Preparation method of quaternized chitosan anion hybrid membrane doped with positive polystyrene latex

A technology of quaternized chitosan and polystyrene emulsion, applied in electrochemical generators, fuel cell parts, circuits, etc., can solve the problem of increasing methanol permeability, decreasing membrane electrolyte conductivity, and low conductivity and other problems, to achieve the effect of increasing the ion exchange capacity and electrical conductivity, and reducing the methanol permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

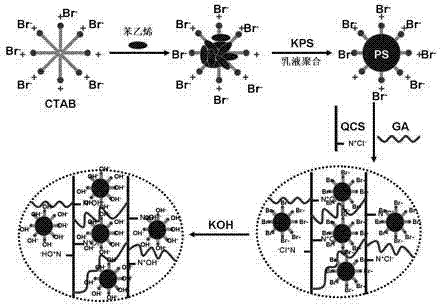

Method used

Image

Examples

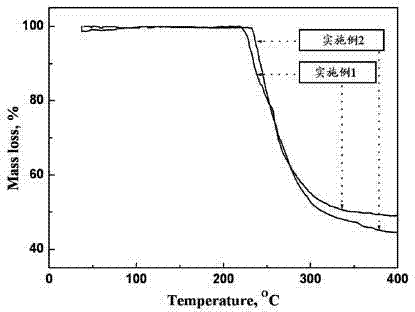

Embodiment 1

[0030] (1) Add styrene, absolute ethanol and deionized water into the container in sequence according to the volume ratio of 1:5:10 to form a mixed solution, and then add cetyltrimethylammonium bromide to the mixed solution And potassium persulfate, wherein the add-on of cetyltrimethylammonium bromide is 0.5% of the mixed solution quality, is one-time addition, and the add-on of potassium persulfate is 0.1% of the mixed solution quality, when adding Divide into four equal parts, add one part every 1.5h, add cetyltrimethylammonium bromide and potassium persulfate to the reaction mixture completely, and react at 80°C for 6 h under the condition of nitrogen protection to prepare A positively charged polystyrene emulsion with a concentration of 6.25 wt% was prepared, and after the temperature was lowered to room temperature, it was sealed and stored for later use;

[0031] (2) Put chitosan and isopropanol in a round-bottomed flask at a mass ratio of 1:4, heat in a water bath to 85...

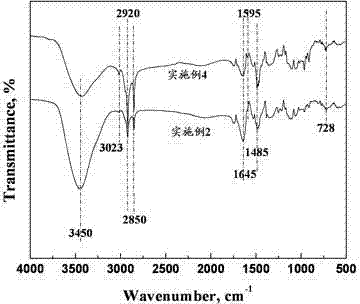

Embodiment 2

[0036] (1) Add styrene, absolute ethanol and deionized water into the container in sequence according to the volume ratio of 1:5:10 to form a mixed solution, and then add cetyltrimethylammonium bromide to the mixed solution And potassium persulfate, wherein the add-on of cetyltrimethylammonium bromide is 5% of the mixed solution quality, is one-time addition, and the add-on of potassium persulfate is 0.25% of the mixed solution quality, when adding Divide into four equal parts, add one part every 1.5h, add cetyltrimethylammonium bromide and potassium persulfate to the reaction mixture completely, and react at 80°C for 6 h under the condition of nitrogen protection to prepare A positively charged polystyrene emulsion with a concentration of 6.25 wt% was prepared, and after the temperature was lowered to room temperature, it was sealed and stored for later use;

[0037] (2) Put chitosan and isopropanol in a round-bottomed flask at a mass ratio of 1:4, heat in a water bath to 85°...

Embodiment 3

[0042] (1) Add styrene, absolute ethanol and deionized water into the container in sequence according to the volume ratio of 1:5:10 to form a mixed solution, and then add cetyltrimethylammonium bromide to the mixed solution And potassium persulfate, wherein the add-on of cetyltrimethylammonium bromide is 3% of the mixed solution quality, is one-time addition, and the add-on of potassium persulfate is 0.2% of the mixed solution quality, when adding Divide into four equal parts, add one part every 1.5h, add cetyltrimethylammonium bromide and potassium persulfate to the reaction mixture completely, and react at 80°C for 6 h under the condition of nitrogen protection to prepare A positively charged polystyrene emulsion with a concentration of 6.25 wt% was prepared, and after the temperature was lowered to room temperature, it was sealed and stored for later use;

[0043] (2) Put chitosan and isopropanol in a round-bottomed flask at a mass ratio of 1:4, heat in a water bath to 85°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com