Interior wall coating coil and preparation method thereof

A technology for interior wall coatings and coils, which is applied to the preparation of interior wall coatings coils, in the field of coils with coating functions, can solve the problems of poor air permeability and flammability of stone paper, and achieve good air permeability, low cost, and high quality stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

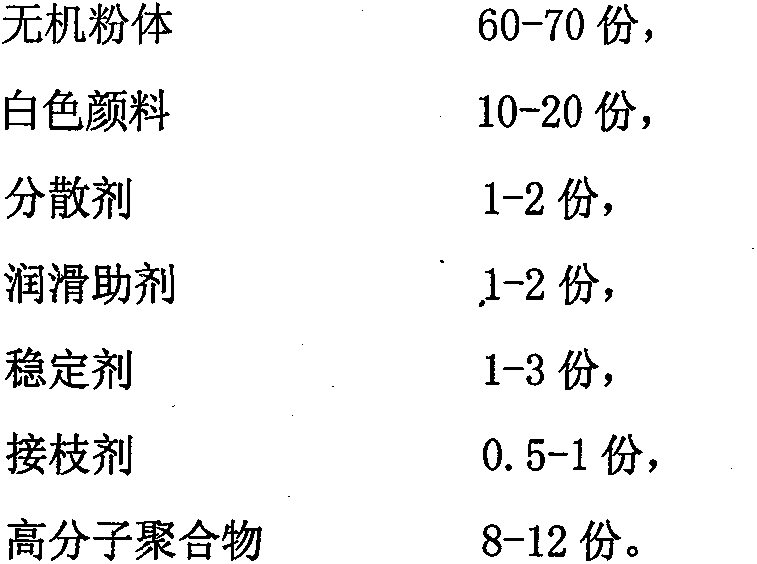

Method used

Image

Examples

Embodiment 1

[0040] 1) Mix 30kg of calcined kaolin, 35kg of light calcium carbonate, 15kg of rutile titanium dioxide, and 1kg of EVA wax in a blender, and add them to a 30-type three-chamber continuous vortex airflow refiner to make the inorganic powder and white pigment The interface is fully contacted and evenly dispersed;

[0041] 2) Introduce the above-mentioned modified material into the L100 high-speed mixer, add 0.5kg maleic anhydride, and react for 15 minutes under the temperature condition of 140°C and 900r / min stirring condition;

[0042]3) Add ethylene bisoleic acid amide 1kg, antioxidant B-(4-hydroxy-3.5 di-tert-butylphenyl) stearyl propionate 0.2kg, light stabilizer 2-( 2'-hydroxyl-5'-tert-octylphenyl)benzotriazole 0.2kg, flame retardant antimony trioxide 0.8kg, reacted for 10min under the temperature condition of 140°C and stirring condition of 900r / min;

[0043] 4) Add 8kg PET into the above-mentioned high-speed mixing equipment and stir and mix evenly;

[0044] 5) The abo...

Embodiment 2

[0047] 1) Mix 25kg of heavy calcium carbonate, 40kg of talcum powder, 5kg of lithopone, 5kg of sharp titanium dioxide, and 1.5kg of Sasol wax in a mixer, and add it to a 60-type three-chamber continuous vortex airflow refiner , so that the interface between the inorganic powder and the white pigment is fully contacted and dispersed uniformly;

[0048] 2) Introduce the above-mentioned modified material into the L100 high-speed mixer, add 0.1kg maleic anhydride and 0.5kg polybutylacrylic acid, and react for 30min at a temperature of 80°C and stirring at 900r / min;

[0049] 3) Add stearic acid amide 0.5kg, ethylene bisstearic acid amide 1.0kg, antioxidant tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propane to the above-mentioned high-speed mixer Acid] pentaerythritol ester 0.3kg, light stabilizer bis(2,2,6,6,-tetramethyl-4-piperidinyl) sebacate 0.3kg, flame retardant magnesium hydroxide 1.2kg, at 120°C Reaction for 8 minutes under temperature conditions and 1000r / min stirring c...

Embodiment 3

[0054] 1) Mix 30kg of sericite, 30kg of wollastonite, 5kg of lithopone, 5kg of rutile titanium dioxide, and 1.5kg of oxidized polyethylene wax in a blender, and add it into a 45-type three-chamber continuous vortex airflow refiner, Make the interface of inorganic powder and white pigment fully contact and disperse evenly;

[0055] 2) Introduce the above-mentioned modified material into the L100 high-speed mixer, add 0.2kg methyl methacrylate and 0.5kg polybutylacrylic acid, and react for 20min under the temperature condition of 100°C and stirring condition of 1500r / min;

[0056] 3) Add 1.5 kg of glyceryl monostearate, 0.4 kg of antioxidant tris(2,4-di-tert-butylphenyl) phosphite, and light stabilizer 2-hydroxyl-4-methanol in the above-mentioned high-speed mixer. 0.4kg of oxybenzophenone and 1.6kg of flame retardant aluminum hydroxide were reacted at 120°C and 1500r / min stirring for 5min;

[0057] 4) Add 12kgLDPE into the above-mentioned high-speed mixing equipment and stir an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com