Aluminum magnesium alloy intercooler pipes

A technology of aluminum-magnesium alloy and magnesium alloy tubes, which is applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of weld penetration and virtual welding, complex shape, poor mechanical fatigue resistance of stainless steel, etc., and achieve good High temperature pressure resistance and vibration resistance, high plasticity and corrosion resistance, excellent air flow in the tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

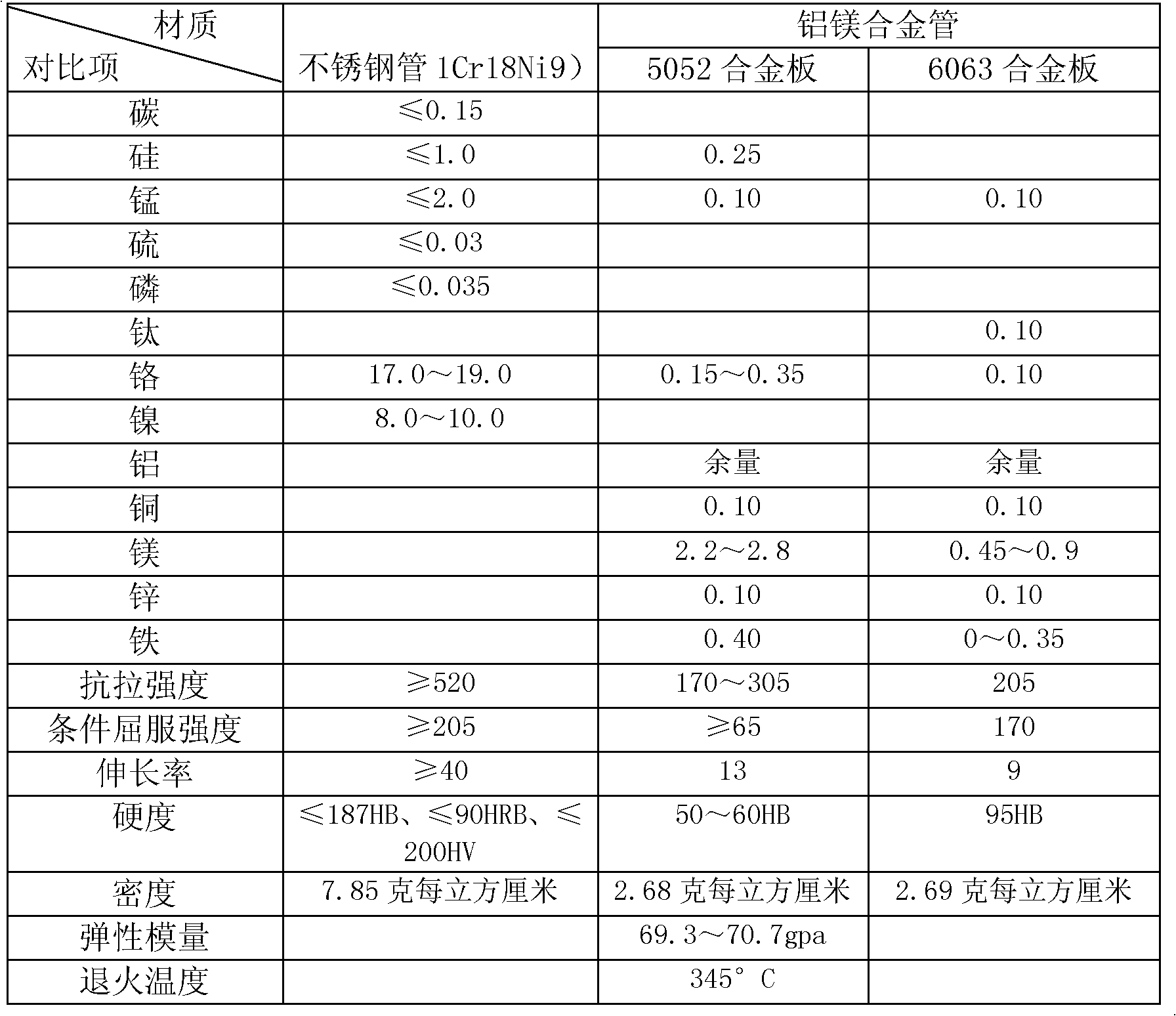

[0019] The aluminum-magnesium alloy intercooler tube of the present invention, the material of the intercooler tube is a magnesium alloy tube, and each intercooler tube is formed by direct bending of an aluminum-magnesium alloy tube, which is an integral body without joints and welds type elbow. In this embodiment, the aluminum-magnesium alloy tube is a 5052 aluminum-magnesium alloy tube or a 6063 aluminum-magnesium alloy tube.

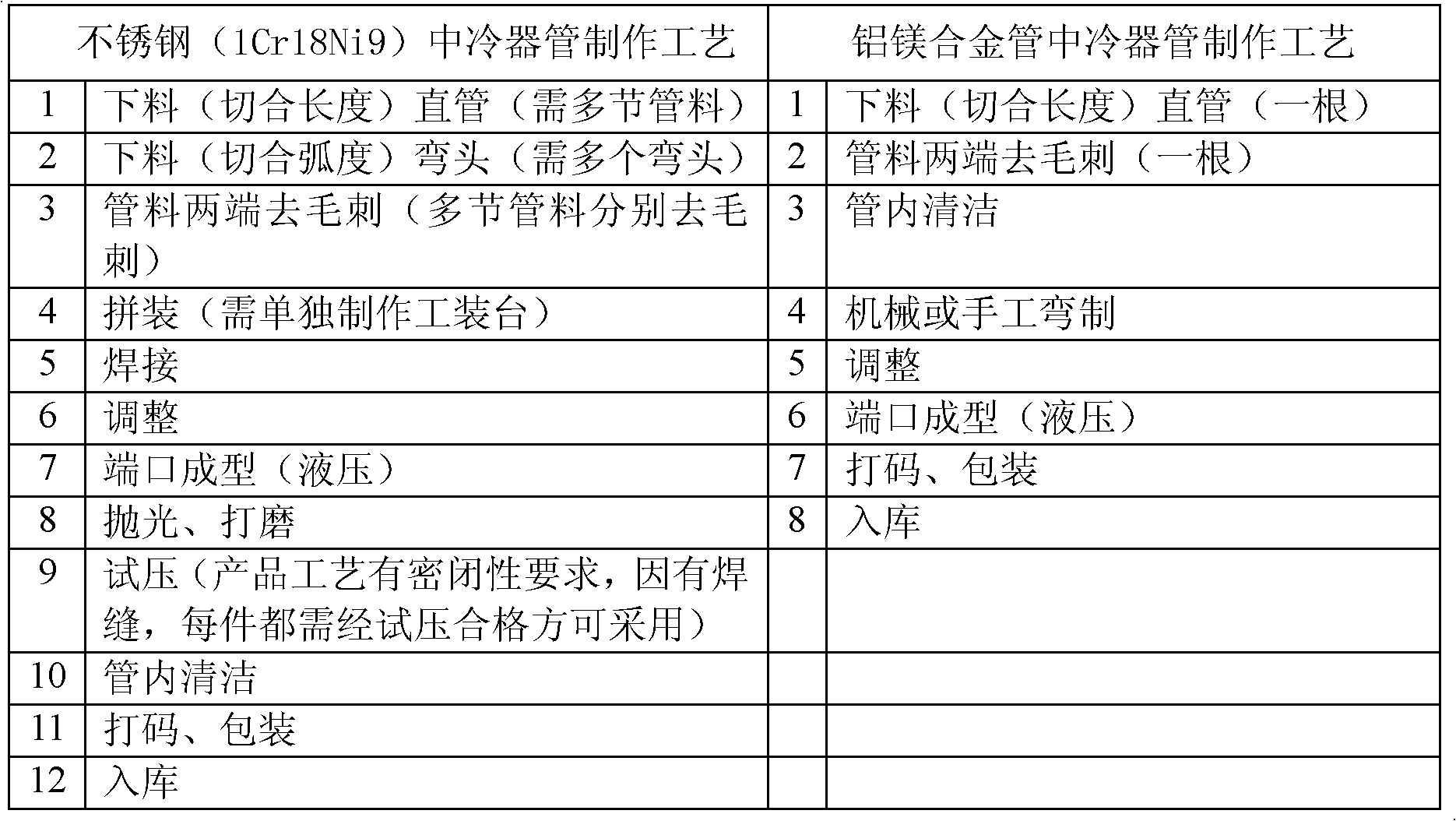

[0020] The following table 2 is the metallographic composition analysis table of stainless steel pipe and aluminum-magnesium alloy pipe fittings.

[0021] Table II:

[0022]

[0023] Since the elongation rate of aluminum-magnesium alloy pipes is superior to that of stainless steel pipes, aluminum-magnesium alloy pipes can be directly bent manually or mechanically. The directly bent aluminum-magnesium alloy tube has no welds, beautiful appearance, no need for splicing, low cost, can effectively increase the output and the service life of the engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com