Positive temperature coefficient material, preparation method thereof and thermistor containing positive temperature coefficient material

A positive temperature coefficient, thermistor technology, applied in the direction of resistors with a positive temperature coefficient, etc., can solve the problem of anti-aging performance, voltage resistance and current resistance performance not meeting the requirements, high operating current and voltage, thermistor Problems such as not being able to use normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a method for preparing a positive temperature coefficient material, comprising the following steps:

[0020] 1) Mix additives, nucleating agents, and polymers in an extruder and cut them into mixture I with a particle diameter of 4 mm;

[0021] 2) Fully mix the titanate-modified conductive filler and titanate-modified flame retardant in a high mixer to obtain mixture II;

[0022] 3) mixing mixture I, mixture II and lubricant in an internal mixer to obtain a positive temperature coefficient thermistor material;

[0023] Wherein, based on the total weight of the mixture I, II and the lubricant, based on the total weight of the mixture, the content of the additive is 0.5-10 wt%, and the content of the polymer is 5-15 wt%, The content of the nucleating agent is 0.5-10wt%, the content of the lubricant is 0.5-3wt%, the content of the titanate-modified conductive filler is 80-90wt%, the content of the titanate-modified flame retardant is 1- 6wt%; the a...

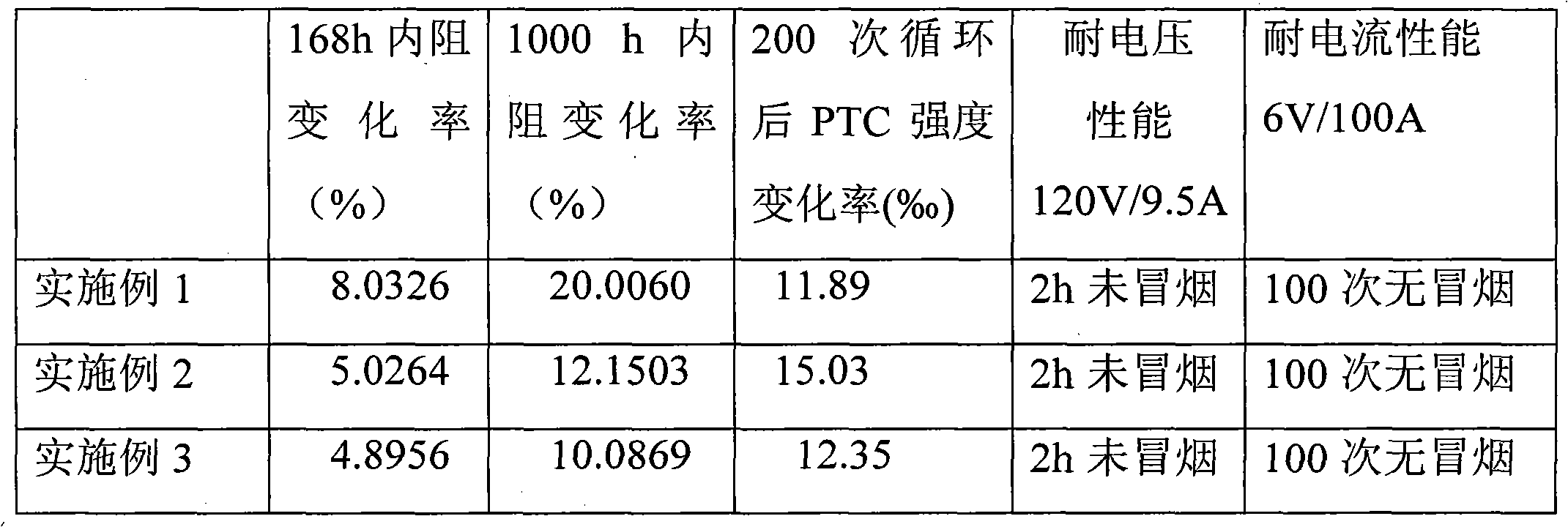

Embodiment 1

[0042] This embodiment is used to illustrate the preparation of the positive temperature coefficient material and thermistor of the present invention.

[0043] By mixing 2% ethylene-octene copolymer, 2% EPDM, and 10% high-density polyethylene resin that account for the positive temperature coefficient material to obtain a mixture, the mixture obtained above is sent into a twin-screw compounding extruder ( In SJSH-30 type, Nanjing Rubber and Plastic Machinery Factory), the length-to-diameter ratio of the extruder is L:D=36:1, and the screw diameter is Φ53 mm. Adjust the rotation speed of the screw to 400 rpm, and divide it into 5 sections from the feed end to the discharge end, and control the temperature of each section at: 170°C; 175°C, 180°C, 185°C, 185°C; The vacuum degree of the mixture is maintained at 0.05 to 0.08 MPa; under the above conditions, through melt extrusion and granulation, mixture I is obtained; 80% titanate modified nickel powder, 4% titanate modified magne...

Embodiment 2

[0047] Mix 0.5% ethylene-octene copolymer, 0.5% EPDM, and 15% polyethylene resin, which account for positive temperature coefficient materials, to obtain a mixture, and send the above-mentioned mixture into a twin-screw compounding extruder (SJSH- Type 30, Nanjing Rubber and Plastic Machinery Factory), the length-to-diameter ratio of the extruder is L:D=36:1, and the screw diameter is Φ53 mm. Adjust the rotation speed of the screw to 400 rpm, and divide it into 5 sections from the feed end to the discharge end, and control the temperature of each section at: 170°C; 175°C, 180°C, 185°C, 185°C; Keep the vacuum degree of 0.05 to 0.08 MPa; under the above conditions, through melt extrusion granulation, to obtain the mixture I; 82% of titanate modified carbon black, titanate modified 1% of alumina in Mix at room temperature (25° C.), first at 800 rpm for 20 minutes, then at 2000 rpm for 3 minutes to obtain mixture II. Finally, mixture I, mixture II and 1% zinc stearate were mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com