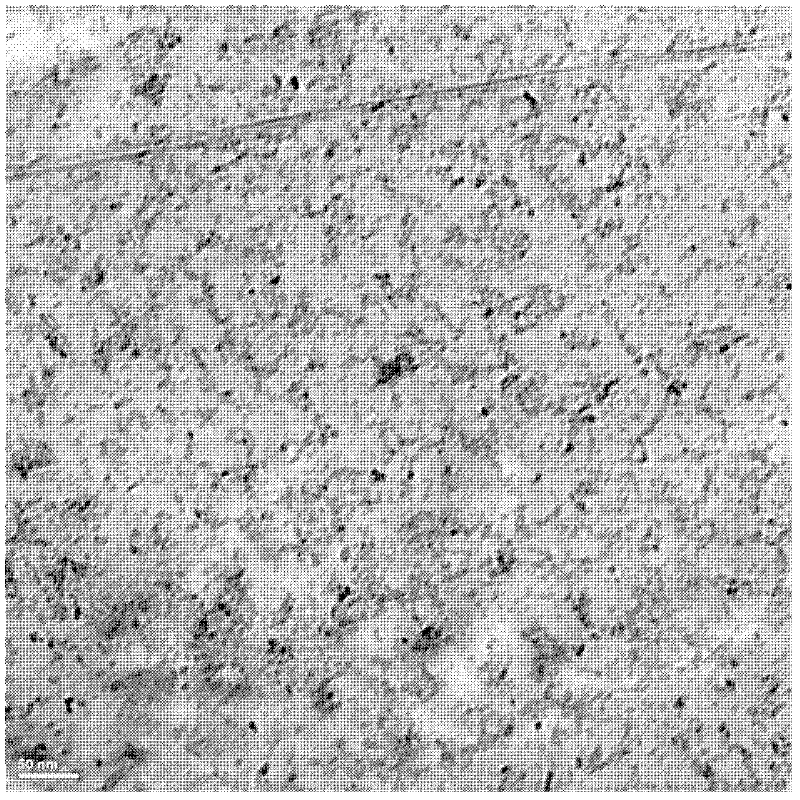

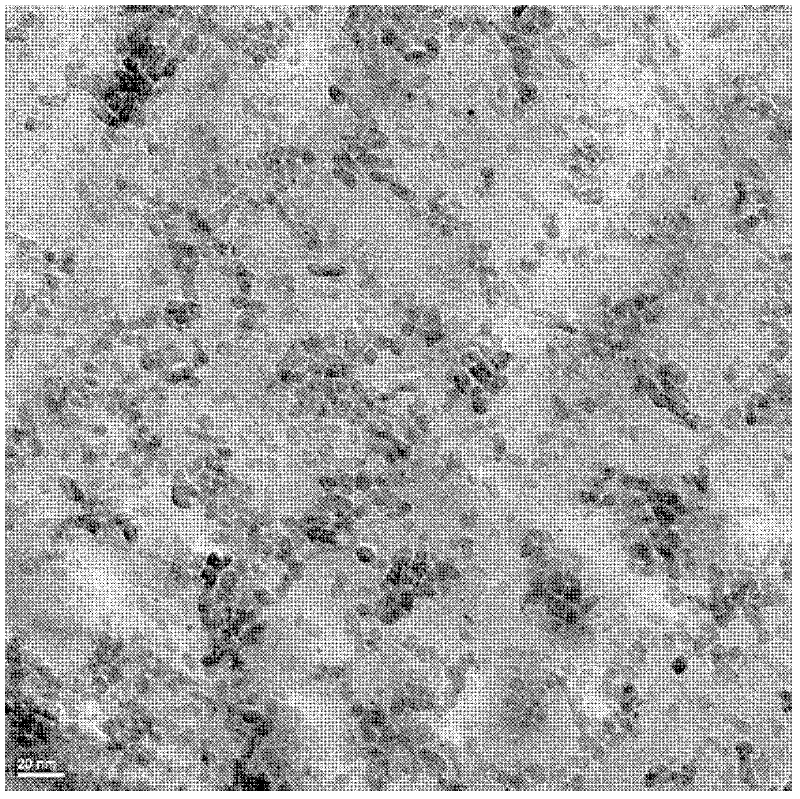

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of graphene / modified titanium dioxide nano-sol composite material, comprising:

[0033] Provide titanium dioxide nano-sol and graphene;

[0034] Using chloroauric acid as raw material, mercaptan as surfactant, and tetraoctyl ammonium bromide as phase transfer agent, a reduction reaction occurs under the action of mercaptocarboxylic acid and sodium borohydride to obtain a modified gold nano-sol;

[0035] The modified gold nano sol and the titanium dioxide nano sol are respectively dispersed in an organic solvent and then mixed to obtain a titanium dioxide sol modified with the gold nano sol.

[0036] The titanium dioxide sol modified by the gold nano sol is mixed with the toluene solution of the graphene, dispersed uniformly and then filtered to obtain the graphene / modified titanium dioxide sol composite material,

[0037] According to the present invention, titanium dioxide nano-sol and graphene are firstly provi...

Embodiment 1

[0051] Add 100mL concentrated sulfuric acid to a dry beaker, cool with ice water, add 10g graphite and 10g NaNO while stirring 3 The mixture was stirred rapidly, and 30g KMnO was slowly added after 15min 4 powder, while controlling the temperature below 20°C, to be KMnO 4 After the addition, remove the water bath, strictly control the temperature of the mixture within the range of 35±3°C and continue to stir for 5 hours, slowly add 460mL of deionized water to raise the temperature to 98°C, maintain this temperature for 15min, and dilute to 1400mL with warm water , pour a certain amount of hydrogen peroxide aqueous solution (30%), centrifuge while hot and filter, wash the filter cake with 5% HCl solution, and wash with deionized water until the filtrate is neutral.

[0052] Disperse 0.15g of TTIP and 5mL of oleic acid in toluene, dissolve 0.1mL of tert-butylamine in water, mix the toluene solution of TTIP and oleic acid with the aqueous solution of tert-butylamine in a 50mL re...

Embodiment 2

[0058] Add 100mL concentrated sulfuric acid to a dry beaker, cool with ice water, add a mixture of 10g graphite and 10g NaNO3 while stirring, stir rapidly, and slowly add 30gKMnO after 15min 4 powder, while controlling the temperature below 20°C, to be KMnO 4 After the addition, remove the water bath, strictly control the temperature of the mixture within the range of 35±3°C and continue to stir for 5 hours, slowly add 460mL of deionized water to raise the temperature to 98°C, maintain this temperature for 15min, and dilute to 1400mL with warm water , pour a certain amount of hydrogen peroxide aqueous solution (30%), centrifuge while hot and filter, wash the filter cake with 5% HCl solution, and wash with deionized water until the filtrate is neutral.

[0059] Disperse 0.15g of TTIP and 5mL of oleic acid in toluene, dissolve 0.1mL of tert-butylamine in water, mix the toluene solution of TTIP and oleic acid with the aqueous solution of tert-butylamine in a 50mL reactor, heat to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com