Preparation method for nano-copper ink applied to printed electronics

A nano-copper and conductive ink technology, applied in ink, printing, application and other directions, can solve the problems of high heating temperature, easy agglomeration of copper, complicated process, etc., and achieve the effect of low sintering temperature, good conductivity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

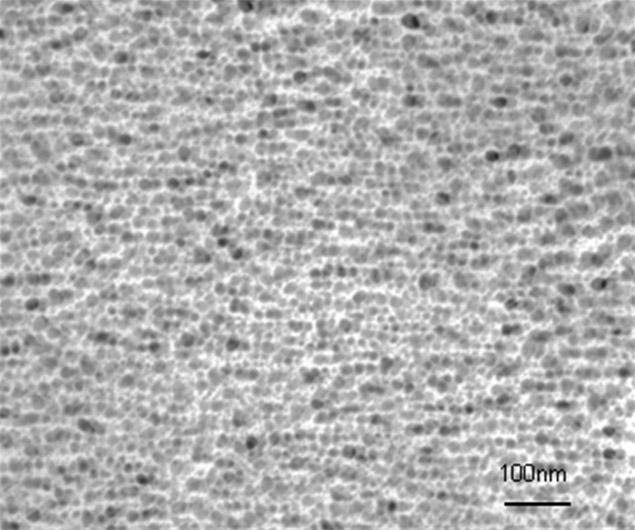

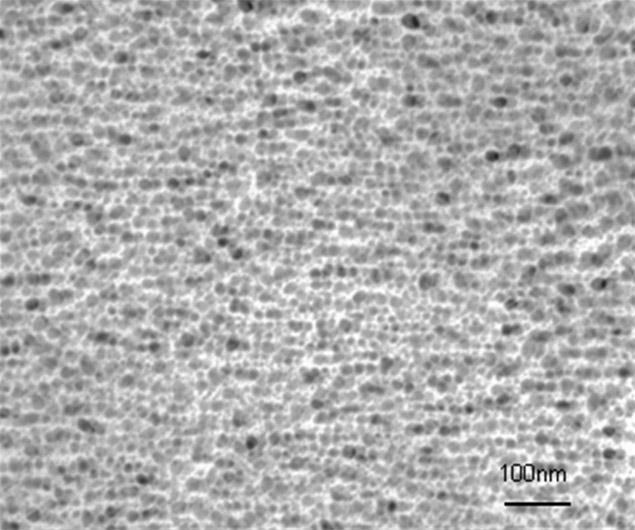

[0020] Example 1: Dissolve 0.01mol of copper acetate in 30ml of water, add 2ml of lactic acid, stir to dissolve, continue to stir for 20 minutes, then add ammonia water, the solution turns from blue to dark blue purple, continue to stir for 60 minutes, then add 10ml of hydration drop by drop Hydrazine, the solution gradually turns dark red, indicating that nano-copper is generated, and it is ready for use after continuous stirring and reaction for 25 minutes.

Embodiment 2

[0021] Example 2: Dissolve 0.01mol of copper acetate in a mixed solution of 15ml of water and 15ml of ethanol, add 2ml of lactic acid, stir to dissolve, continue to stir for 25 minutes, then add ammonia water, the solution turns from blue to deep blue purple, continue to stir for 50 minutes , and then add 10ml of hydrazine hydrate dropwise, the solution gradually turns dark red, indicating that nano-copper is formed, and the reaction is continued for 35 minutes after stirring.

Embodiment 3

[0022] Embodiment 3: Dissolve 0.01mol copper acetate in 30ml water, add 2ml ethanolamine, after stirring for 20 minutes, add ammonia water, the solution changes from blue to dark blue purple, continue stirring for 55 minutes, then add 10ml hydrazine hydrate dropwise, the solution gradually becomes It turns dark red, indicating that nano-copper is generated, and it is ready for use after continuous stirring and reaction for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com