Method for production of laminate

一种制造方法、叠层体的技术,应用在半导体/固态器件制造、化学仪器和方法、涂层等方向,能够解决基板不容易得到等问题,达到提高发光特性、结晶性好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] hot cleaning

[0107] The sapphire substrate adopts a C-plane substrate inclined 0.15° to the M-axis direction. After setting this on the susceptor in the MOCVD apparatus, the sapphire substrate was heated to 1250° C. while flowing hydrogen at a flow rate of 10 slm, and kept at that temperature for 10 minutes. In addition, in this MOCVD apparatus, a member made of a boron nitride ceramic material is arranged on the surface portion where the sapphire substrate is heated to a temperature of 1000° C. or higher by radiant heat.

[0108] first growth process

[0109] Next, raise the temperature of the sapphire substrate to 950°C, and form a 20nm substrate under the conditions of a trimethylaluminum flow rate of 6.6 μmol / min, an ammonia flow rate of 1 slm, an oxygen flow rate of 0.5 sccm, a total flow rate of 10 slm, and a pressure of 40 Torr. thick AlN initial single crystal layer (formation of the initial single crystal layer). Here, the oxygen source (oxygen-containing ...

Embodiment 2

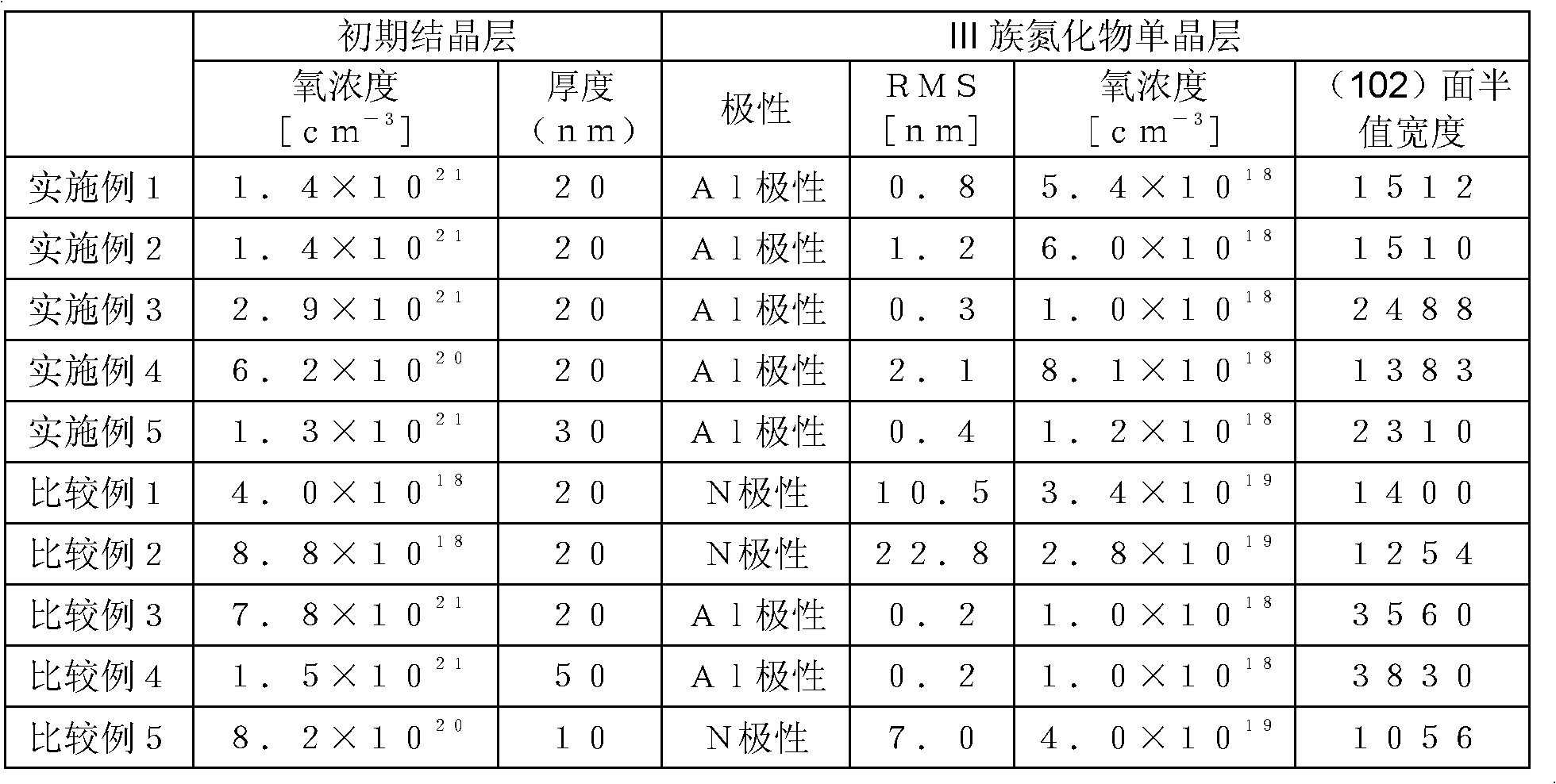

[0116] In order to more accurately analyze the oxygen concentration in the initial single crystal layer of the laminate obtained in Example 1, except that the oxygen used in Example 1 was changed to a stable isotope of oxygen (mass number 18) at 99.9 atomic %, the same A laminate was produced under the same conditions as in Example 1. The obtained results are shown in Table 1.

Embodiment 3

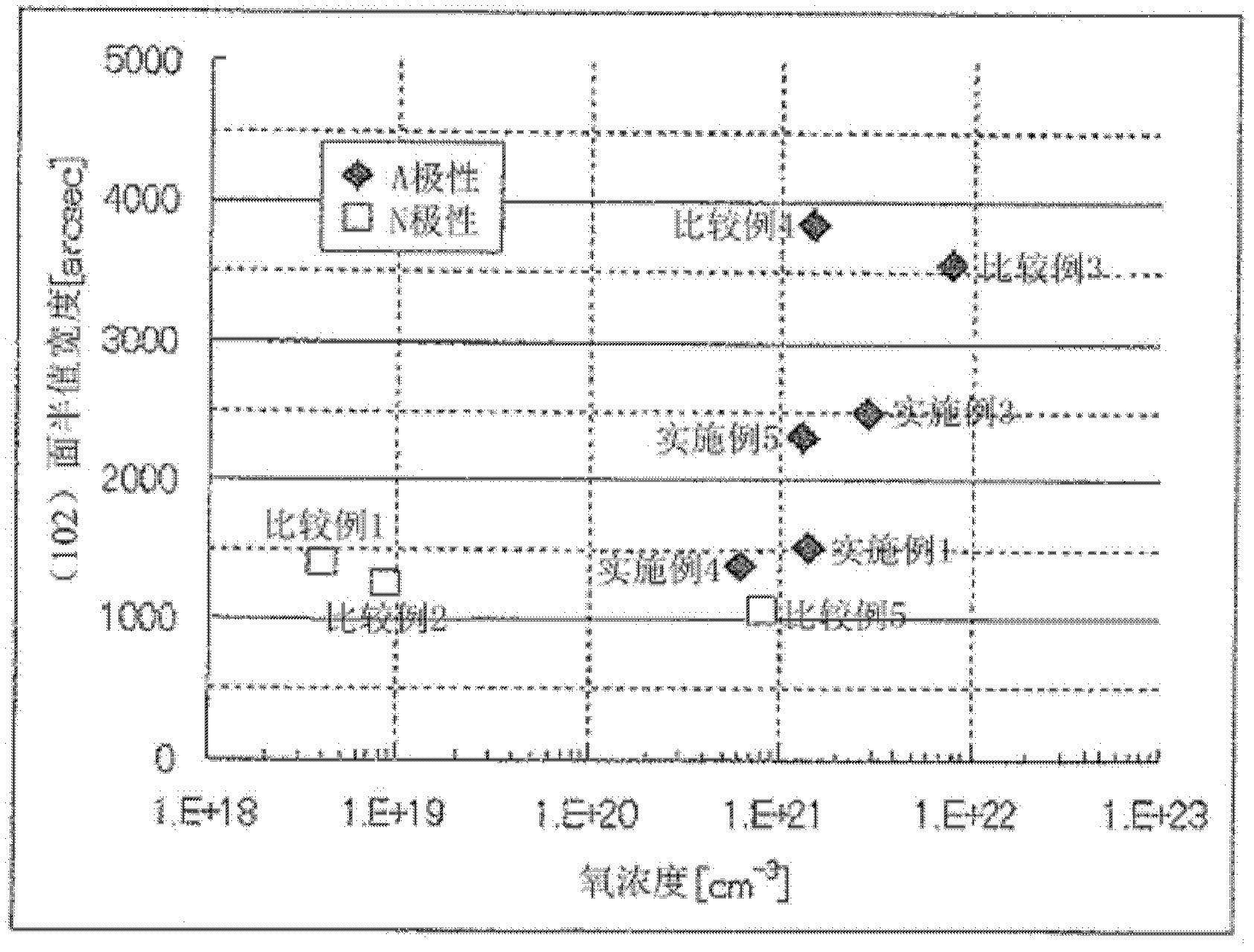

[0118] In the first growth step of Example 1, a laminate was produced under the same conditions as in Example 1 except that the oxygen flow rate was changed to 1.0 sccm. The results obtained are shown in Table 1 and figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| coverage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com