Chitosan silicone-acrylate copolymer composite polrvinyl chloride antibacterial material and preparation method and application thereof

A technology of chitosan and copolymer, which is applied in the field of organic polymer functional materials, can solve problems such as hidden health and safety hazards, contact health and safety hazards, and easy failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

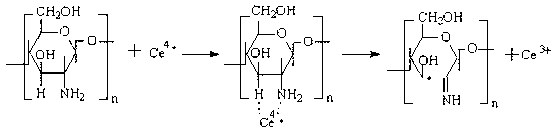

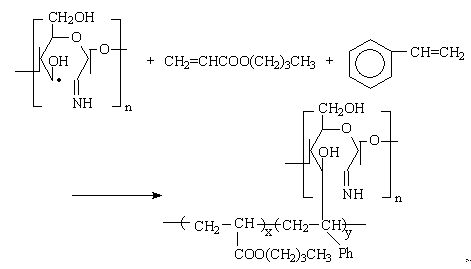

Method used

Image

Examples

example 1

[0037] Preparation of pre-emulsion: Add 0.3kg of sodium dodecylbenzene sulfonate and 15kg of ionized water into the reactor. The reactor is equipped with a stirrer, a condensing device, and a heating jacket, and the temperature of the reactor rises to 38°C , after stirring to dissolve the surfactant, add 0.05kg of OP-10 and continue stirring for 10 minutes. 12 kg of distilled acrylonitrile, 8 kg of isoprene, 4 kg of butyl acrylate, 1 kg of hydroxyethyl acrylate, and 1.8 kg of methyl methacrylate were added dropwise in sequence, and the dropping time was about 30 minutes. After the addition, stir for another 30 minutes, cool at room temperature, and set aside for later use.

[0038] Preparation of chitosan dispersion sol: Chitosan powder 1.5kg, water 8kg, acrylic acid 0.5kg, use vertical planetary stirring device, under high-speed mixing state, disperse chitosan in acrylic acid aqueous solution to make chitosan Disperse the sol with sugar and set aside for later use. System t...

example 2

[0051] Implementation steps are identical with implementation method and preparation example 1. The different processes are:

[0052] The monomer composition in the process of "preparation of pre-emulsion" is: 6 kg of acrylonitrile, 8 kg of isoprene, 3 kg of butyl acrylate, 1.8 kg of hydroxyethyl acrylate, and 1.2 kg of methyl methacrylate.

[0053] In the "blending powder preparation" process: the ingredients of the blending powder are composed of: 4 kg of chitosan silicon acrylic copolymer, 25 kg of polyvinyl chloride, 1 kg of 8813 organotin heat stabilizer, 0.2 kg of stearic acid, polyvinyl chloride Ethylene wax 0.15kg, precipitated calcium carbonate 2 kg

[0054] The main performance indicators of the product: the antibacterial rate of the antibacterial (Escherichia coli) performance of the plastic sheet produced is over 95%, the mold growth grade of the antifungal performance is less than 1, the tensile strength of the material is 58MPa, and the notched impact strength i...

example 3

[0056] Implementation steps are identical with implementation method and preparation example 1. The different processes are:

[0057] The monomer composition in the "pre-emulsion preparation" process is: 8 kg of acrylonitrile, 10 kg of isoprene, 5 kg of butyl acrylate, 2 kg of methyl methacrylate, and 1.8 kg of hydroxyethyl acrylate.

[0058] In the "blending powder preparation" process: the batching of the blending powder consists of: chitosan silicon acrylic copolymer 5 kg, polyvinyl chloride 25 kg, 8813 organotin heat stabilizer 1kg, stearic acid 0.2kg, polyvinyl chloride Ethylene wax 0.15 kg, precipitated calcium carbonate 5 kg.

[0059] The main performance indicators of the product: the antibacterial rate of the antibacterial (Escherichia coli) performance of the plastic sheet produced is over 95%, the mold growth grade of the antifungal performance is less than 1 grade, the tensile strength of the material is 52MPa, and the notched impact strength is 49KJ / m 2 , Vic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com