Liquid crystal aligning agent, liquid crystal alignment film, method for forming the liquid crystal alignment film, and liquid crystal display device

A technology of liquid crystal alignment agent and liquid crystal alignment film, which is applied in the direction of liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of large cumulative exposure and insufficient sensitivity, achieve high radiation sensitivity, reduce manufacturing costs, and produce sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0103]

[0104] It is preferable that the liquid crystal aligning agent of this invention melt|dissolves and contains the said polyamic acid or polyimide, and other components arbitrarily mixed as needed in an organic solvent, and is comprised.

[0105] As the organic solvent used in the liquid crystal aligning agent of the present invention, for example, N-methyl-2-pyrrolidone, γ-butyrolactone, γ-butyrolactam, N,N-dimethylformamide, N, N-Dimethylacetamide, 4-Hydroxy-4-methyl-2-pentanone, Ethylene Glycol Monomethyl Ether, Butyl Lactate, Butyl Acetate, Methyl Methoxypropionate, Ethoxypropionate Ethyl ether, ethylene glycol methyl ether, ethylene glycol ethyl ether, ethylene glycol n-propyl ether, ethylene glycol isopropyl ether, ethylene glycol n-butyl ether (butyl cellosolve), ethylene glycol dimethyl ether, ethylene glycol ethyl ether Ester, diethylene glycol dimethyl ether, diethylene glycol diethyl ether, diethylene glycol monomethyl ether, diethylene glycol monoethyl eth...

Embodiment

[0139] Hereafter, although an Example demonstrates this invention concretely, this invention is not limited by these Examples.

[0140]

Synthetic example 1

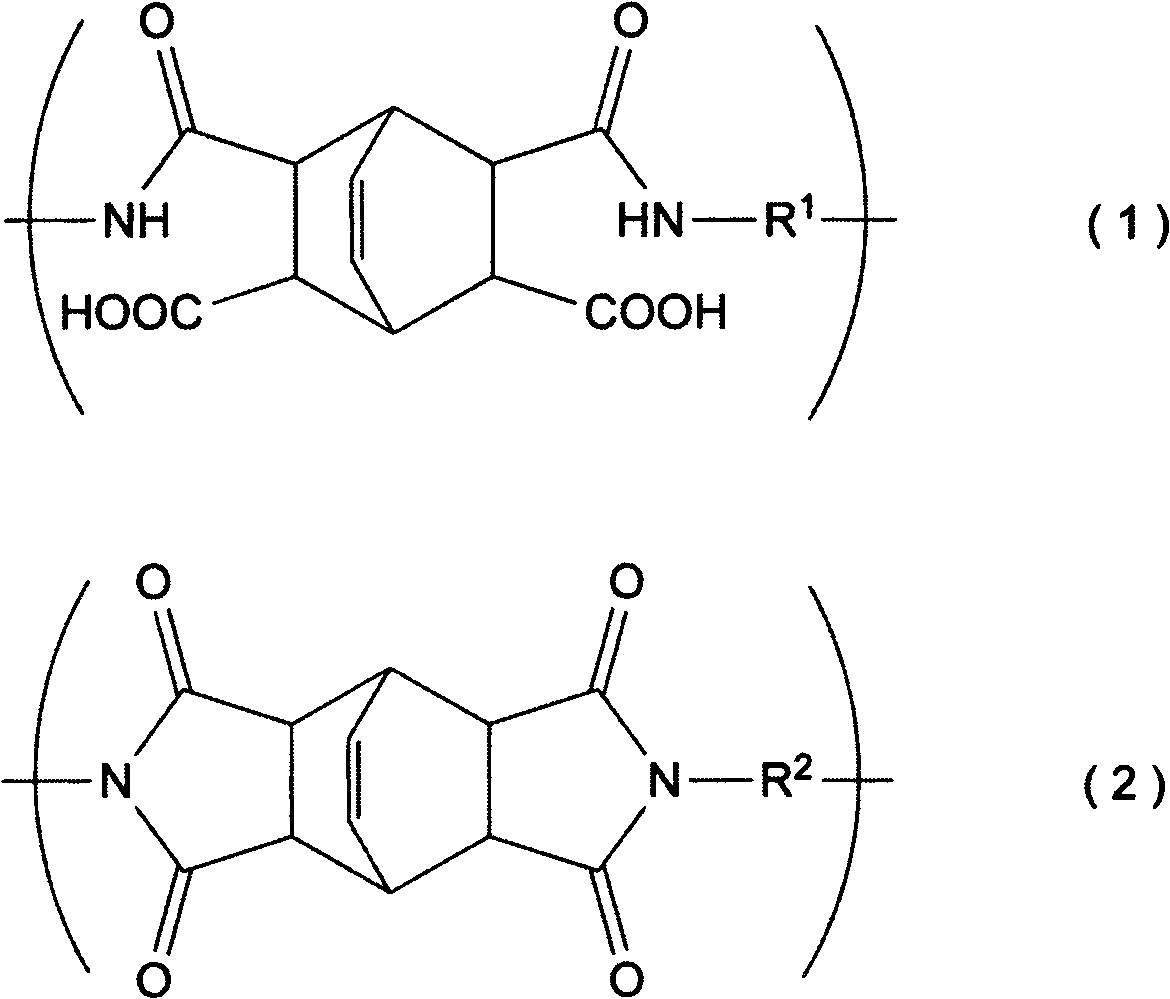

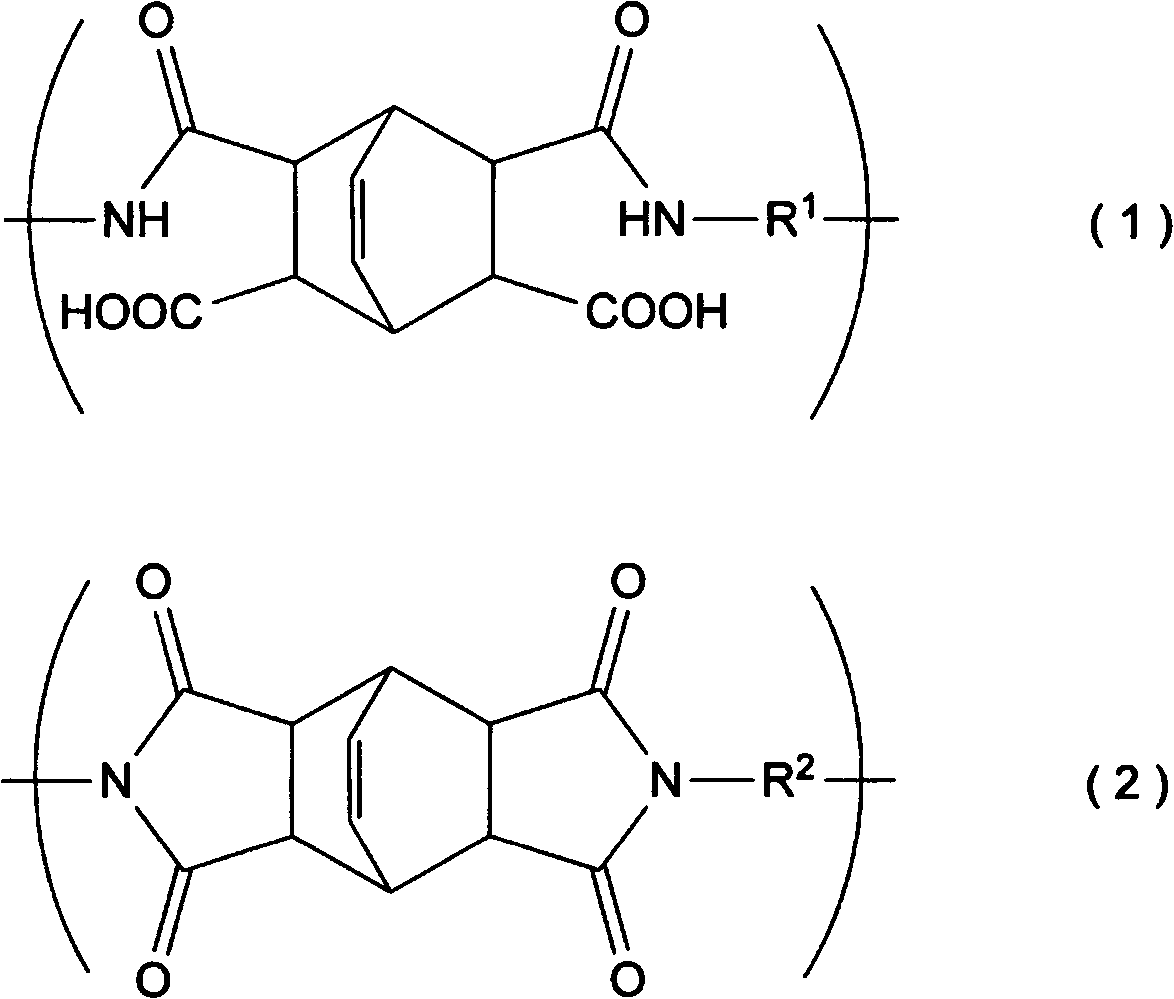

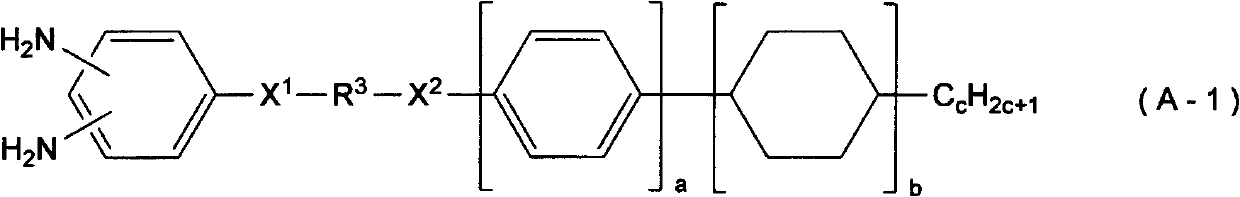

[0142]Dissolve 0.1mol (24.82g) bicyclo[2.2.2]oct-7-one-2,3,5,6-tetracarboxylic dianhydride and 0.1mol (41.05g) in 373.26g N-methyl-2-pyrrolidone 2,2-bis[4-(4-aminophenoxy)phenyl]propane, reacted at room temperature for 6 hours. Next, the reaction mixture was mixed with a very large excess of methanol to precipitate the reaction product. Then, it wash|cleaned with methanol, it dried at 40 degreeC of reduced pressure for 15 hours, and obtained 65 g of polyamic-acid A-1 (yield rate 98.7%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com