Preparation method of nickel ferrite spinel nano-powder

A technology of spinel and nanopowder, which is applied in the direction of nanotechnology, chemical instruments and methods, iron compounds, etc., can solve the problems of harsh conditions, difficult control, high cost, etc., and achieve easy operation and control, high selectivity, and less pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The inorganic iron salt used is FeSO 4 ·7H 2 O;

[0023] The inorganic nickel salt used is NiSO 4 ·6H 2 O;

[0024] Mix inorganic iron salt, inorganic nickel salt and NaOH and physically break it into powder, the mixing ratio is according to Fe 2+ 、Ni 2+ and OH - The molar ratio is 2:1:6;

[0025] Put the dispersant NaCl and the powder into the grinder for grinding. NaCl accounts for 20% of the total weight of the powder. When the ground material turns brown, dry the ground material at 100±5°C 6h, obtain the precursor of tan block;

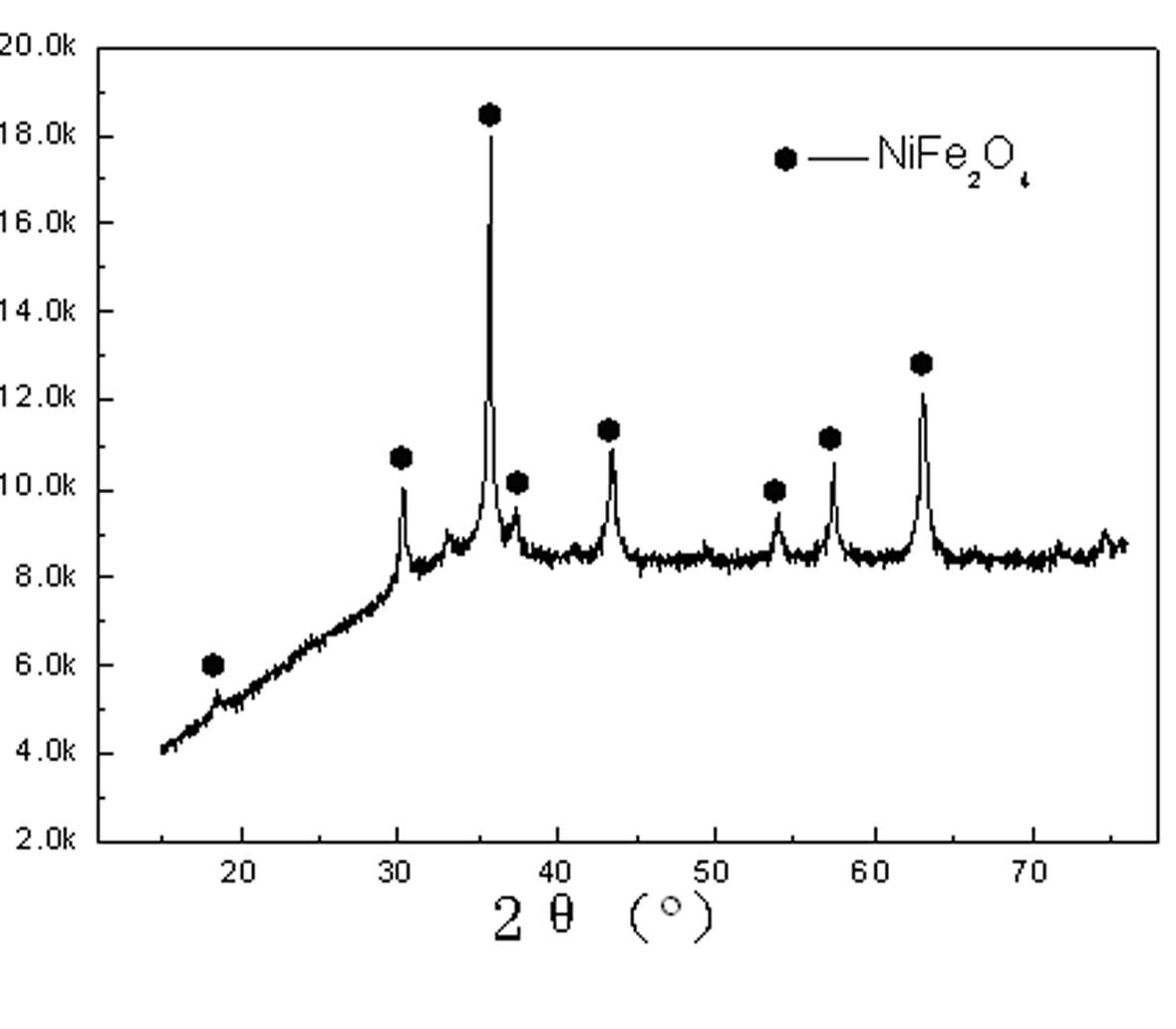

[0026] The precursor was calcined at 800°C for 60 minutes, washed with water to remove impurities, and then dried to remove water to obtain nickel ferrite spinel nanopowder; the obtained product was detected by X-ray diffraction (XRD), and the results were as follows figure 1 As shown, the diffraction peaks are all characteristic peaks of nickel ferrite, and the average grain size calculated by the Debye-Scherrer formula is 28nm; t...

Embodiment 2

[0028] The inorganic iron salt used is FeCl 2 4H 2 O;

[0029] The inorganic nickel salt used is NiCl 2 ·6H 2 O;

[0030] Mix inorganic iron salt, inorganic nickel salt and NaOH and physically break it into powder, the mixing ratio is according to Fe 2+ 、Ni 2+ and OH - The molar ratio is 2:1:6;

[0031] Put the dispersant NaCl and the powder into the grinder for grinding. NaCl accounts for 21% of the total weight of the powder. When the ground material turns brown, dry the ground material at 100±5°C 7h, obtain the precursor of tan block;

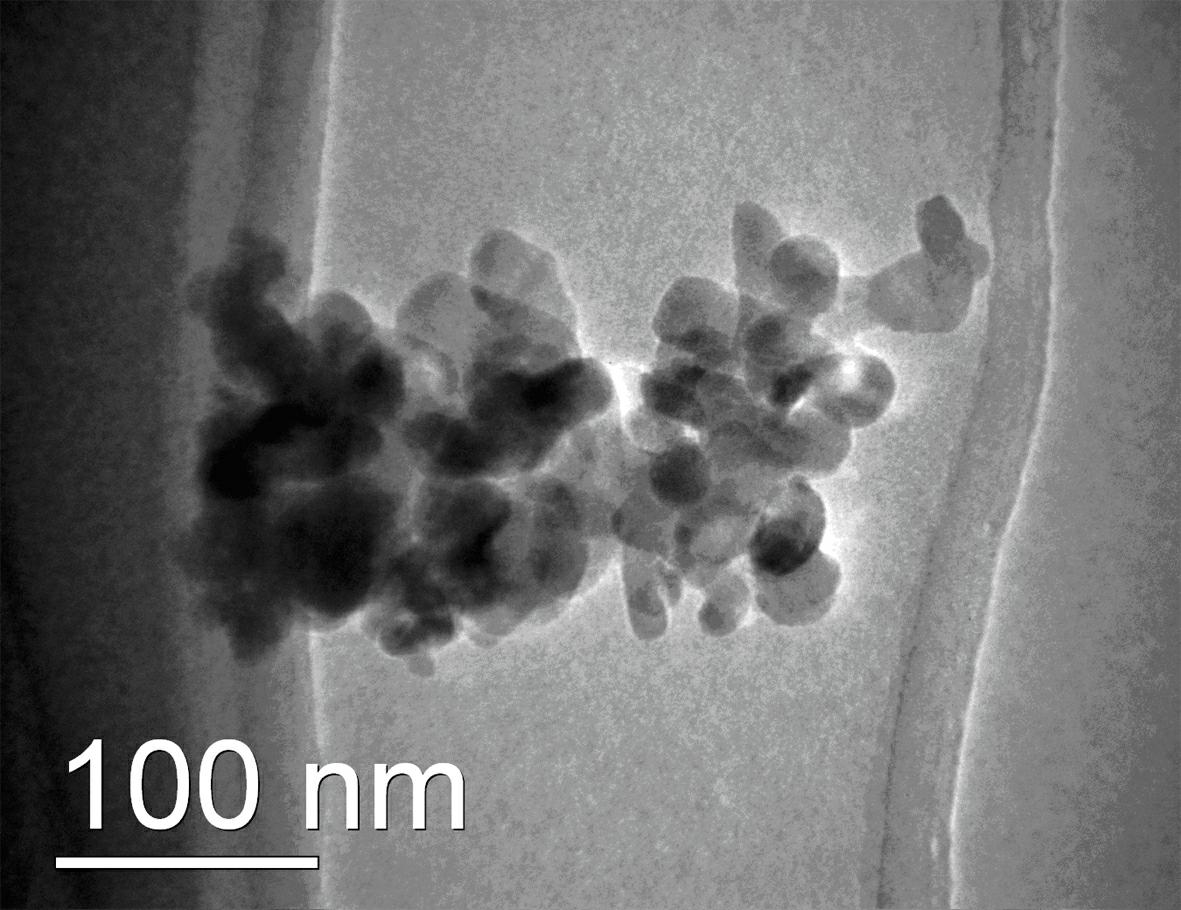

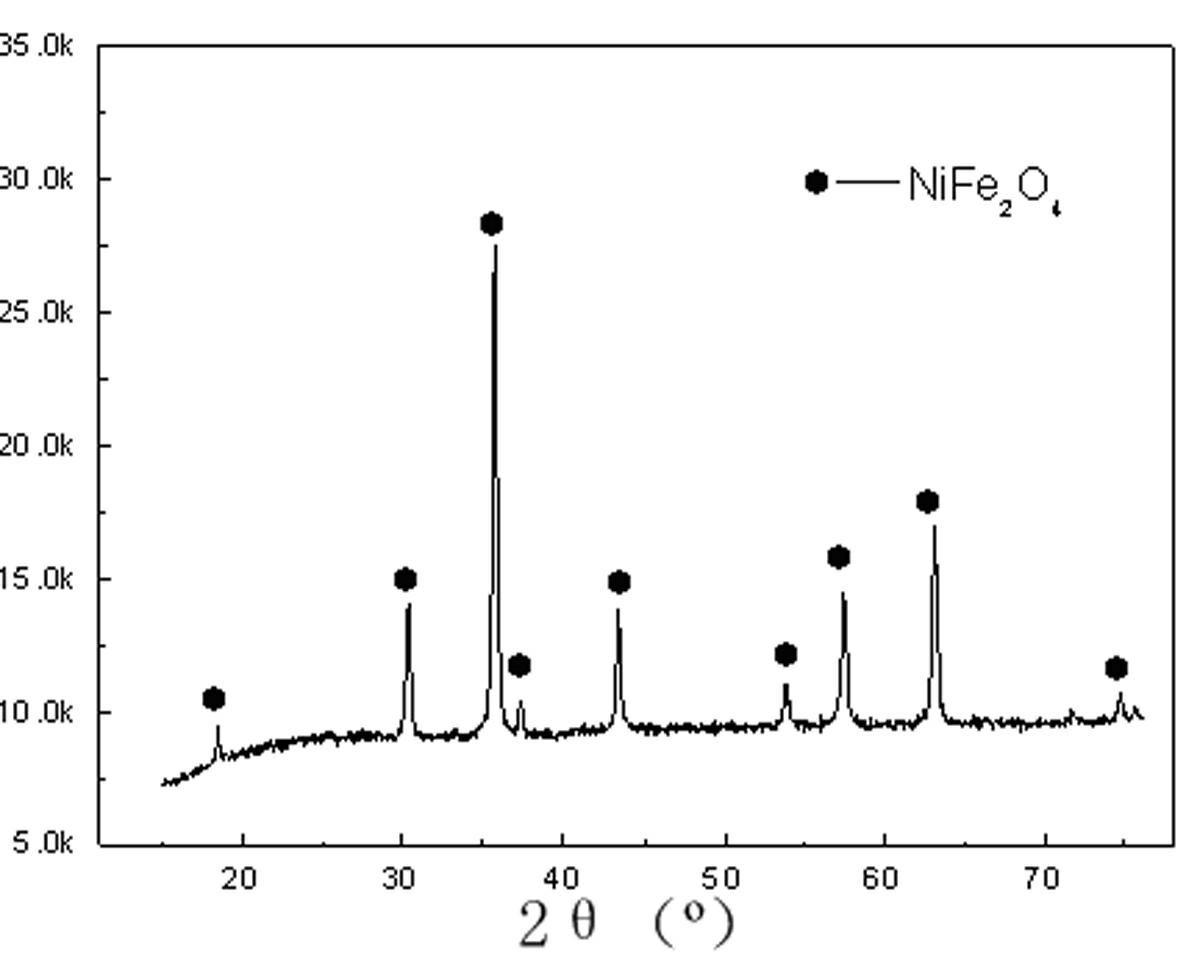

[0032] The precursor was calcined at 700°C for 80 minutes, washed with water to remove impurities, and nickel ferrite spinel nanopowder was obtained; the obtained product was detected by X-ray diffraction (XRD), and the results were as follows image 3 As shown, the diffraction peaks are all characteristic peaks of nickel ferrite, and the average grain size calculated by the Debye-Scherrer formula is 41nm; the obtained product is de...

Embodiment 3

[0034] The inorganic iron salt used is FeSO 4 ·7H 2 O;

[0035] The inorganic nickel salt used is NiCO 3 3Ni(OH) 2 .4H 2 O;

[0036] Mix inorganic iron salt, inorganic nickel salt and NaOH and physically break it into powder, the mixing ratio is according to Fe 2+ 、Ni 2+ and OH - The molar ratio is 2:1:6;

[0037] Put the dispersant NaCl and the powder into the grinder for grinding. NaCl accounts for 22% of the total weight of the powder. When the ground material turns brown, dry the ground material at 100±5°C 8h, obtain the precursor of tan block;

[0038] The precursor was calcined at 750°C for 70 minutes, washed with water to remove impurities, and then dried to remove water to obtain nickel ferrite spinel nanopowder; the particle size was 20-40nm, with an average particle size of 35nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com