Method for preparing lactoferricin and method for applying lactoferricin in bacterial inhibition of foods

A technology of bovine lactoferrin peptide and fusion protein, which is applied in the preparation of lactoferrin peptide and its application in food bacteriostasis, and can solve the problem of recombinant expression bovine lactoferrin peptide and recombinant bovine lactoferrin peptide not involving Escherichia coli. problem, to achieve good inhibition effect, simple method and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of lactoferrin peptide:

[0035] (i) Activation of genetically engineered bacteria: use an inoculation loop to inoculate a loop of genetically engineered bacteria in 5 mL of LB liquid medium containing kanamycin sulfate after activation, then inoculate in the fermentation medium at a ratio of 1.5% (v / v) Medium fermentation, 7 hours after lactose induction;

[0036] Among them, the fermentation medium is: soluble starch 7g / L, beef extract 30g / L, sodium chloride 6.7g / L

[0037] (ii) Bacterial lysis: Add about 80 mL of lysis buffer to 20 g of induced cells, mix well and incubate overnight at 37°C, centrifuge to remove the supernatant (8000 r / min, 20 min), add an equal volume of inclusion body washing buffer, 37 After incubating at ℃ for 2-3 hours, centrifuge to remove the supernatant (8000r / min, 20min);

[0038] Wherein, the cell lysis buffer is: lysozyme (Lysozyme), its mass percentage is 0.02%, polyethanol octyl phenyl ether (Triton X-100), its v...

Embodiment 2

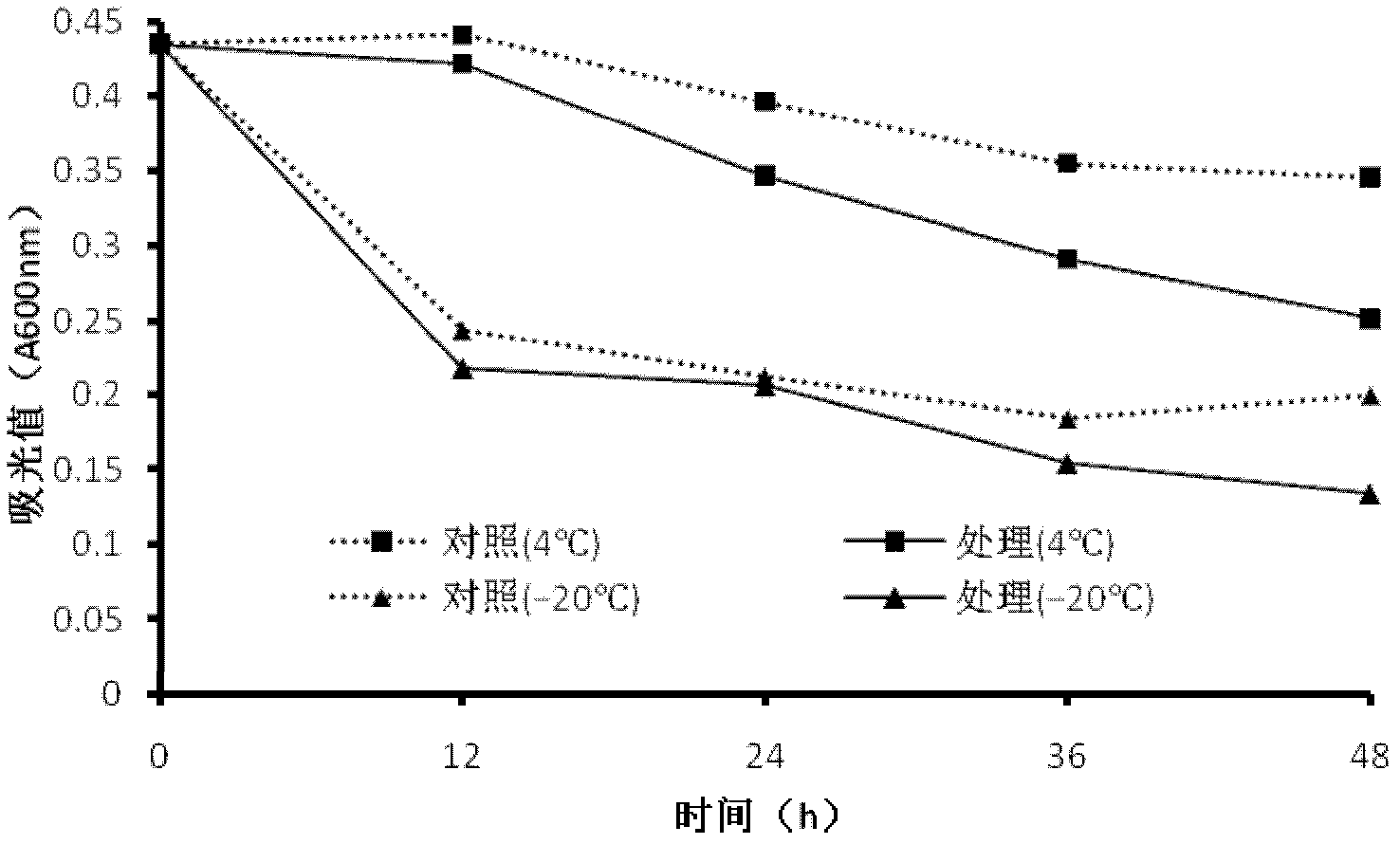

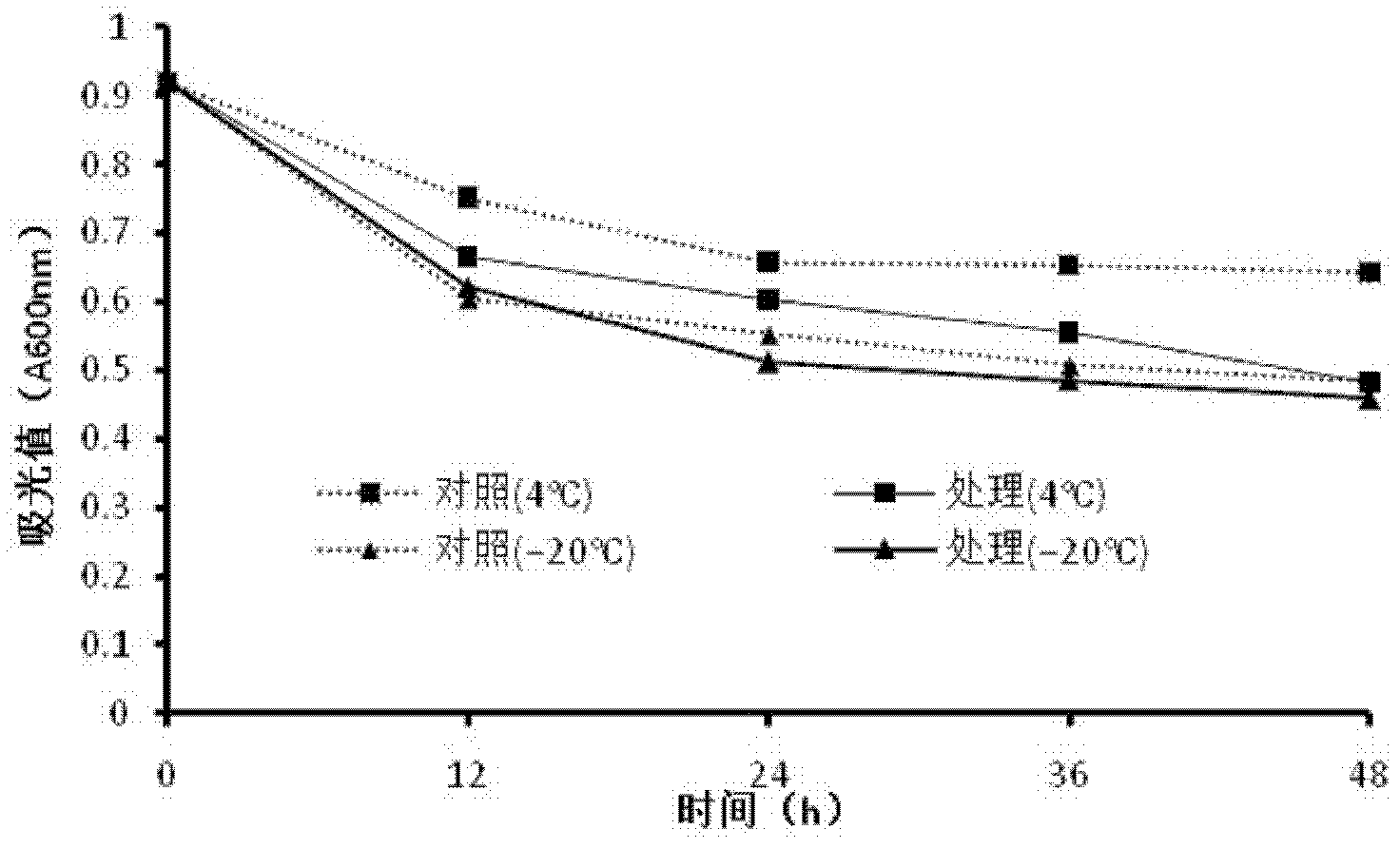

[0045] Put 25g of arctic shellfish inoculated with Vibrio parahaemolyticus into 225mL of bacteriostatic solution [bovine lactoferrin peptide isolated in Example 1: 2000μg / mL] for 30 minutes, store it at a low temperature of 4°C for 3 days, and measure it by the national standard method Vibrio parahaemolyticus and the total number of bacteria, and normal saline as a blank control. The results showed that compared with the control group, the content of Vibrio parahaemolyticus in arctic shellfish treated with antibacterial solution was reduced by 4.1×10 5 CFU / g.

Embodiment 3

[0047] Put 25g of arctic shellfish inoculated with Vibrio parahaemolyticus into 225mL of bacteriostatic solution [concentration of bovine lactoferrin peptide isolated in Example 1: 3000 μg / mL] for 30 minutes, then store at low temperature 4°C for 3 days, using the national standard method The total number of Vibrio parahaemolyticus and bacteria was determined, and normal saline was used as a blank control. The results showed that compared with the control group, the content of Vibrio parahaemolyticus in arctic shellfish treated with antibacterial solution was reduced by 5.1×10 5 CFU / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com