Preparation method for silicon carbide preform based on water-based adhesive

A technology of water-based binder and prefabricated parts, which is applied in the field of electronic packaging metal matrix composite materials, can solve the problems of high sintering temperature, poor fluidity of granulated powder, and low strength of prefabricated parts, and achieve high opening porosity and sintering Low temperature and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

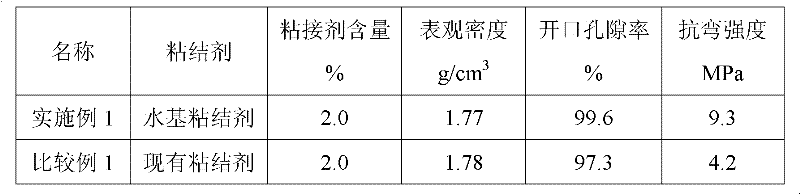

Embodiment 1

[0028] Example 1: Weigh 3000 g of silicon carbide particles A (produced by Shandong Kaihua Silicon Carbide Powder Co., Ltd.: W63, average particle size: 55 μm) and an aluminum dihydrogen phosphate solution with a solid content of 40 wt % (Zhongtian Phosphate, Zhuzhou, Hunan) Chemical Co., Ltd.) 150g and 30wt% paraffin emulsion (Dongguan Aoda Chemical Co., Ltd.) 210g and deionized water 300g; silicon carbide particles are heated to 50°C for about 10 minutes while stirring in a kneader, and dihydrogen phosphate Aluminum, paraffin emulsion and deionized water are fully stirred in a water bath at a constant temperature of 50°C and preheated for about 10 minutes, then slowly add the water-based binder to the silicon carbide particles being stirred, open the cylinder cover, and set the heating temperature of the kneader Stir and mix at 50°C; when the moisture content meter measures the moisture content of the mixture to be 4.2%, put the mixture into a tray with a thickness of 3 mm to...

Embodiment 2

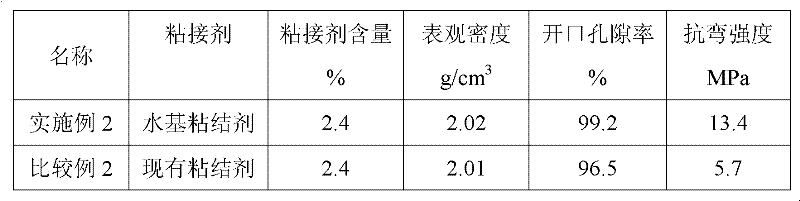

[0035]Example 2: Weigh 2100 g of silicon carbide particles A (produced by Shandong Kaihua Silicon Carbide Micro Powder Co., Ltd.: W63, average particle size: 55 μm) and silicon carbide particles B (produced by Shandong Kaihua Silicon Carbide Micro Powder Co., Ltd.: W14, average particle size Diameter: 12μm) 900g, solid content is 40wt% aluminum dihydrogen phosphate solution (Hunan Zhuzhou Zhongtian Phosphate Chemical Co., Ltd.) 180g and 30wt% paraffin emulsion (Dongguan Aoda Chemical Co., Ltd.) 240g and deionized water 180g; the silicon carbide particles are heated in a kneader to 60°C for about 10 minutes while stirring in a kneader, and the aluminum dihydrogen phosphate, paraffin emulsion and deionized water are fully stirred in a water bath at a constant temperature of 60°C for about 10 minutes to preheat, and then Slowly add the water-based binder to the silicon carbide particles being stirred, open the cylinder head, and set the heating temperature of the kneader to 60°C f...

Embodiment 3

[0042] Example 3: Weigh 1500g of silicon carbide particles A (produced by Shandong Kaihua Silicon Carbide Micropowder Co., Ltd.: 100 mesh, average particle size: 135 μm), and silicon carbide particles B (produced by Shandong Kaihua Silicon Carbide Micropowder Co., Ltd.: W40, average Particle size: 28μm) 600g, silicon carbide particle C (produced by Shandong Kaihua Silicon Carbide Powder Co., Ltd.: W14, average particle size: 12μm) 300g and silicon carbide particle D (produced by Shandong Kaihua Silicon Carbide Powder Co., Ltd.: W5, average Particle size: 3.5 μm) 600g, solid content is 40wt% aluminum dihydrogen phosphate solution (Hunan Zhuzhou Zhongtian Phosphate Chemical Co., Ltd.) 210g and 30wt% paraffin emulsion (Dongguan Aoda Chemical Co., Ltd.) 300g and remove 300g of ionized water; heat the silicon carbide particles to 70°C for about 10 minutes while stirring in the kneader, and preheat for about 10 minutes at a constant temperature of 60°C for about 10 minutes. Then slo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com