Preparation method for graphene-supported metal nanoparticle compound

A metal nanoparticle, metal-loaded technology, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc. Mild conditions, the effect of reducing the occurrence of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

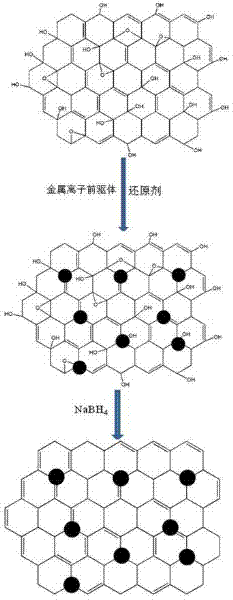

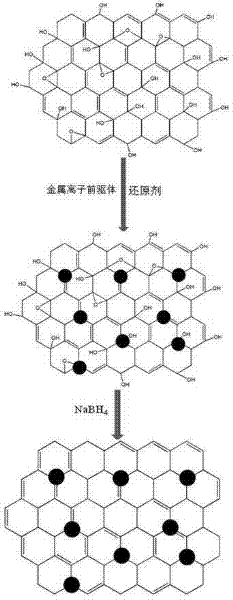

Method used

Image

Examples

Embodiment 1

[0026] (1) washing and purification

[0027] Dissolve 1 mg of graphene oxide into 10 ml of water, ultrasonically disperse and dissolve, then centrifugally wash 3 times with 3% HCl and water at 20,000 rpm, and add deionized water to obtain a uniform 1 mg / ml graphite oxide alkene aqueous solution;

[0028] (2) Synthesis of 3nm gold particles

[0029] 5ml of 0.5mM HAuCl 4 and 5ml of 0.2M cetyltrimethylammonium bromide (CTAB) into a 25ml Erlenmeyer flask, mix well, add 0.6ml of 0.01M NaBH 4 , placed at room temperature for 3 hours;

[0030] (3) Synthesis of graphene oxide-supported 3nm gold particle composite

[0031] Add 1ml of 1mg / ml graphene oxide aqueous solution to the 3nm gold particle solution, mix well, and wash with water for 6 times at 20,000 rpm to obtain the graphene oxide-loaded 3nm gold nanoparticle composite, add 5ml deionized water, and ultrasonically 5 minutes to obtain a homogeneous solution;

[0032] (4) Synthesis of graphene-loaded 3nm gold particle compo...

Embodiment 2

[0036] (1) washing and purification

[0037] Dissolve 1 mg of graphene oxide into 10 ml of water, ultrasonically disperse and dissolve, then wash with 3% HCl and water for 3 times at 20,000 rpm, and add deionized water to obtain a uniform 1 mg / ml graphene oxide aqueous solution;

[0038] (2) Synthesis of 10nm gold particles

[0039] 5ml of 0.5mM HAuCl 4 and 5ml of 0.2M cetyltrimethylammonium bromide (CTAB) into a 25ml Erlenmeyer flask, mix well, add 0.6ml of 0.01M NaBH 4 , placed at room temperature for 3 hours to obtain 3nm gold particles;

[0040] 6ml of 0.5mM HAuCl 4 and 6ml of 0.02M cetyltrimethylammonium chloride (CTAC) into a 25ml Erlenmeyer flask, mix well, then add 4.5ml of 0.1M ascorbic acid (Vc) to the flask, and finally add 0.3ml of 3nm Gold particle seeds, placed at room temperature for 3 hours to obtain 10nm gold particles;

[0041] (3) Synthesis of graphene oxide-supported 10nm gold particle composite

[0042] Add 1ml of 1mg / ml graphene oxide aqueous solu...

Embodiment 3

[0047] (1) washing and purification

[0048] Dissolve 1 mg of graphene oxide into 10 ml of water, ultrasonically disperse and dissolve, then wash with 3% HCl and water for 3 times at 20,000 rpm, and add deionized water to obtain a uniform 0.1 mg / ml graphene oxide aqueous solution;

[0049] (2) Synthesis of graphene oxide platinum nanoparticle composites

[0050] 100ul of 0.01M H2 PtCl 6 Add to 10ml of 0.1mg / ml graphene oxide aqueous solution, mix well, add 1mg of NaBH 4 , placed at room temperature for 3 hours, centrifuged and washed with water for 6 times at 20,000 rpm to obtain a graphene oxide-loaded platinum nanoparticle composite, adding 5ml of deionized water, and ultrasonicating for 5 minutes to obtain a uniform solution;

[0051] (3) Synthesis of graphene-supported platinum nanoparticle composites

[0052] Add 10mg NaBH 4 Put it into the graphene oxide-supported platinum nanoparticle aqueous solution, oscillate evenly, place at room temperature for 2 hours, centrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com