Injectable compound bone cement and preparation method thereof

A technology of bone cement and calcium phosphate bone cement, applied in the field of injectable composite bone cement kit, injectable composite bone cement and its preparation, to achieve the effects of high compressive strength, excellent anti-collapse performance and excellent injection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

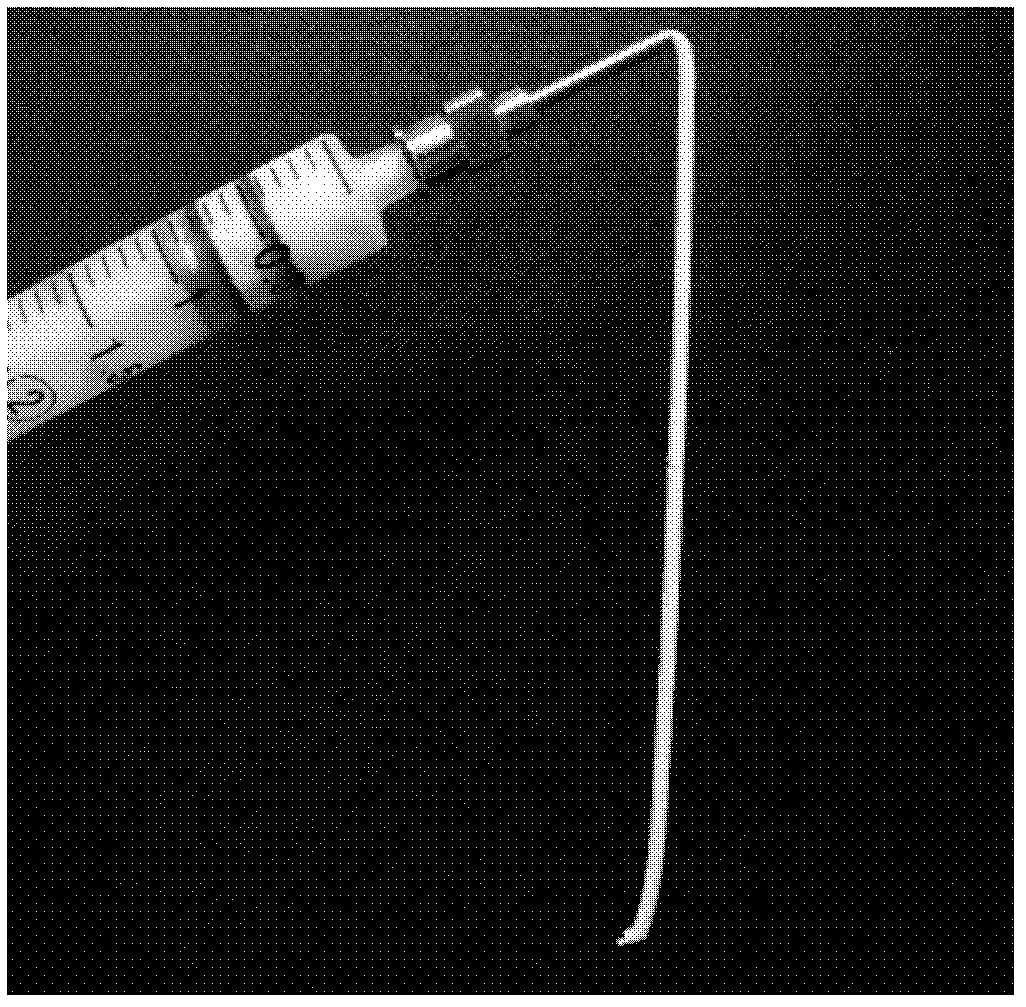

[0113] Preparation method of injectable composite bone cement

[0114] In a preferred embodiment, the preparation method of the injectable composite bone cement provided by the present invention comprises the following steps:

[0115] (1) Chitosan microspheres and calcium phosphate bone cement powder are mixed evenly;

[0116] (2) Add a solidifying solution containing sodium glycerophosphate (GP), and mix evenly to obtain an injectable composite bone cement.

[0117] In a preferred embodiment, the preparation method of the injectable composite bone cement provided by the present invention comprises the following steps:

[0118] (1) chitosan microspheres are mixed evenly with the solidified solution containing sodium glycerophosphate,

[0119] (2) Add calcium phosphate bone cement powder and mix evenly to obtain an injectable composite bone cement.

[0120] In another preferred example, the weight ratio of the calcium phosphate bone cement powder to the cross-linked chitosan...

Embodiment 1

[0131] Preparation of sulfuric acid cross-linked chitosan

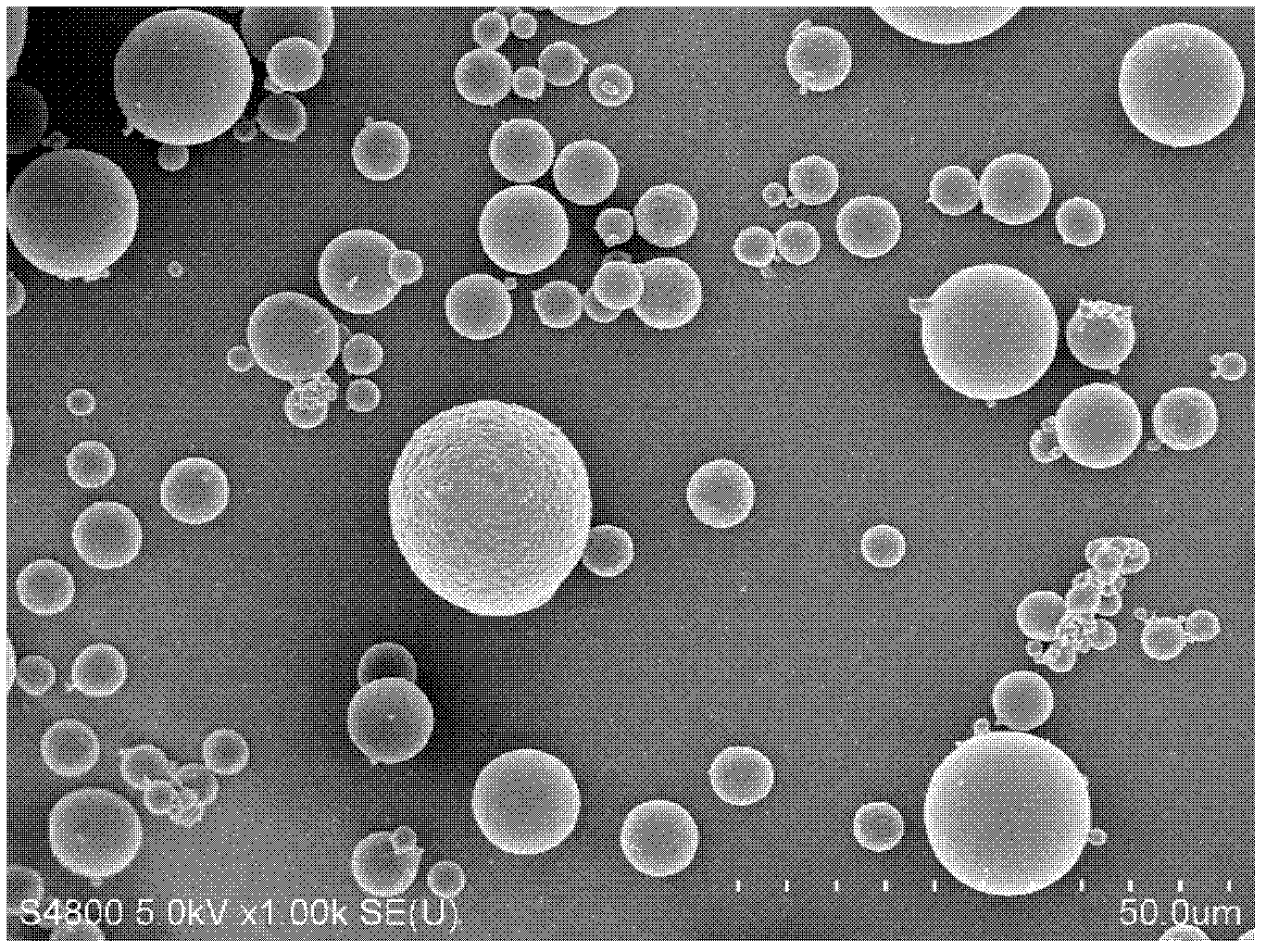

[0132] Dissolve chitosan in acetic acid solution, prepare 3% (w / v) chitosan solution, add slowly in the oil phase liquid paraffin containing emulsifier, stir to form W / O emulsion, add 20% (w / v) v) Sulfuric acid solution is cross-linked to form sulfuric acid cross-linked chitosan microspheres, then fully washed with acetone, absolute ethanol and water, and freeze-dried to obtain chitosan microspheres with complete morphology and smooth and compact surface (Such as figure 1 shown), the particle size is 5-20 μm.

Embodiment 2

[0134] Preparation of phosphoric acid cross-linked chitosan

[0135] Dissolve chitosan in acetic acid solution, prepare 1% (w / v) chitosan solution, and drop it into NaOH-methanol mixed solution under high-voltage static electricity to coagulate, collect microspheres, and then disperse the microspheres Treat in a phosphoric acid solution with a concentration of 30% (w / v) for 20 hours; collect the microspheres, wash and dry them fully to obtain phosphoric acid cross-linked chitosan microspheres, and the particle size of the microspheres is 80-120 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com