Oxalate hydrogenation copper-gold dual-metal catalyst and preparation method thereof

A technology of bimetallic catalyst and oxalate, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of rising cost and price, affecting application, and large dosage, so as to reduce dosage and improve activity Little change, promote dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Take the specific surface area prepared in the laboratory to be 783m 2 / g of SBA-15 carrier 2.0g.

[0026] 2) Completely dissolve 0.3g of PVP in 25mL of tetrahydrofuran (THF), pour the above-mentioned carrier into the solution, let it stand for 4 hours, filter, wash and dry to obtain the P-SBA-15 product, which is ready for use.

[0027] 3) Add 0.2g of ethylenediamine (ED) and 20ml of deionized water to the above P-SBA-15 product, reflux at 90°C for 12h, cool to room temperature, rinse with deionized water, and vacuum dry at 60°C to obtain functional group ED-P-SBA-15 solid powder A, spare.

[0028] 4) At room temperature, use a pipette to pipette 7.8 mL of 0.01 g / mL chloroauric acid aqueous solution, dilute it in 100 mL of deionized water, add functionalized ED-P-SBA-15 under stirring, and stir for 10 minutes while stirring Add 0.2M NaBH dropwise 4 20 mL of aqueous solution, the solution changed from yellow to deep purple after 10 minutes, vacuum filtered and was...

Embodiment 2

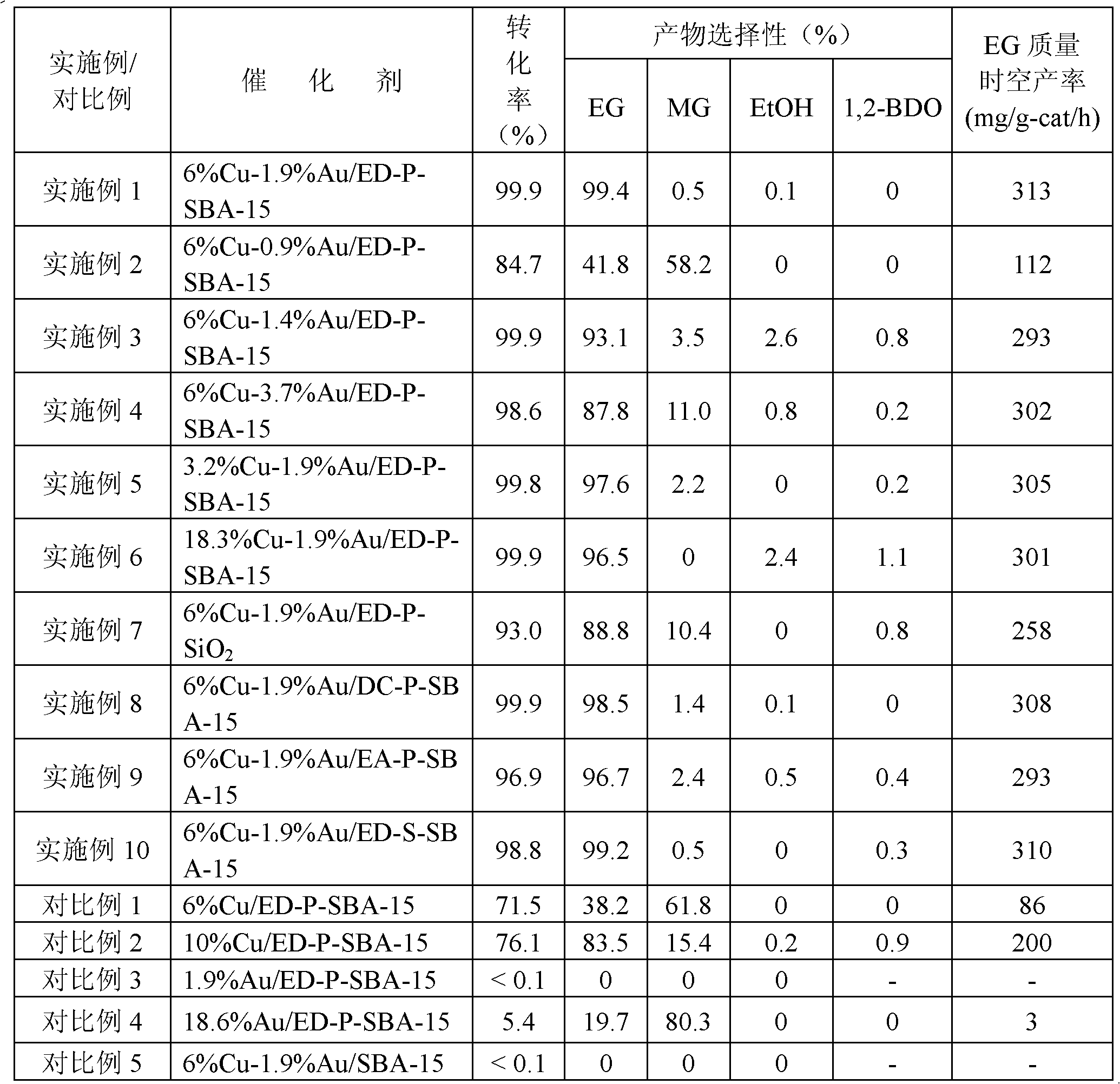

[0035] The preparation method of functionalized ED-P-SBA-15 is the same as that in Example 1. The preparation method of SBA-15 supported bimetallic Cu-Au catalyst is the same as that of Example 1, but the chloroauric acid solution of 0.01g / mL is 3.80mL, and other compositions are unchanged, and 6.0%Cu-0.9%Au / ED-P is obtained -SBA-15 catalyst, the Cu and Au loadings obtained by ICP-OES quantitative measurement are within the error range of the theoretical loadings; the specific surface area is 359m after nitrogen static adsorption test 2 / g, the pore volume is 0.68mL / g, and the average pore diameter is 6.1nm; the metal particle diameter can be calculated as 2.9nm from the electron microscope (TEM) photo of the catalyst. The performance evaluation and product analysis conditions of the catalyst for the hydrogenation of dimethyl oxalate to ethylene glycol are the same as in Example 1, and the results are shown in Table 1.

Embodiment 3

[0037] The preparation method of functionalized ED-P-SBA-15 is the same as that in Example 1. The preparation method of the SBA-15 supported bimetallic Cu-Au catalyst is the same as in Example 1, but the chloroauric acid solution of 0.01g / mL is 5.70mL, and other compositions are unchanged, and 6%Cu-1.4%Au / ED- P-SBA-15 catalyst, the Cu and Au loadings obtained by ICP-OES quantitative measurement are within the error range of the theoretical loadings; the specific surface area is 373m after nitrogen static adsorption test 2 / g, the pore volume is 0.67mL / g, and the average pore diameter is 5.8nm; from the TEM photo of the catalyst, the metal particle size can be calculated as 3.2nm. The performance evaluation and product analysis conditions of the catalyst for the hydrogenation of dimethyl oxalate to ethylene glycol are the same as in Example 1, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com