High-solid-content superhigh-corrosion-resistant water-based epoxy static conductive paint and preparation method thereof

A corrosion-resistant, epoxy-conducting technology, applied in conductive coatings, epoxy resin coatings, anti-corrosion coatings, etc., can solve the problem of difficult to ensure long-term corrosion resistance of oil storage tanks and oil pipelines, shorten system gelation time, epoxy resin Coating brittleness increases and other problems, to achieve good chemical resistance, good physical and mechanical properties, and reduce viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

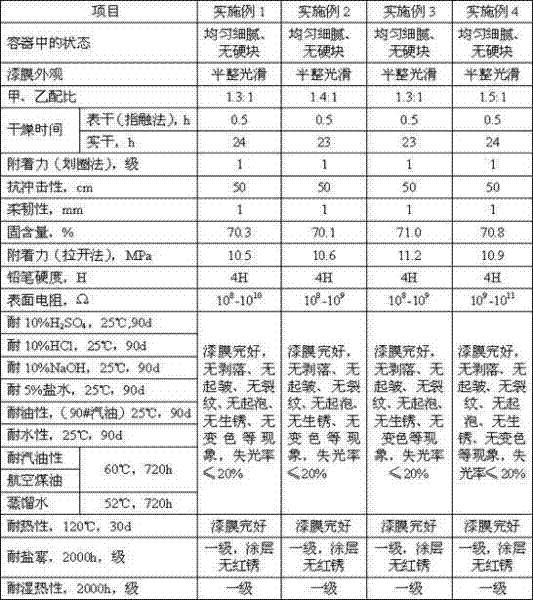

Embodiment 1

[0076] A: deionized water 28.5

[0077] BYK-191 0.5

[0078] SN-154 0.5

[0079] FA-179 0.4

[0080] EU5037 35.0

[0081] Propylene glycol methyl ether 3.7

[0082] Conductive mica powder 28.0

[0083] HALOX BW-191 2.8

[0084] 941PL 0.6

[0085] Glide 410 0.2

[0086] SN-621N 0.2

[0087] B: Modified epoxy resin 50.0

[0088] YJ-P 1.8

[0089] Vapor SiO 2 0.5

[0090] BYK-181 0.4

[0091] TECH 391W 0.4

[0092] Propylene Glycol 5.0

[0093] Packing 16.5

[0094] Among them, A:B=1.3:1

Embodiment 2

[0096] A: Deionized water 25.0

[0097] X840 0.6

[0098] TECH 391W 0.6

[0099] FA-379 0.5

[0100] HTW-208 40.0

[0101] Propylene glycol methyl ether acetate 3.0

[0102] Conductive mica powder 30.0

[0103] HALOX BW-191 3.5

[0104] 941PL 0.8

[0105] M-71 0.3

[0106] TT935 0.2

[0107] B: Modified epoxy resin 52.0

[0108] KDT-90 1.8

[0109] Organic bentonite 0.5

[0110] BYK-181 0.4

[0111] BYK-080 0.4

[0112] Propylene Glycol 5.0

[0113] Packing 16.5

[0114] Among them, A: B=1.4:1

Embodiment 3

[0116] A: Deionized water 28.0

[0117] Surfynol 420 0.6

[0118] SN-154 0.6

[0119] FA-579 0.5

[0120] GCA02 35.0

[0121] Propylene glycol methyl ether acetate 4.0

[0122] Conductive mica powder 30.0

[0123] HALOX SW-111 3.5

[0124] 941PL 0.8

[0125] Glide 410 0.3

[0126] RM-2020 0.2

[0127] B: Modified epoxy resin 53.0

[0128] KDT-90 1.2

[0129] Organic bentonite 0.4

[0130] BYK-181 0.3

[0131] TECH 391W 0.3

[0132] Propylene Glycol 5.5

[0133] Packing 16.5

[0134] Among them, A:B=1.3:1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com