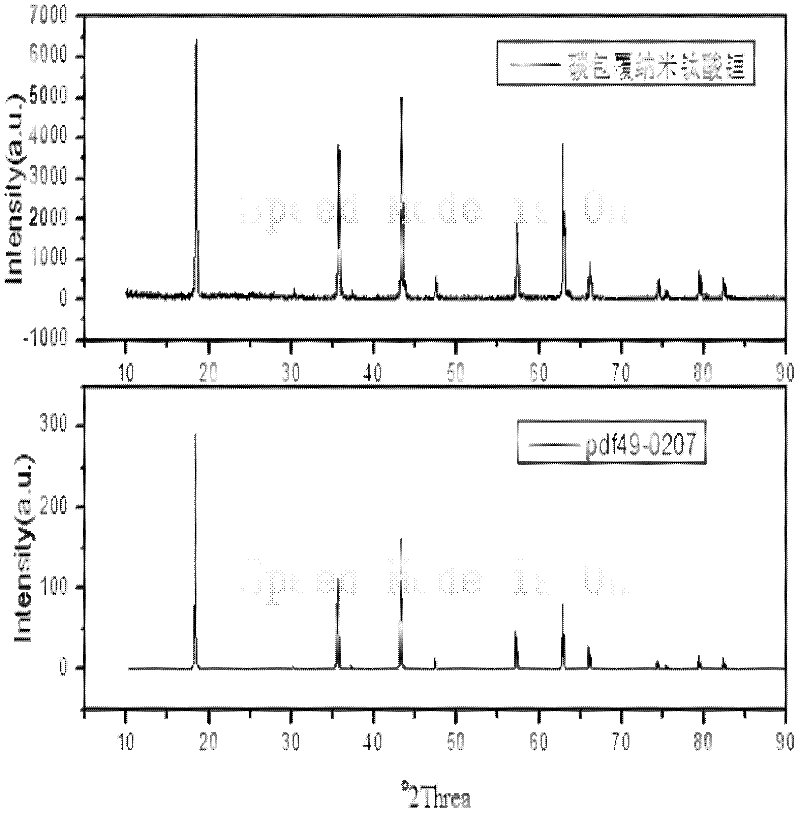

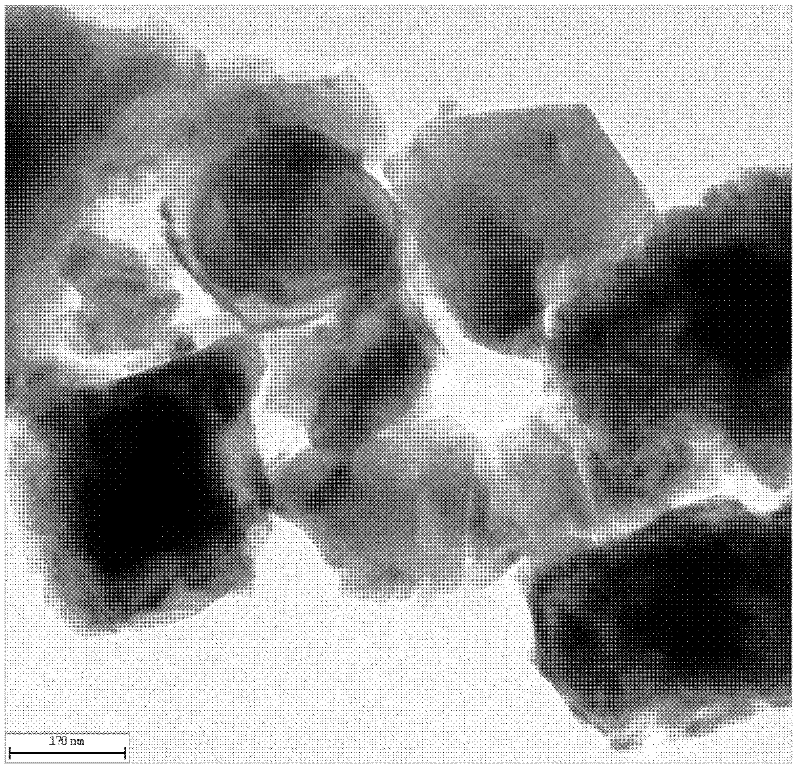

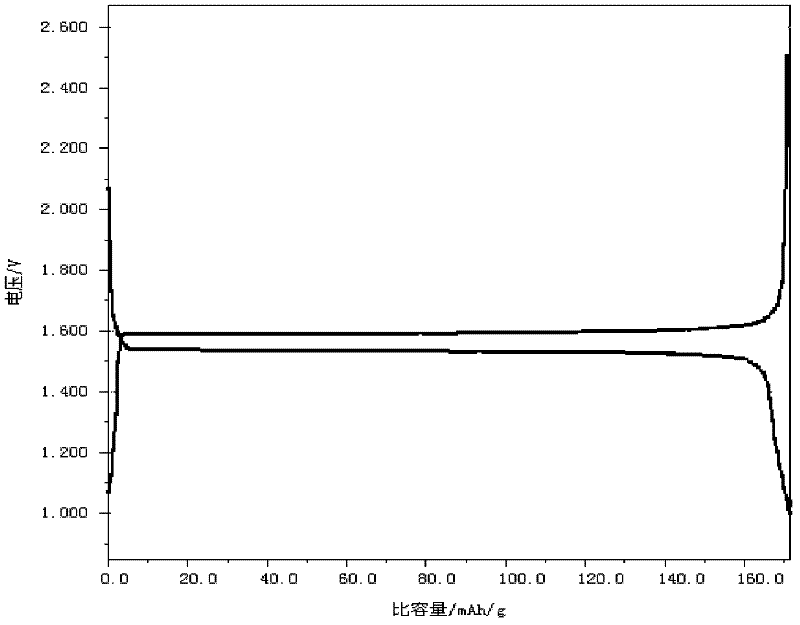

Method for preparing carbon-coated nano lithium titanate by rheological phase reaction

A nano-lithium titanate and carbon coating technology, applied in nano-carbon, nano-technology, nano-technology and other directions, can solve the problems of poor material rate performance, and achieve the effects of good rate performance, low synthesis temperature and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] a. Weigh Li according to the molar ratio of lithium and titanium elements of 0.84:1 2 CO 3 and anatase TiO 2 , and added 2wt% of PVB (2% of the mass of theoretically synthesized lithium titanate), ball milled in a mixing tank at a speed of 400 rpm for 6 hours.

[0024] b. Add an appropriate amount of absolute ethanol solvent, stir slowly, adjust the mixture to a colloidal rheological state, and then dry it in a vacuum oven at 80° C. for 6-12 hours to obtain a precursor.

[0025] c. Place the precursor in a tube furnace, program the temperature in a nitrogen atmosphere, raise the temperature to 900°C at 5°C / min, keep it for 12 hours, and cool it down to room temperature naturally to obtain a carbon-coated nano-lithium titanate material.

Embodiment 2

[0027] a. Weigh Li according to the molar ratio of lithium and titanium elements of 0.83:1 2 CO 3 and anatase TiO 2 , and added 6wt% PVB (6% of the mass of theoretically synthesized lithium titanate), ball milled in a mixing tank at a speed of 400 rpm for 8 hours.

[0028] b. Add an appropriate amount of absolute ethanol solvent, stir slowly, adjust the mixture to a colloidal rheological state, and then dry it in a vacuum oven at 80° C. for 6-12 hours to obtain a precursor.

[0029] c. Place the precursor in a tube furnace, program the temperature in a nitrogen atmosphere, raise the temperature to 850°C at 5°C / min, keep it for 14 hours, and cool it down to room temperature naturally to obtain a carbon-coated nano-lithium titanate material.

Embodiment 3

[0031] a. Weigh Li according to the molar ratio of lithium and titanium elements of 0.85:1 2 CO 3 and anatase TiO 2 , and added 10wt% PVB (10% of the theoretically synthesized lithium titanate mass), ball milled in a mixing tank at a speed of 400 rpm for 8 hours.

[0032] b. Add an appropriate amount of absolute ethanol solvent, stir slowly, adjust the mixture to a colloidal rheological state, and then dry it in a vacuum oven at 80° C. for 6-12 hours to obtain a precursor.

[0033] c. Put the precursor in a tube furnace, program the temperature in a nitrogen atmosphere, raise the temperature to 800°C at 5°C / min, keep it warm for 16 hours, and cool it down to room temperature naturally to obtain a carbon-coated nano-lithium titanate material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com