A kind of alginate antibacterial dressing and preparation method thereof

A technology of alginate and sodium alginate, applied in the field of medical biopolymer material science, can solve the problems of the adhesion performance of silver and the surface of the fabric, the peeling off of the surface coating and the base fabric, and the influence of the antibacterial effect of the dressing. The effect of hemostatic ability, promoting wound healing, good water absorption and water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

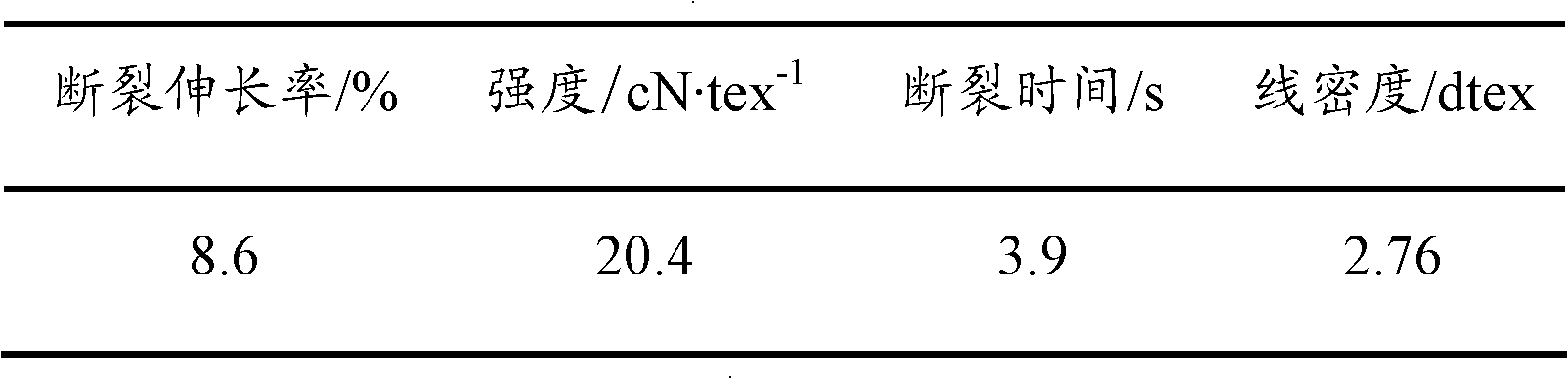

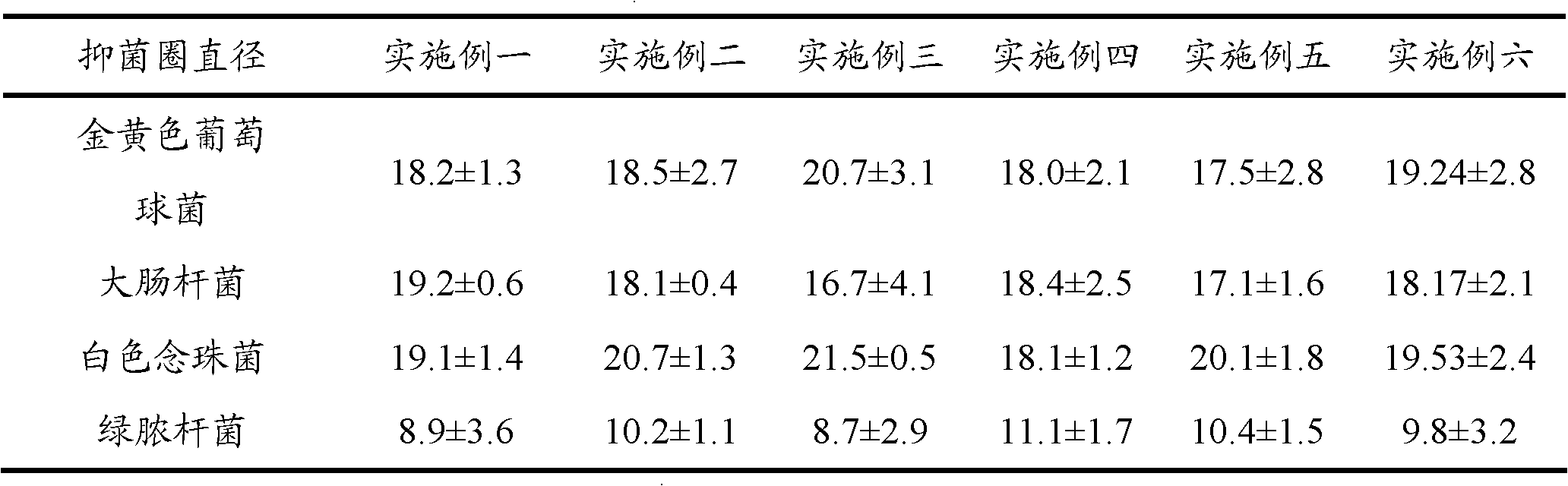

Embodiment 1

[0039] Dissolve sodium alginate and hydroxyethyl chitosan in distilled water at the same time to prepare solutions with mass concentrations of 8% and 10%, respectively, and filter through a filter plate to remove impurities and small insoluble particles in the solution to obtain spinning stock solution; In the coagulation bath of the calcium chloride aqueous solution and ethanol (the volume ratio of calcium chloride aqueous solution and ethanol is 2: 1), add silver-loaded nano-titanium dioxide, make its mass fraction be 6%, stir evenly, and the coagulation bath temperature is 50 ℃; After vacuum degassing in the defoaming kettle, the spinning stock solution is fed with high-pressure nitrogen to feed the spinning stock liquid into the metering pump, and then enters the coagulation bath through the spinneret, and then passes through the coagulation bath for primary stretching and secondary stretching. Wash again to obtain as-spun fibers, and the as-spun fibers can obtain calcium a...

Embodiment 2

[0043] Dissolve potassium alginate and hydroxymethyl chitin in distilled water at the same time to prepare solutions with mass concentrations of 2% and 15%, respectively, and filter through a filter plate to remove impurities and small insoluble particles in the solution to obtain spinning stock solution; In the coagulation bath of calcium chloride solution and ethanol (the volume ratio of calcium chloride aqueous solution and ethanol is 2: 1) in the coagulation bath, add nanometer silver, make its mass fraction be 10%, stir evenly, the temperature of coagulation bath is 30 ℃; After vacuum degassing in the defoaming kettle, the spinning stock solution is fed with high-pressure nitrogen to feed the spinning stock liquid into the metering pump, and then enters the coagulation bath through the spinneret, and then passes through the coagulation bath for primary stretching and secondary stretching. Wash again to obtain as-spun fibers, and the as-spun fibers can obtain calcium algina...

Embodiment 3

[0045] Dissolve ammonium alginate and sulfonate chitosan in distilled water simultaneously to prepare solutions with mass concentrations of 15% and 5%, respectively, and filter through a filter plate to remove impurities and small insoluble particles in the solution to obtain spinning stock solution; at 18% In the coagulation bath of barium chloride solution and ethanol (the volume ratio of barium chloride aqueous solution and ethanol is 1: 1), add silver-loaded nano-titanium dioxide, make its mass fraction be 2%, stir well, and coagulation bath temperature is 65 ℃ ; After vacuum degassing in the defoaming kettle, the spinning raw liquid is fed into high-pressure nitrogen to feed the spinning raw hydraulic pressure into the metering pump, and then enters the coagulation bath through the spinneret, and then passes through the coagulation bath for primary stretching and secondary stretching , and then washed to obtain as-spun fibers, the as-spun fibers can be obtained after natur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com