Compound microbial fertilizer and method for producing same

A technology of composite microorganisms and microbial agents, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of restricting the development of microbial fertilizers, insufficient production technology innovation, and low microbial fertilizers, so as to improve soil physical and chemical properties and lower product prices , the effect of large market space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

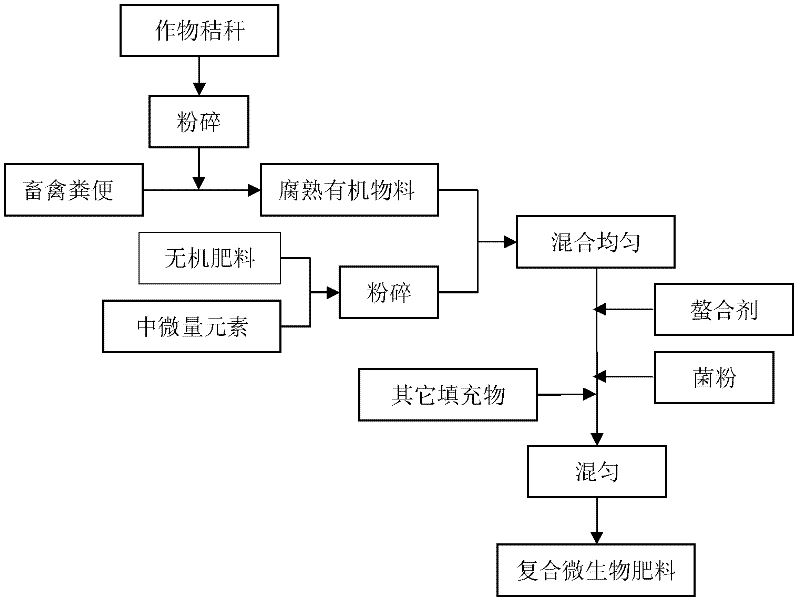

Method used

Image

Examples

Embodiment 1

[0040] The decomposing of embodiment 1 organic fertilizer

[0041] (1) 500 kg of corn stalks and corncobs are pulverized into 50-60 mesh powder;

[0042] (2) Spread a layer of sludge with a thickness of 20cm on the ventilation ditch of the accumulation yard as a bottom pad for absorbing infiltrating fertilizer;

[0043] (3) Put pig manure and decomposing agent (effective number of viable bacteria ≥ 2.0×10 10cfu / g enzyme bacteria, add 1-3kg per ton), crop straw powder, attapulgite, mix well, pile up layer by layer, make sure, and sprinkle manure and water on each layer, and then sprinkle evenly A small amount of lime and phosphate rock powder are added, and the thickness of each layer is generally 15-25cm until it reaches a height of 1.2-1.5m. The upper layer should be thin, and the middle and lower layers should be slightly thicker. The maximum water holding capacity of the compost material is 60-75%, the carbon-nitrogen ratio is controlled at 25:1, and the pH value is contr...

Embodiment 2

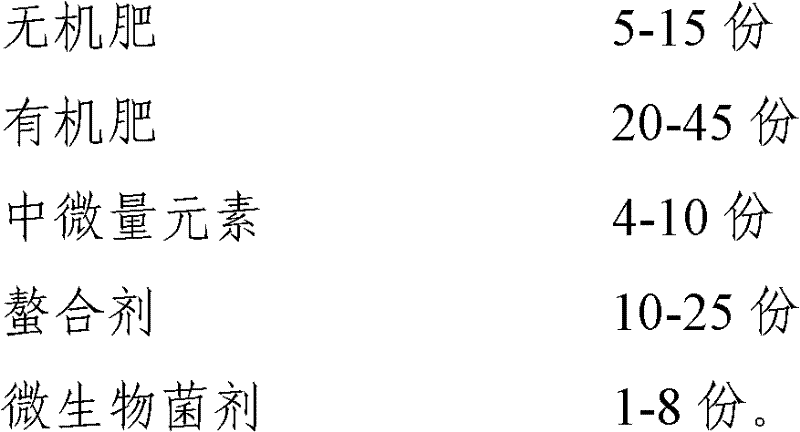

[0046] The preparation of embodiment 2 compound microbial fertilizers

[0047] Prepare 100kg of compound microbial fertilizers according to the following weight ratio: 12 parts of inorganic fertilizers, 35 parts of organic fertilizers, 8 parts of medium and trace elements, 20 parts of chelating agents, 5 parts of microbial bacterial agents, and 20 parts of fillers.

[0048] The composition ratio of the inorganic fertilizer is urea 4: ammonium sulfate 1: diammonium phosphate 2.5: calcium magnesium phosphate fertilizer 2: potassium sulfate 2.5;

[0049] The organic fertilizer is decomposed from pig manure, corn stalks, wheat stalks, and cotton stalks, and the mass ratio of each component is 9:1:1:1;

[0050] The composition ratio of the trace element raw materials is ammonium molybdate 1: borax 2: copper sulfate 2: zinc sulfate 3;

[0051] Described chelating agent is fulvic acid, needs to carry out necessary ammonification treatment according to the routine technique in this f...

Embodiment 3

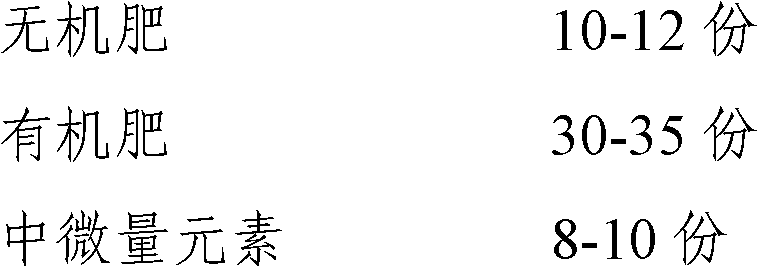

[0058] The preparation of embodiment 3 compound microbial fertilizers

[0059] Prepare 100kg compound microbial fertilizer according to following weight ratio: 10 parts of inorganic fertilizers, 32 parts of organic fertilizers, 10 parts of medium and trace elements, 25 parts of chelating agents, 6 parts of microbial bacterial agents, 17 parts of fillers.

[0060] The composition ratio of the inorganic fertilizer is urea 3: diammonium phosphate 1.5: ammonium bicarbonate 1.5: calcium magnesium phosphate fertilizer 2: potassium sulfate 2;

[0061] The composition ratio of the organic fertilizer is obtained from decomposing pig manure, corn stalks and wheat stalks, and the mass ratio of each component is 9:2:1;

[0062] The composition ratio of the medium and trace element raw materials is ammonium molybdate 1: borax 2.5: magnesium sulfate 3.5: ferrous sulfate 3;

[0063] Described chelating agent is fulvic acid, needs to carry out necessary ammonification treatment according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com