Environmentally-friendly method for preparing chitosan quaternary ammonium salt in ion liquid

A technology of chitosan quaternary ammonium salt and ionic liquid is applied in the field of quaternization and modification of chitosan, and achieves the effects of reducing production cost, simple preparation process and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

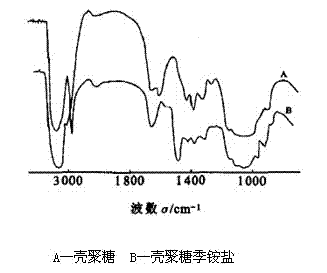

[0018] In a three-necked reaction flask with a stirring device, dissolve 1 g of chitosan powder in 100 ml of a 0.5% glycine ionic liquid aqueous solution, stir until the chitosan is completely dissolved, seal it, and place it at room temperature overnight for later use; Slowly add 50% glycidyl trimethyl ammonium chloride solution dropwise in the sugar ionic liquid solution so that the mass ratio of chitosan and glycidyl trimethyl ammonium chloride is 1:2. ℃, react for 5 hours; after the reaction, add 3 times the volume of acetone to the reaction solution, and white insoluble matter is precipitated, the precipitate is washed 3 times with acetone, and vacuum-dried at 40 ℃ to constant weight to obtain white chitosan quaternary ammonium salt solid powder , the measured solubility is 6.7%, and the degree of substitution is 109.9%. The resulting product is found through infrared spectrum analysis, at 1030cm -1 and 1074cm -1 Nearby, the C-O stretching vibration absorption peaks of...

Embodiment 2

[0020] In a three-necked reaction flask with a stirring device, dissolve 1g of chitosan powder in 100ml of a 1% glycine ionic liquid aqueous solution, stir until the chitosan is completely dissolved, seal it, place it at room temperature overnight, and set aside; Slowly add 50% glycidyl trimethyl ammonium chloride solution dropwise in the sugar ionic liquid solution, so that the mass ratio of chitosan and glycidyl trimethyl ammonium chloride is 1:1. ℃, react for 5 hours; after the reaction, add 3 times the volume of acetone to the reaction solution, and white insoluble matter is precipitated, the precipitate is washed 3 times with acetone, and vacuum-dried at 40 ℃ to constant weight to obtain white chitosan quaternary ammonium salt solid powder , the measured solubility is 5.5%, and the degree of substitution is 92.6%.

Embodiment 3

[0022] In a three-necked reaction flask with a stirring device, dissolve 1 g of chitosan powder in 100 ml of a 2% glycine ionic liquid aqueous solution, stir until the chitosan is completely dissolved, seal it, and place it at room temperature overnight for later use; Slowly add 50% glycidyl trimethyl ammonium chloride solution dropwise in the sugar ionic liquid solution so that the mass ratio of chitosan and glycidyl trimethyl ammonium chloride is 1:2. ℃, react for 5 hours; after the reaction, add 3 times the volume of acetone to the reaction solution, and white insoluble matter is precipitated, the precipitate is washed 3 times with acetone, and vacuum-dried at 40 ℃ to constant weight to obtain white chitosan quaternary ammonium salt solid powder , the measured solubility was 6.5%, and the degree of substitution was 105.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com