Detection method for peroxide value of milk powder

A peroxide value and detection method technology, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, can solve problems such as poor reproducibility and inappropriateness. Achieve good reproducibility and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

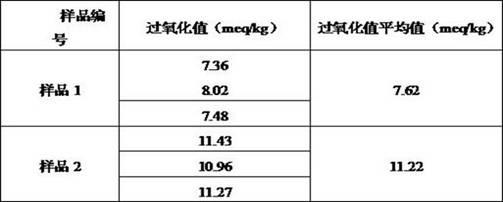

Examples

Embodiment 1

[0041] The milk powder peroxide value detection method embodiment of the present invention comprises the following steps:

[0042] Reagent and material preparation:

[0043] 1) Ethanol; 2) Diethyl ether; 3) Sodium chloride solution; 4) Anhydrous sodium sulfate; 5) Fat dissolving mixture: chloroform: glacial acetic acid mixture = 2:3; 6) Potassium iodide saturated solution: weigh Dissolve 14g of potassium iodide in 10mL of water, heat slightly if necessary, and store in a brown bottle after cooling; 7) 0.5% starch indicator: Weigh 1g of starch and dissolve it in 10mL of water, pour it into a 250mL flask, add water to 200mL , boiled into a solution, and kept stirring until the liquid was transparent, and stored in the refrigerator; 8) Sodium thiosulfate standard solution [c (Na 2 S 2 o 3 ) = 0.1mol / L]; 24.9g anhydrous sodium thiosulfate (Na 2 S 2 o 3 ·5H 2 O) Dissolve in distilled water and dilute to 1L; before use, dilute to sodium thiosulfate standard solution [c(Na 2 ...

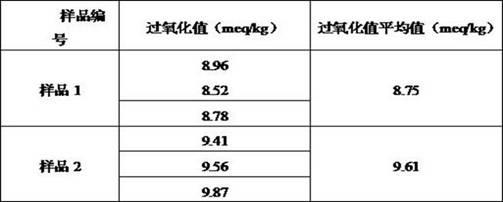

Embodiment 2

[0063] The milk powder peroxide value detection method embodiment of the present invention comprises the following steps:

[0064] Reagent and material preparation:

[0065] 1) Fat dissolving mixture: isooctane: glacial acetic acid mixture = 2:3; other materials are the same as in Example 1.

[0066] Detection operation steps:

[0067] (1) Sample processing

[0068] Weigh 30g sample, put it into a 500mL Erlenmeyer flask, add 100mL 55°C distilled water, mix well, and cool to room temperature;

[0069] (2) Preparation of measurement solution

[0070] 1) Add 100mL of ethanol to the above-treated sample solution, shake it, then add 100mL of ether, let it stand for 15 minutes, and pour it into a separatory funnel;

[0071] 2) If the organic layer is not clear, add 55mL saturated sodium chloride solution, let it stand for 10 minutes, separate the liquid, and keep the organic layer;

[0072] 3) Wash the organic layer with 100mL water and shake it. During the shaking process, pay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com